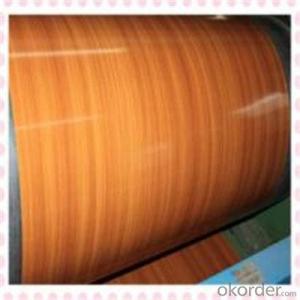

Wood Pattern Coated Galvanized PPGI Steel Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 77 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Glove:

1. Environment friendly

2. Lower cost and maintenance

3. Long using time up to 10 years

4. Fast construction, time saving and labor saving

5. Easy cleaning

6. Antistatic

Festures of Glove:

Building industry | Outdoor application | Roof, structural balcony, panels, window sills, window frames, gates, garage doors, rolling doors, booths, shutters, watch rooms, makeshift houses, street waiting room (booth), refrigerators, etc. |

Indoor application | Room doors, dividing walls, door frames, light house steel structures, sliding doors, screens, ceilings, toilets, interior elevator lobby, stairwayventilating duct, communication pipelines. |

Specifications of Glove:

Surface Treatment | Hop-dipped Galvanized ,coated |

AZ coating | 50-275g/m2 |

Spangle | Normal/Min/Zero |

Minimum order | 25 Metric Tons |

Place of Origin | China(Mainland) |

Packing | Fully Applicable for exporting seaworthy packing of horizontal type on wooden skids |

Price terms | FOB Tianjin, CFR, CIF |

Terms of payment | T/T, L/C or T/T and L/C |

Delivery Detail | within 7-25 days after receiving pre-payment (as per the order quantity) |

Images of Glove:

FAQ:

1.What about the delivery.

We can arrange the shipment about 15-25 days after the deposit.

2.What about payment term?

30% T/T deposit, balance against B/L copy.

Full T/T payment if quantity less than MOQ.

3.How much about MOQ?

Normally 100pcs,but small order is acceptable as well.

- Q: What are the safety precautions to be taken while handling steel coils?

- Some safety precautions to be taken while handling steel coils include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. It is important to use proper lifting techniques and equipment, such as forklifts or cranes, to avoid strains or falls. Coils should be stored on stable surfaces and secured to prevent them from rolling or falling. Additionally, workers should be trained on proper handling procedures and be aware of the potential hazards associated with sharp edges, heavy weight, and unstable loads.

- Q: I just bought some cheap earrings from this beauty supply store but they said surgical steel So will they prevent my ears from bleeding / infection ?

- Surgical steel is a grade of steel often used in medical appliances like tweezers, forceps, etc. It's generally non-reactive and considered very safe. It doesn't contain any special properties against infection--you still have to observe basic hygiene and clean your piercings properly--but most people can wear surgical steel earrings without a problem. However, if you have a contact allergy to base metals like nickel, surgical steel may cause redness or irritation because of the metals used in it. If cheap rings or necklaces make your skin break out in a rash you should NOT wear surgical steel.

- Q: How do steel coils contribute to corrosion resistance in products?

- Corrosion resistance in products is achieved through a combination of factors provided by steel coils. Firstly, the coils are typically constructed from stainless steel, which contains a high concentration of chromium. This chromium forms a passive film on the steel's surface, acting as a protective oxide layer that prevents corrosion. Furthermore, this film possesses the ability to self-heal, regenerating itself if damaged or scratched, thereby ensuring continuous corrosion protection. In addition, the steel coils undergo a process known as galvanization, which involves applying a layer of zinc to the steel's surface. This zinc layer functions as a sacrificial anode, corroding preferentially to the steel. This sacrificial corrosion shields the underlying steel, effectively preventing the formation of rust and other types of corrosion. Moreover, steel coils can be coated with various protective materials like epoxy or polyurethane to enhance their corrosion resistance. These coatings act as an additional physical barrier, preventing moisture, chemicals, and other corrosive elements from reaching the steel surface. Lastly, steel coils can be manufactured with specific alloying elements such as nickel or molybdenum, further enhancing their resistance to corrosion. These alloying elements bolster the strength and durability of the steel, enabling it to withstand harsh and corrosive environments more effectively. In summary, steel coils contribute to the corrosion resistance of products by utilizing stainless steel, galvanization, protective coatings, and alloying elements. The implementation of these measures ensures that products retain their structural integrity and appearance over time, even under demanding and corrosive conditions.

- Q: Im in the process of replacing the gutters/down spouts on my house. The top of the house is four sided. The bottom level has a porch area with 3 sides, two smaller roofs in the back, and one small roof on the side with all stainless steel gutters. A two story house. Not sure of the demensions. They were made at a Steel Mill where the previous owner, worked.This guy wants to buy the stainless gutters but I need to know the market value of this steel and offer him a price. Can someone tell me what I can sell it for? Does it go by the pound? Foot? Can you give me an idea please? Theres a lot of it! I have no clue what to do! Thanks!

- i know it goes buy the pound but i do not know how mutch a pound.waite for some more answers someone must know.or call your local junk yard and ask them.

- Q: What is the average lifespan of a steel coil storage rack?

- The average lifespan of a steel coil storage rack can vary depending on various factors such as the quality of the rack, the frequency and intensity of use, and proper maintenance. However, on average, a well-maintained and properly used steel coil storage rack can last between 10 to 20 years.

- Q: How are steel coils used in the production of steel beams?

- Steel coils are an essential component in the production of steel beams. These coils are typically made by hot rolling steel strips in a continuous process. The coils are then sent to a steel beam manufacturing facility to be further processed. Firstly, the steel coils are uncoiled and flattened to obtain a flat surface. This ensures the uniformity of the beam's dimensions and improves the overall quality. The uncoiling process involves feeding the coil through a series of rollers, which gradually unroll the steel strip. Once the steel strip is uncoiled, it is then cut into specific lengths, depending on the desired size of the steel beams. This cutting process is typically done using automated machines, which ensure precision and accuracy. Next, the cut steel strips are shaped into the desired profile of the steel beams. This is achieved through a process called roll forming, where the steel strip is passed through a series of rollers that gradually bend and shape it into the required shape. The roll forming process can create various types of steel beams, such as I-beams, H-beams, and U-beams, depending on the design and structural requirements. After the roll forming process, the steel beams undergo further finishing operations, such as straightening, welding, and surface treatment. Straightening ensures that the beams are perfectly aligned and free from any deformations. Welding is performed to join different sections of the beams together, ensuring their structural integrity. Lastly, the beams are surface treated, usually through processes like shot blasting or painting, to protect them from corrosion and enhance their appearance. In summary, steel coils play a crucial role in the production of steel beams. They provide the raw material that is uncoiled, cut, shaped, and further processed to create high-quality steel beams. These beams are widely used in various construction projects, ranging from buildings and bridges to industrial structures, making them an essential component in the construction industry.

- Q: What are the common coil loading and unloading techniques?

- The common coil loading and unloading techniques include using cranes or forklifts to lift and move the coils onto trucks or storage racks. Another technique is using coil transfer cars or coil handling equipment to transport the coils within a facility. Additionally, some facilities utilize coil upenders or turnstiles to rotate the coils for easier loading and unloading.

- Q: What are the different methods of edge trimming steel coils?

- Manufacturers have various methods at their disposal for edge trimming steel coils, which are chosen based on their specific preferences and requirements. Some commonly used methods include: 1. Slitting: This method involves passing the coil through rotating circular blades to precisely cut the edges. It is suitable for different thicknesses of steel coils. 2. Milling: By using milling cutters, excess material is removed to achieve the desired edge finish. Milling is often employed for thicker steel coils or when a specific edge profile is needed. 3. Shearing: A sharp blade is used to cut the steel coil along a straight line, providing a clean and straight edge. This method is commonly used for thinner steel coils. 4. Laser cutting: Edge trimming is achieved by utilizing a focused laser beam to melt or vaporize the excess material, resulting in a precise and smooth edge. Laser cutting is often preferred for thinner gauges or when intricate shapes or patterns are necessary. 5. Water jet cutting: This method involves a high-pressure stream of water mixed with abrasive particles to trim the edges of the steel coil. Water jet cutting offers a versatile and precise cutting solution, particularly for thicker steel coils and complex shapes. Manufacturers should carefully assess their specific requirements, including coil thickness, desired edge finish, speed, and cost, to choose the most suitable edge trimming method for their steel coils.

- Q: How are steel coils transported internationally?

- Steel coils are typically transported internationally using various modes of transportation such as ships, rail, and trucks. Ships are commonly used for long-distance transportation, where steel coils are loaded onto specialized vessels equipped with cranes for efficient loading and unloading. Rail and trucks are often used for shorter distances or for transporting steel coils from the port to the final destination. Specialized equipment such as flatbed trailers or intermodal containers are utilized to ensure the safe and secure transport of steel coils.

- Q: Can steel coils be coated with zinc-nickel alloy?

- Yes, steel coils can be coated with a zinc-nickel alloy. Zinc-nickel alloy coating provides excellent corrosion resistance and is commonly used in various industries including automotive, construction, and manufacturing.

Send your message to us

Wood Pattern Coated Galvanized PPGI Steel Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 77 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords