WPC Decking/high quality Recycled Plastic WPC Decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

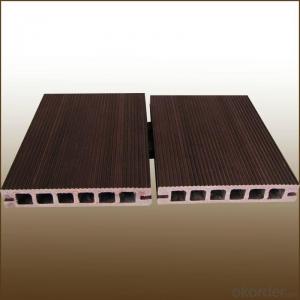

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: Such as title. Best to be detailed.

- At present, China's PVC flooring production is in a period of development, especially PVC sheet flooring (stone floor) production of domestic technology has been very mature, the country has a lot of well-known brands, production technology and quality are relatively high, many brands a large number of exports , Many foreign PVC floor manufacturers are also a large number of factories in China, especially South Korea has a lot of manufacturers set up factories in China production. Some of the big brands of manufacturers will also own sheet flooring production line to China for production, and then sold back to the rest of the world. PVC flooring production technology alone is not yet mature, can only make a fake article, some key technology domestic floor manufacturers can only rely on imports, the product still has serious flaws, although there are foreign brands of manufacturers in China set up production , But the key technology is produced in foreign countries. If you want to introduce PVC flooring production line, I suggest you or the introduction of coil flooring production line as well. Because our country's PVC sheet flooring demand is very large, especially in the low-end PVC coil flooring market is very large.

- Q: I dont think they are sealed as they scratch really fast. What can I use thats safe/cleans/polishes the shine back to my dull floors? Floors were installed when we moved about 2 years ago. Thanks

- Do you mean laminate floors? If so, these links will give you the information you need.

- Q: Do you have to pay VAT and excise tax on solid wood flooring?

- need. Tax rate: VAT is paid in the production process and sales links, the consumption tax is only paid in the production process. VAT rate, the general taxpayer 17 can offset the entry, small taxpayers when 3% is not deductible. According to the financial and taxation [2006] 33 document, solid wood flooring for the new consumption tax items, the applicable tax rate of 5%. The consumption tax on solid wood flooring, reflecting the national policy of protection of timber resources. Calculation: VAT on real wood flooring, tax payable = sales × tax rate - input tax. On the solid wood floor levy consumption tax, the implementation of ad valorem rate approach, tax payable = sales × tax rate. Assuming that the plant sold solid wood flooring in April 1 million, the initial calculation of the tax payable is 100 × 5% = 5 (million). Pay attention to save the deduction certificate. External solid wood flooring, should provide special VAT invoices (deduction) original and copy. If the special invoice is filled out, you should also provide the original and printed copy of the sales list issued by the seller and stamped with the financial seal or invoice. From the small value-added taxpayers to purchase solid wood flooring, should provide tax authorities on behalf of the open value-added tax invoices.

- Q: What are the advantages and disadvantages of solid wood flooring?

- Solid wood composite flooring advantages and disadvantages are the following: 1) solid wood flooring retains the solid wood flooring natural texture, foot feel comfortable features. 2) solid wood flooring and both strengthen the floor wear, easy to install, clean up the characteristics. 3) I solid wood flooring is very suitable for warm home decoration. 4) solid wood composite floor hardness than the floor is very small, very suitable for home with the elderly and children decorated family. 5) Solid wood flooring prices between the solid wood flooring and solid wood flooring of the method of prostitutes prostitutes 诓 magic ride between Wei and glass, belonging to the middle consumption of water balance, is the majority of the family can accept the scope of consumption. 6) solid wood flooring installation is simple, easy to clean up, no solid wood flooring so delicate. 7) solid wood flooring decoration effect is very good, many varieties, such as: solid wood composite antique floor, solid wood parquet flooring. Solid wood flooring is the lack of places: solid wood flooring is made of multi-layer floor, will contain a small amount of formaldehyde.

- Q: My family is preparing to decorate, is considering the floor or floor tiles, we intend to live with the room with the room is also a rough dwarfed gnome dumplings evil spear pave the floor, but a friend said my house east-west, sunny, afraid of the floor can not stand Alice Is it really like this? There is a large living room area, the floor is assembled. Easy to loose more

- 1, good composite floor to withstand the sun is no problem. 2, the large floor of the proposed use of the lock structure of the composite floor, it is not easy to loose.

- Q: The home is ready to be renovated, the mother and I are lying on the floor tile or composite floor serious differences I tend to composite floor,

- For the use of tiles and flooring from the two aspects of the first analysis, from the design point of view 1. In the design will be divided into open space and open space space, that is, the living room and bedroom from the visual point of view, Angle on the separation. 2. In the living room in the guest effect, the tiles are more reasonable, even now the quality of the Chinese people are generally improved, but there will be some people do not like to take someone else to take off their shoes, and then we can not friends Refused to thousands of miles away, so the tiles can be a good body of the United States and the United States and the United States and the United States, the United States, the United States, the United States, the United States, the United States, the United States and the United States, The floor in the space to refuse the entry of others. Second, from a practical point of view 1. Tile in the use of dirt, water scrubbing the advantages are very high, so even if some of the parties in the party can also be easily removed. 2. Wood flooring its own characteristics can not be used, and long time cleaning will cause deformation. But the wood floor of their own comfort, and quiet can also be a good embodiment of the bedroom.

- Q: Or solid wood (also see what the wood, such as two-winged beans, etc.), but the composite price is better, not easy to change, good care.

- It is recommended to remove the original floor, and then re-install the new floor. There are several reasons for the following reasons. 1, environmental protection: even if the special green sheet, there are formaldehyde. If blindly superimposed artificial plate, plant Shan class to catch the non-stumbling stone leopard will be excessive. 2, for the floor is certainly not satisfied with the original floor, and perhaps just did not fancy color. But does not rule out the place where there are wear and damage, these places if covered under the new floor, easy to absorb moisture deformation, affecting the installation and use of the new floor effect. 3, because it is the old house, it is best to be able to remove the old floor, you can thoroughly clean. And can look at the original ground conditions, is not needed from the new ground flat. 4, the old floor to install a new floor, due to elevation, it is likely to cause the gap under the gap. Or other aspects of the relevant decorative items modified.

- Q: What is the difference between solid wood flooring, laminate flooring and laminate flooring? The

- Upstairs is very complete explanation. However, the combination of solid wood is also applicable to the geothermal!

- Q: I recently just installed engineered wood click-lock flooring (floating) over plywood subfloor on our second floor and I noticed some hollow or bounce spots near the entry of the room. The subfloor is plywood and it has a layer of foam underlayment on top and then the flooring. Question: to fix this problem, can I just nail some high spots down to the plywood? I really want to avoid redoing the whole room if possible. What are some other options that I have? The subfloor is not perfectly leveled but it is pretty leveled (I sanded them).

- yes you can and that's about all you can do. make sure you use finish nails, I use ringshanks, (paneling nails) and drive them in between the joints to hide them. p.s. you don't really have options now. leveling is top priority, now that's too late, however, they all have some high spots, I don't install them anymore, I hate them.

- Q: New house ready to renovate, bedroom inside want to use composite floor, but I heard that the composite floor radiation, is true or false ah? The The More

- No radiation! Korean and Japanese heating is very developed, the vast majority of residents shop is solid wood flooring. I began to learn nothing about the floor, and later through the study, found the solid wood flooring is the best choice for the following reasons: We all know solid wood flooring (solid wood flooring) in addition to the advantages of solid wood flooring Such as: not easy to deformation anti-Alice, good maintenance, not Jiaoqi, etc.: ① solid wood flooring substrate is more than Liu amine, breathable, comfortable better; ② with the amount of plastic The use of ceramic lacquer, wear resistance are better, but also the use of ceramic paint, But not as strengthen the composite; ⑤ not Jiaoqi, good care. It has a good moisture resistance, because its substrate is the use of criss-cross the willow wood pressed from the wood to eliminate the internal stress. The same solid wood flooring brand a lot, but they have a small production line brand, but also the use of OEM (OEM). Note: the purchase of the floor is not harder the better, because the harder texture, the foot feel worse, and lost the wood itself, sound absorption, moisture and other advantages. Some businesses often use some metal objects to cut the floor to the floor from damage as well, this is just a business promotion gimmick. We know the most obvious truth: the wood must be afraid of iron (the two of the molecular structure is not the same), on the contrary not afraid of the floor of the iron is not necessarily pure wood products. I hope you will not be misled by the advertising of the business. To know the statistics on the floor in terms of complaints, 100 complaints, because the wear problem even one is not, very simple reason ... ... who will be wearing their own high heels will be free to step on it? Or use metal hard objects to knock on their own floor it? The So the real problem is that the floor is cracking, deformation and so on.

Send your message to us

WPC Decking/high quality Recycled Plastic WPC Decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords