Wood Plastic Composite / WPC Board / wpc decking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical addatives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

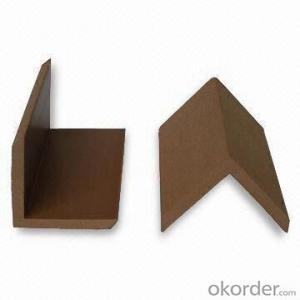

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q: Such as title. Best to be detailed.

- At present, China's PVC flooring production is in a period of development, especially PVC sheet flooring (stone floor) production of domestic technology has been very mature, the country has a lot of well-known brands, production technology and quality are relatively high, many brands out Many foreign PVC floor manufacturers also set up factories in China, especially in South Korea, there are many manufacturers set up factories in China to produce. Some of the big brands of manufacturers will also own sheet flooring production line to China for production, and then sold back to the rest of the world. PVC flooring production technology alone is not yet mature, can only make a fake article, some key technology domestic floor manufacturers can only rely on imports, the product still has serious flaws, although there are foreign brands of manufacturers in China set up production , But the key technology is produced in foreign countries. If you want to introduce PVC flooring production line, I suggest you or the introduction of coil flooring production line as well. Because our country's PVC sheet flooring demand is very large, especially in the low-end PVC coil flooring market is very large. I am glad to answer the question of the landlord if any mistakes please forgive me

- Q: I dont think they are sealed as they scratch really fast. What can I use thats safe/cleans/polishes the shine back to my dull floors? Floors were installed when we moved about 2 years ago. Thanks

- Do you mean laminate floors? If so, these links will give you the information you need.

- Q: Nature, icon, peace of mind floor, these three kinds of solid wood and composite purchase price each? Thank you more

- These brands at that time I also looked at the last choice of peace of mind some people feel good just to see more in the ad above, but the price is not so people can feel satisfied. If it is to change the wood floor, then you can look at the peace of mind, my family is now using this brand of solid wood flooring, and now there are four years fast, did not appear what the problem of cracking, and peace of mind after-sales service Also feel comfortable, interested, then may wish to refer to the next.

- Q: This question is also under remodeling.I'm considering installing Thomasville's Walnut engineered flooring, or solid Bamboo flooring from home depot throughout my upstairs. I would appreciate hearing from anyone that has installed either of these products.Specifically, do either of these floors dent and scratch easily? I have three cats, two children and my massage business in my home.Does one of these outshine the other? Does either hold up as well as any other product you might have experienced? Do you know of anyone who has used these? They are similar in price, so that is not a factor. Thanks and I look forward to input anyone can provide!Additional details: It looks like all the interlocking floors come pre-finished. All the others I'd have to stain and poly myself, correct? Since I don't build homes, I'm going for a balance between easy install and quality. Thanks!

- The bamboo is hard to indent but scratches rather easily. It being so hard, it doesn't take finish well. Also, almost any flooring you buy from Home Depot is going to be of a lesser quality that what you would find at a retailer. That's how they stay in business. The walnut should give you many years of life without any problems. It too is hard, but has a more open grain to accept the finish. Mannington makes a nice engineered walnut. Not sure of the series, but you can find it easily on their website. Hope this helps. Clyde

- Q: Composite wood flooring

- Composite wood flooring with solid wood flooring and laminate flooring, solid wood flooring is divided into three layers of solid wood flooring and multi-layer parquet.

- Q: How many pieces of composite flooring?

- Ordinary routines are in 20!

- Q: The composite floor is a good reason to use a straight pavement or a keel

- The ground leveling; remember to stay the thickness, usually about 1.7, and then paved before the clean-up, the ground clean up, put the floor under the moisture-proof pad, tasting taste of enlightenment to Germany to avoid the spring glass do not take tin foil, airtight is also easy to distribute heavy metals , The general composite flooring are straight shop, that is, do not play keel, do not fight nails, if the keel is more trouble, disassembly is also troublesome. Buy the floor, to build nest building materials to see home, Sihetadi floor style, affordable. The main products of home building materials are purchased directly from many of the top manufacturers of developed countries such as Germany, Italy, Netherlands, Belgium, Spain, France, USA, Japan and Korea. Domestic products are also from the international standards of export-oriented enterprises direct procurement. All product quality is in line with the European Union, the United States, China or other world-class international certification standards. Nest a professional international procurement team, each year around the world of professional building materials home exhibition, visit thousands of professional manufacturers, carefully selected for each product.

- Q: Home new house to buy a composite floor, the floor is also good, but the manufacturers call the floor paved, will be free to send a floor maintenance, is to brush a layer of floor to protect the floor of the essential oils. They did not want them to do maintenance, but they gave me to do ideological work, have to protect the floor to the floor with a layer of essential oil, but the oil is now as long as a piece of the floor on a piece, and very ugly, but let The effect of the floor worse, and now want to get off this layer of the floor of the oil, the top of the dumplings of the dumplings Lengong Chuanchuan Long how to get it? Do not know what to remove these oils? The The Regret it, the composite floor itself does not need to maintain, to maintain directly to buy real floor. More

- The friend, from the industry, the so-called protection of essential oils is just to place the joints, with wax to fill it, really good floor is not needed, the middle of the U-slot you have to look at the seam will not Will be great, if the big words, it is recommended to call manufacturers to replace, if not, it is recommended that wax is essential oil it, if the top of the top of the dumplings of the dumplings Lengong pass you want to get rid of the most simple way is to buy a small bottle Erguotou down with a cloth made of cotton, so you can go to the wax, do not hurt the floor, I hope my method is useful to you, may you have a happy and happy home

- Q: To see what is the mouth of the floor, and as the world floor, all the smart lock, do not have to.

- Environmental quality Qualified laminate flooring is mainly reflected in two aspects. First, strengthen the wood floor product performance indicators to meet the GB / T national standards. Second, environmental indicators must meet GB-2001 national standards. Environmental protection index refers to whether the formaldehyde emission of the laminate flooring meets the requirements of the national standard GB-2001. For the strengthening of wood flooring, the formaldehyde emission GB-2001 standard: E1 level ≤ 1.5mg / L. In line with the E1 level of the floor can be used directly to the interior, the people can rest assured to buy and rest assured to use. There are many ways to check the environmental quality of the floor. At present, the method of testing the laminate flooring is usually tested according to the dryer method according to the GB-2001 standard. But the arbitration of controversial products, to use the GB-2001 standard in the climate box method for testing life home is one of the brand, so the quality and environmental protection should be good.

- Q: If you want to shop on the original floor with laminated flooring what needs attention?

- 1, the original floor is a tile or composite floor, if the tile can be directly shop, but in the kitchen and bathroom joints to seal, to prevent moisture into. 2, if it is on the floor and then shop, to ensure that the original floor smooth, dry, because a number of the bottom floor deformation, the upper floor will be deformed. At the same time also consider the floor increased, the door should be shortened, the composite floor and the original tile floor of the convergence problem. (1) Solid wood floor flatness: If it is very narrow old wooden solid wood flooring, if there is uneven treatment. Such as loose, fixed firmly; if it is Alice, you can planing. Or simply remove one or two pieces, because the smaller area, does not affect the composite floor pavement. If it is wide board, to plan to deal with good. (2) check whether the sound of solid wood flooring, what causes, loose keel or loose floor. (3) keel integrity. Check the keel is loose, there is loose, to re-reinforcement; check whether there is rot, if the decay of aging, replace the new keel. Because the joint effect, if the keel is not good, will have a new composite floor impact. (4) all with more than a few years of solid wood flooring, in the floor before the composite floor, it is best to use the United States solid nail keel reinforcement.

Send your message to us

Wood Plastic Composite / WPC Board / wpc decking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches