Z12 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z12 BMP Prepainted Rolled Steel Coil for Construction

Description of Z12 BMP Prepainted Rolled Steel Coil for Construction

CR steel sheets have good processability, with good flatness and excellent surface, are available with different thickness and width combinations; are mainly used to manufacture the high value-added products in automotive and appliance, beverage packaging, electronic, electrcial moor and building etc. The CR steel sheet include the oncoated steel steel , galvanzied steel sheet, tin plate and TFS, precoated steel sheet and electrical steel steel, etc.

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Main Feature of Z12 BMP Prepainted Rolled Steel Coil for Construction

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Applications of Z12 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

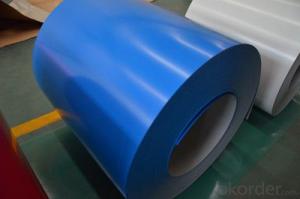

Specifications of Z12 BMP Prepainted Rolled Steel Coil for Construction

Product | Z12 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z12 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel coils used in the manufacturing of automotive wheels?

- Steel coils are used in the manufacturing of automotive wheels as the primary raw material. These coils are first processed through a series of cutting, bending, and shaping processes to form the wheel rims. The steel's strength and durability make it an ideal material choice for withstanding the weight and stresses of a vehicle. Additionally, the coils undergo various heat treatment and finishing processes to enhance their resistance to corrosion and provide a smooth surface for painting or coating. Ultimately, steel coils play a crucial role in the production of automotive wheels, ensuring their structural integrity and performance on the road.

- Q: Climbing ropes used by mountaineers are usually made of nylon. Would steel cable of equal strength as the nylon be just as good? What advantages and disadvantages would it have compared to the nylon?

- steel is NOT as flexible and much slipperier if you fall the nylon stretches to slow the victim but a steel cable would stop short and kill you

- Q: What are the different types of steel coil storage locations?

- There are several different types of steel coil storage locations, including warehouse storage, outdoor storage yards, rack storage systems, and automated storage systems.

- Q: What are the different types of steel coil cutting tools?

- There are several types of steel coil cutting tools, including slitting shears, rotary slitters, flying shears, and laser cutters. Each tool is designed to cut steel coils into specific shapes and dimensions, depending on the desired end product.

- Q: How are steel coils used in the production of shelving units?

- Steel coils are used in the production of shelving units by being processed and formed into various components such as shelves, brackets, and support beams. These coils are typically cut, bent, and welded to create the necessary shapes and sizes required for the shelving unit. The steel material provides strength and durability to the shelves, ensuring they can hold heavy items and withstand the weight placed on them.

- Q: Can steel coils be coated with anti-corrosive substances?

- Yes, steel coils can be coated with anti-corrosive substances to protect them from rust and corrosion.

- Q: and what are the four main elements in STAINLESS steel? x

- decreasing the carbon content fabric will strengthen the ductility, which will make it greater versatile. Carbon in metallic varieties brittle cementite (iron carbide) which will strengthen the hardness and capability of metallic.

- Q: How do steel coils contribute to the water and wastewater industry?

- Steel coils are an essential component in the water and wastewater industry as they play a crucial role in the construction and maintenance of infrastructure. These coils are made from high-quality steel, which offers numerous advantages for the industry. Firstly, steel coils are used in the manufacturing of pipes and tubes that are primarily used for transporting water and wastewater. Steel pipes are known for their exceptional strength and durability, allowing them to withstand high pressure and heavy loads. This makes them ideal for water distribution systems, sewage networks, and treatment plants. Steel coils provide the necessary material for the production of these pipes, ensuring a reliable and long-lasting infrastructure. Moreover, steel coils are also utilized in the construction of storage tanks and reservoirs. These tanks are essential for water treatment plants, where they store large volumes of water or wastewater during the treatment process. Steel coils provide the necessary material for the fabrication of these tanks, ensuring their structural integrity and preventing leaks or contamination. Additionally, steel coils are used in the manufacturing of various equipment and components used in the water and wastewater industry. For instance, steel coils are utilized in the production of pumps, valves, and control systems, which are crucial for the efficient operation of water treatment plants, pumping stations, and sewage networks. Steel's strength and corrosion resistance make it an ideal material for these applications, ensuring reliable and long-lasting equipment. Furthermore, steel coils are also employed in the construction of wastewater treatment plants and facilities. These plants employ various processes to remove contaminants from wastewater before it is discharged into the environment. Steel coils provide the necessary material for the construction of these facilities, including structural supports, tanks, and other components. The durability and resilience of steel ensure the longevity and efficiency of these treatment plants. In summary, steel coils are integral to the water and wastewater industry due to their contribution to the construction and maintenance of critical infrastructure. They are used in the manufacturing of pipes, tanks, equipment, and facilities, ensuring the strength, reliability, and durability necessary for the efficient operation of water and wastewater systems.

- Q: On a fixie frame what should i get an aluminum frame or a steel frame

- Steel will ride smoother, but be heavier. Aluminum is lighter, but you will feel more of the small bumps in the road. IMHO - steel is real - but only on a road bike with gears for around town or touring. Fixed gear bikes? You can keep 'em. I wouldn't own one if it were free.

- Q: What are the different types of steel coil packaging systems?

- There are several types of steel coil packaging systems available, including horizontal coil packaging machines, vertical coil packaging machines, and coil wrapping machines. Each system is designed to securely package steel coils for transportation and storage, ensuring their protection from damage and corrosion.

Send your message to us

Z12 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords