3003H32 Aluminum Coil 0.05 X 102 - Aluminium Prepainting Polyester Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

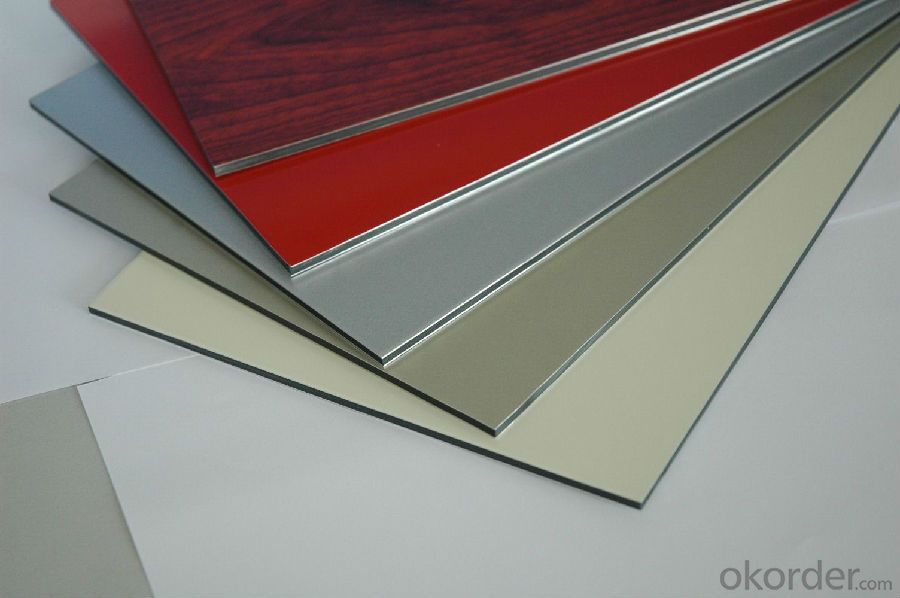

Structure of Aluminium Prepainting Polyester Coated coil:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Prepainting Polyester Coated coil:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

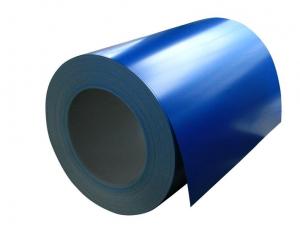

Images of the Aluminium Prepainting Polyester Coated coil:

Aluminium Prepainting Polyester Coated coil Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Prepainting Polyester Coated coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum coils be used in the production of aluminum composite ceilings?

- Yes, aluminum coils can be used in the production of aluminum composite ceilings. Aluminum coils are often used as the base material for manufacturing aluminum composite panels, which are then used to create ceilings. These coils are typically made of high-quality aluminum alloy and have undergone various processes to ensure their strength, durability, and aesthetic appearance. The aluminum coils are coated with a protective layer, such as PVDF or polyester, to enhance their resistance to weathering, UV rays, and corrosion. This coating also allows for a wide range of color options, providing flexibility in design choices for aluminum composite ceilings. Overall, aluminum coils are an essential component in the production of aluminum composite ceilings, offering a lightweight, fire-resistant, and long-lasting solution for various architectural and interior design applications.

- Q: I want to remove melted aluminium piston material from an engine cylinder with burning a hole in the cylinder!

- Aluminum reacts with sodium hydroxide, and will dissolve in a basic solution, while the steel cylinder liner will be unaffected...in theory. This is totally impractical though. You need to machine out the damaged piston, either by boring or grinding the material away.

- Q: What’s the standard of tensile strength and ductility of aluminum coil 3003?

- Detailed description can help resolve problems quickly. Performance and status is a related. As aluminum coil is usually semi-hard, the tensile strength is greater than or equals 150, ductility is greater than or equals 12.

- Q: Is it okay to combine copper with aluminum in case of minting or coin making? Thanks :)

- Well, there are aluminum alloys that have copper in them (although they usually have other metals also), so I don't think it would be a problem. If you're thinking of copper plated aluminum, there is the potential for a galvanic reaction (meaning like a battery cell) that could cause the coin to corrode and fall apart. It's the same problem with the current production of US cents (which are copper coated zinc).

- Q: Can aluminum coils be used in curtain wall systems?

- Yes, aluminum coils can be used in curtain wall systems. Aluminum is a popular material choice for curtain walls due to its lightweight, durable, and corrosion-resistant properties. Aluminum coils can be easily fabricated and formed into the desired shapes and profiles required for curtain wall systems, making them a suitable option for this application.

- Q: How does the alloy composition affect the properties of aluminum coils?

- The alloy composition significantly affects the properties of aluminum coils. Different alloy compositions can alter the coil's strength, corrosion resistance, electrical conductivity, and thermal conductivity. For example, adding elements like copper or magnesium can enhance the coil's strength and improve its ability to withstand high temperatures. On the other hand, alloying elements like silicon or manganese can improve the coil's corrosion resistance. Consequently, the choice of alloy composition is crucial in determining the suitability of aluminum coils for specific applications.

- Q: What is the bending radius for aluminum coils?

- The bending radius of aluminum coils is subject to variation depending on various factors, including the thickness and temper of the aluminum, as well as the specific alloy employed. In general, aluminum coils possess a high level of ductility and malleability, enabling them to be bent to a relatively tight radius in comparison to other materials. Nonetheless, it is crucial to refer to the manufacturer's guidelines or specifications for the particular aluminum coil in use to ascertain the recommended bending radius. Doing so will guarantee that the bending procedure remains within the material's limits, preventing any undesirable deformation or damage.

- Q: What is the maximum coil width available?

- The maximum coil width available varies depending on the specific application and industry. However, it can range from a few inches to several feet, depending on the capabilities of the coil processing equipment and the requirements of the customer.

- Q: How are aluminum coils shipped and transported?

- Aluminum coils tend to be shipped and transported in various ways, depending on factors like size, weight, and destination. Below are a few common techniques: 1. Utilizing flatbed trucks: Flatbed trucks are frequently employed when shipping smaller aluminum coils for shorter distances. These coils are securely loaded onto the flatbed and fastened with straps or chains to prevent any movement during transportation. 2. Opting for intermodal containers: When shipping aluminum coils over longer distances, intermodal containers are a popular choice. These containers can be loaded onto trucks, trains, or ships, providing versatility. The coils are typically stacked and secured within the container using bracing or blocking materials to avoid any shifting. 3. Employing rail transport: Rail transport is also an option for transporting aluminum coils, particularly over longer distances. Coils are loaded onto flatcars or specialized coil cars that have built-in cradles or bolsters to securely hold the coils in place during transit. 4. Utilizing vessels: For international or distant shipments of aluminum coils, sea transport via cargo vessels is often used. Coils are carefully loaded into the cargo hold of the vessel and secured with lashings or other methods to prevent any movement or damage during the voyage. Regardless of the chosen transportation method, it is crucial to ensure that the aluminum coils are adequately protected from moisture, dust, and other potential sources of damage during transit. Packaging materials like moisture-resistant wrapping, protective covers, or crates are employed to safeguard the coils and maintain their quality until they reach their destination.

- Q: Can aluminum coils be used in the production of cryogenic storage tanks?

- Yes, aluminum coils can be used in the production of cryogenic storage tanks. Aluminum is a suitable material for cryogenic applications due to its low density, high thermal conductivity, and excellent corrosion resistance. These properties make it ideal for storing and transporting cryogenic liquids such as liquid nitrogen, oxygen, and argon. Aluminum coils can be used to fabricate the inner shell of the storage tank, providing a lightweight and durable solution. Additionally, aluminum is easily formable, allowing for the creation of complex tank shapes and designs. However, it is important to note that aluminum has a higher coefficient of thermal expansion compared to other materials like stainless steel, so proper design considerations must be taken to accommodate for thermal contraction and expansion during cryogenic operations.

Send your message to us

3003H32 Aluminum Coil 0.05 X 102 - Aluminium Prepainting Polyester Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords