Geotextile Factory Woven Fabric Anti Mat Groundcover

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Anti Mat Fabric Description:

Anti Mat Fabric is made of environmentally friendly raw materials, pp woven fabric. It used to prevent the growth of weed.

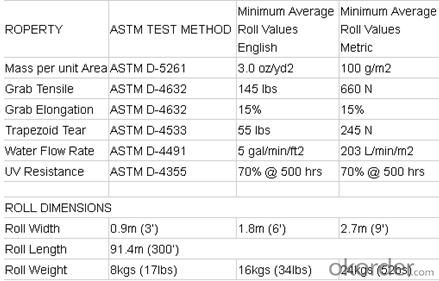

2. Anti Mat Fabric Specification:

3. Anti Mat Fabric Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

8)Ideal for use in landscaped beds,under decks and walkways

4. Anti Mat Fabric Property:

1) Light weight, high strength, low elongation, easy to construct.

2) Reinforcement, separation, drainage and filtration, fencing function, etc.

5. Anti Mat Fabric Application:

It can be widely used in areas of railways, highways, sport fields, earthwork, etc.

6. FAQ:

Q1:Can you send samples to us ?

A1:Yes , free samples could be provided , but customer need pay for the freight cost . After order placed , the freight charge could be refund .

Q2:What’s your Payment term ?

A2:T/T , L/C , Western Union,Paypal ...

Q3:What’s your manufacture process time ?

A3:Usually within 20 days

- Q: What are the key factors affecting the permeability of geotextiles?

- The key factors affecting the permeability of geotextiles include the fabric structure and composition, thickness, porosity, and pore size distribution. The type and arrangement of fibers or filaments, as well as the presence of any coatings or additives, can also impact permeability. Additionally, factors such as compaction, moisture content, and pressure can influence the ability of geotextiles to allow water or fluids to pass through.

- Q: How to build a good geotextile sales team

- Any industry needs talent, geotextile sales staff do not need a high degree of education, can work hard on the line, I am specializing in the production of geotechnical materials, wish smooth

- Q: What are the key considerations for geotextile installation in high water flow areas?

- Some key considerations for geotextile installation in high water flow areas include selecting a geotextile material with a high flow rate to allow for effective water drainage, ensuring proper anchoring and securing of the geotextile to prevent displacement, conducting thorough site investigations and assessments to determine the appropriate installation method and design, and monitoring the performance of the geotextile over time to identify any maintenance or repair needs. Additionally, considering the environmental conditions and potential impact on the geotextile's durability is crucial in high water flow areas.

- Q: Woven geotextile is not considered a spinning geotextile

- Woven geotextile is made of textile technology is a spinning geotextile.

- Q: Why do you want to wrap the geotextile

- Filter function, filter function, I am specializing in the production of geotechnical materials

- Q: Can geotextiles be used in golf course construction?

- Yes, geotextiles can be used in golf course construction. Geotextiles are commonly used in various applications in golf course construction, such as stabilizing soil, preventing erosion, and improving drainage. They can help enhance the performance and longevity of golf course infrastructure, such as greens, tees, bunkers, and fairways.

- Q: What are the different geotextile performance properties?

- Some of the different geotextile performance properties include filtration, separation, drainage, erosion control, reinforcement, and cushioning.

- Q: How do geotextiles help with soil stabilization?

- Geotextiles help with soil stabilization by acting as a physical barrier that prevents soil erosion and the displacement of soil particles. They provide support to the soil, distribute load stresses, and improve the overall stability of the ground. Additionally, geotextiles promote water drainage and filtration while preventing the loss of fine soil particles, thereby enhancing soil quality and preventing erosion-induced damage.

- Q: Can geotextiles be used in the construction of agricultural ponds?

- Yes, geotextiles can be used in the construction of agricultural ponds. Geotextiles are permeable fabrics that can be used to separate, filter, reinforce, or drain soils in various construction applications. In the case of agricultural ponds, geotextiles can be used to prevent soil erosion, stabilize slopes, and provide protection against punctures or tears in the pond lining. Additionally, geotextiles can help improve water quality by filtering out sediment and contaminants from runoff water entering the pond.

- Q: What are the considerations for geotextile selection in riverbank stabilization?

- There are several important considerations for geotextile selection in riverbank stabilization. Firstly, the geotextile must have sufficient strength and durability to withstand the hydraulic and environmental conditions of the specific riverbank. Additionally, it should have good filtration properties to prevent soil erosion and promote water drainage. The geotextile's permeability and porosity are also crucial factors, as they determine the rate of water flow and allow for proper drainage. Lastly, the geotextile should be compatible with other materials used in the stabilization process and be able to withstand any chemical exposure or biological degradation that may occur in the riverbank environment.

Send your message to us

Geotextile Factory Woven Fabric Anti Mat Groundcover

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords