Wood Grain Aluminum Coil Stock - Alloy 1100, 1060, 1200

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

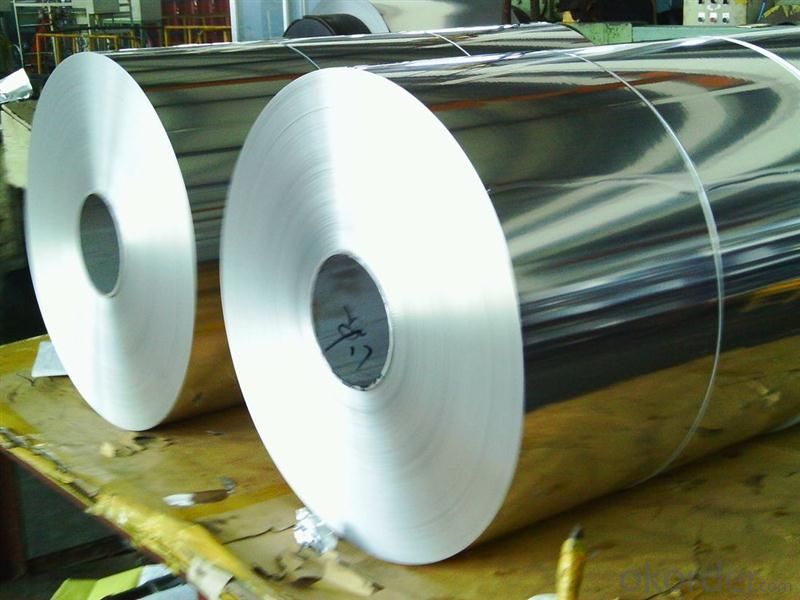

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q: How are aluminum coils used in the production of sporting goods?

- Sporting goods production relies heavily on aluminum coils because of their lightweight, durable, and corrosion-resistant properties. These coils are primarily employed in the manufacture of baseball bats, tennis rackets, golf clubs, and bicycle frames. A major advantage of aluminum coils is their lightweight nature, which allows for improved maneuverability and performance. For example, hollow barrels created using aluminum coils enhance swing speed and power in baseball bats. Similarly, in tennis rackets and golf clubs, aluminum coils are used to construct the shaft, providing players with better control and maneuverability during gameplay. The durability of aluminum coils ensures that sporting goods can endure intense physical activities. Whether it is the impact of a baseball striking a bat or the force exerted on a bicycle frame during a rough ride, aluminum coils offer the necessary strength and resilience to withstand such pressures. This durability is crucial in extending the lifespan of sporting goods, reducing the need for frequent repairs or replacements. Additionally, the corrosion-resistant properties of aluminum make it an ideal material for sporting equipment exposed to various weather conditions or moisture. Aluminum coils are resistant to rust, ensuring that sporting goods can maintain their performance and appearance over time. This quality is particularly advantageous in outdoor sports like golf or cycling, where exposure to rain, humidity, or perspiration is common. In conclusion, the extensive use of aluminum coils in the production of sporting goods is driven by their lightweight, durable, and corrosion-resistant properties. These coils contribute to the overall performance, strength, and longevity of sporting equipment, enhancing the experience of athletes and enthusiasts alike.

- Q: Is it possible to utilize aluminum coils in the construction industry as building materials?

- <p>Yes, aluminum coils can be used for building materials. They are valued for their lightweight, corrosion resistance, and strength. Aluminum coils are commonly used in roofing, siding, window frames, and facades due to their durability and low maintenance requirements. Additionally, they can be easily shaped and recycled, making them an environmentally friendly option in construction.</p>

- Q: What are the different mechanical properties of aluminum coils?

- Aluminum coils are highly sought after for a variety of uses due to their diverse mechanical properties. Some key properties of aluminum coils include: 1. Strong: Aluminum coils are impressively strong, making them suitable for structural purposes. Their strength can be further enhanced through alloying or heat treatment processes. 2. Flexible: Aluminum coils are highly malleable, allowing for easy shaping and forming. This property enables the creation of intricate designs and complex shapes without compromising the integrity of the material. 3. Lightweight: Aluminum is known for its low density, making it one of the lightest metals available. This characteristic makes aluminum coils ideal for industries like aerospace and automotive, where weight reduction is crucial. 4. Resistant to corrosion: Aluminum naturally resists corrosion, forming a protective oxide layer that prevents further oxidation. This quality makes aluminum coils suitable for outdoor and marine environments, as they can withstand harsh conditions and require minimal maintenance. 5. Good conductivity: Aluminum is an excellent conductor of both heat and electricity. This characteristic makes aluminum coils ideal for applications that require efficient heat transfer, such as in heat exchangers and electrical wiring. 6. Easy to machine: Aluminum coils can be easily machined due to their low melting point and the way they form chips. This characteristic allows for high-speed machining operations, resulting in reduced production time and costs. 7. Weldable: Aluminum coils can be easily welded using various techniques, such as TIG or MIG welding. This characteristic enables the fabrication of complex structures and the joining of aluminum components. 8. Resistant to fatigue: Aluminum exhibits excellent fatigue resistance, allowing it to withstand repeated stress cycles without failure. This quality makes aluminum coils suitable for applications subjected to cyclic loading, such as automotive components or structures exposed to wind or waves. Overall, the combination of unique mechanical properties possessed by aluminum coils, including strength, flexibility, lightweight, corrosion resistance, conductivity, machinability, weldability, and fatigue resistance, makes them a versatile material choice for a wide range of industries and applications.

- Q: How do aluminum coils perform in applications where high strength is required?

- Aluminum coils are renowned for their outstanding performance in situations that demand strong materials. Despite being lightweight, aluminum possesses impressive strength characteristics, making it an ideal option for numerous industries. The alloy composition of aluminum coils is a key contributor to their exceptional strength. By incorporating elements like copper, magnesium, and zinc, aluminum alloys can be customized to enhance their strength. These alloying elements create intermetallic compounds that significantly boost the aluminum's strength without compromising its weight. Moreover, various manufacturing processes, such as hot or cold rolling, further enhance the strength of aluminum coils. These processes align the metal's grain structure, resulting in increased strength and resistance to deformation. As a result, aluminum coils can endure high levels of stress, making them suitable for applications that prioritize durability and reliability. Furthermore, aluminum coils display exceptional resistance to corrosion, which further enhances their performance in high-strength applications. Aluminum naturally forms a protective oxide layer on its surface, safeguarding it against corrosion and ensuring long-lasting durability. This corrosion resistance is particularly valuable in environments where high-strength materials are exposed to moisture, chemicals, or harsh weather conditions. Additionally, aluminum coils possess excellent thermal conductivity, enabling efficient heat dissipation in applications like heat exchangers or radiators. This property is crucial in industries that require high-strength materials to withstand elevated temperatures, as it helps prevent overheating and subsequent material degradation. In summary, aluminum coils are highly effective in high-strength applications due to their alloy composition, manufacturing processes, corrosion resistance, and thermal conductivity. Their combination of strength, lightweight design, and durability makes them a preferred choice in industries ranging from automotive and aerospace to construction and electrical.

- Q: how many chloride ions are present? how many chlorine ions are present? what is the mass in grams of one formula unit of aluminum chloride?

- Aluminum Chloride is simply AlCl3 So In each mole of AlCl3 there are 1 mol of Al 3 mol of Cl We know (from periodic table), 1 mol of Al weighs 26.98 g 1 mol of Cl weighs 35.47g so 1 mol of AlCl3 weighs 26.98g + 3x35.47g = 133.39 g sooo moles of AlCl3 = 37.2 g /133.39 g/mol = 0.279 mol in one mol of anything, there are 6.02 x 10 ^ 23 of that thing... so we have 0.279 mol x 6.02 x 10 ^ 23 molecules /mole = 1.68 x 10 ^ 23 And, we know one molecule of AlCl3 dissociates into one Al ion and 3 Cl ions sooo 1.68 x 10 ^ 23 AlCl3 ions dissociate into 1.68 x 10 ^ 23 Al ions so answer is 1.68 x 10 ^ 23 Al ions

- Q: This question asks about the common applications of aluminum coil in everyday life.

- <p>Aluminum coil is widely used in daily life due to its lightweight, corrosion resistance, and thermal conductivity. It's commonly used in construction for roofing and siding, in the automotive industry for car parts, and in the packaging industry for food and beverage cans. It's also used in electrical applications like transformers and wiring due to its good conductivity. In the kitchen, aluminum foil is used for cooking and food storage, and in the HVAC industry for heat exchangers and ductwork. Its versatility makes aluminum coil an essential material in many industries and everyday applications.</p>

- Q: What is the maximum width and thickness of aluminum coils?

- The maximum width and thickness of aluminum coils vary depending on the specific grade and manufacturing capabilities. However, as a general guideline, aluminum coils can range in width from a few inches to several feet, while thickness can range from a few millimeters to several inches. It is important to consult the manufacturer or supplier for precise specifications based on the intended application.

- Q: When you open an aluminum beverage can, do particles of aluminum get into the drink?

- No. Aluminum has metallic bonds, so atoms don't break off that easily.

- Q: I am writing a science-fiction story, and I am planning on making Aluminum this ultra-valuable element (Which adds irony - Aluminum is the third most abundant element on Earth!) Even if ol' atomic no. 13 is as common throughout the universe as it is on Earth, I can bring up 'multiverse' to get away with it. I think it'd still be nice to know.

- Interesting, the aluminum must flow? Aluminum is not as common as other elements. It is not readily produced in the cores of stars through the alpha-capture process (which produces things like carbon, oxygen, neon, magnesium, silicon, etc.). This means it is only produced via supernova explosions. The table in Wikipedia (see link below) will give you an idea of the relative abundance to other elements. (Notice that magnesium and silicon, which are before and after aluminum, are nearly 100 times more abundant). As a fellow, Sci-Fi enthusiast, I'd remind you to make you're story believable. If you decide that your universe won't have supernovae, remember that would mean there would be no iron, gold, uranium, etc. My answer has been long enough, but I'm sure you have an idea why aluminum is so abundant on the Earth's crust so I'll stop here.

- Q: Are there any fire safety considerations when using aluminum coils?

- When using aluminum coils, fire safety considerations must be taken into account. This is because aluminum is a highly flammable material, and if not handled and installed correctly, it can present a fire hazard. To minimize the risk of fire, it is crucial to install the aluminum coils in a manner that reduces the chance of fire, such as using appropriate insulation and avoiding direct contact with other flammable substances. Furthermore, regular maintenance and inspections should be conducted to detect any potential problems or signs of overheating that may result in a fire. Adhering to fire safety protocols and guidelines, like having a fire extinguisher nearby and ensuring adequate ventilation, can also assist in mitigating the fire risk associated with aluminum coils.

Send your message to us

Wood Grain Aluminum Coil Stock - Alloy 1100, 1060, 1200

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords