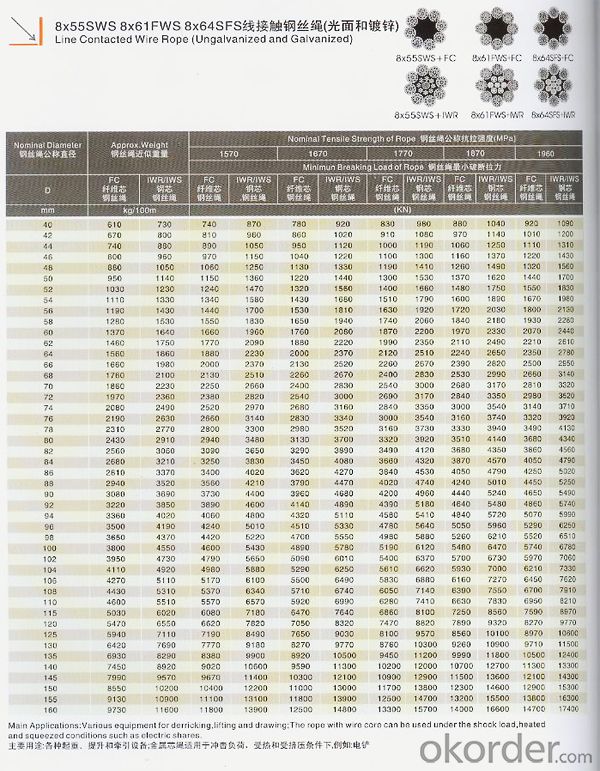

LINEAR CONTACT LAY WIRE ROPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: How are steel products used in the construction industry?

- Steel products are commonly used in the construction industry for various purposes, such as structural framing, reinforcing concrete, and creating durable infrastructure. They provide strength, stability, and flexibility in building designs, allowing for the construction of high-rise buildings, bridges, and other large structures. Steel products are also used for roofing, siding, and cladding due to their resistance against corrosion and extreme weather conditions. Additionally, steel is often employed in the construction of industrial facilities and manufacturing plants, thanks to its ability to support heavy machinery and equipment. Overall, steel products play a vital role in modern construction, ensuring safety, durability, and versatility in various building projects.

- Q: What are the uses of steel in the construction of schools and universities?

- Steel is commonly used in the construction of schools and universities due to its superior strength, durability, and versatility. It is used to create the framework and structural components of buildings, providing stability and support. Steel beams and columns can withstand heavy loads, allowing for larger open spaces and flexible floor plans. Additionally, steel is fire-resistant, which enhances the safety of educational facilities. Its use in construction also ensures faster construction times and cost-effectiveness, making it an ideal material for schools and universities.

- Q: What are the different types of steel fasteners and their uses in the marine industry?

- There are several types of steel fasteners commonly used in the marine industry. Some of the most common ones include stainless steel bolts, screws, and nuts. These fasteners are highly resistant to corrosion, making them ideal for use in marine environments where they are exposed to saltwater and moisture. They are often used to secure various components of a boat or ship, such as railings, cleats, and fittings. Additionally, steel fasteners like snap hooks and shackles are used to connect ropes and chains, providing reliable and secure connections in the marine industry.

- Q: How are steel products used in the chemical industry?

- Steel products are widely used in the chemical industry due to their durability, resistance to corrosion, and ability to withstand high temperatures and pressures. They are commonly used in the construction of chemical processing equipment such as tanks, pipelines, reactors, and storage vessels. Steel products also play a vital role in supporting and securing various chemical processes, ensuring the safe and efficient production of chemicals.

- Q: How are steel products used in the manufacturing of consumer goods?

- Steel products are used in the manufacturing of consumer goods in various ways, such as in the production of appliances like refrigerators, washing machines, and ovens, as well as in the construction of automobiles, bicycles, and furniture. Steel's durability, strength, and versatility make it an ideal material for these applications, providing stability, safety, and longevity to the final products.

- Q: What are the different types of steel coils and their uses?

- There are several types of steel coils, including hot-rolled, cold-rolled, galvanized, and stainless steel coils. Hot-rolled coils are used for applications requiring high strength and durability, such as automotive parts and construction materials. Cold-rolled coils are used for precision applications where a smooth and polished surface is required, such as in appliances and metal furniture. Galvanized coils are coated with a layer of zinc to prevent corrosion, making them suitable for outdoor structures and roofing. Stainless steel coils are highly resistant to corrosion and are used in various industries, including food processing, chemical processing, and medical equipment manufacturing.

- Q: What are the different types of steel profiles and their applications?

- There are several different types of steel profiles, each with their own specific applications. Some common types include I-beams, which are used in construction for structural support; C-channels, which are often used in industrial applications for framing and support; angle profiles, which are used for corner reinforcement and bracing; and flat bars, which are commonly used in manufacturing and construction for support and framing. Other types of steel profiles include round bars, square bars, and T-sections, each with their own unique applications in various industries.

- Q: What are the properties of corrosion-resistant steel for marine applications?

- Corrosion-resistant steel for marine applications possesses properties such as high levels of chromium and nickel, which provide excellent resistance to corrosion caused by saltwater exposure. It also has a protective oxide layer that forms on the surface, preventing further oxidation. Additionally, it exhibits high strength and durability, making it ideal for withstanding harsh marine environments.

- Q: What is the role of steel in the telecommunications industry?

- Steel plays a crucial role in the telecommunications industry as it is used to construct transmission towers and other supporting structures. These steel structures provide the necessary height and stability for antennas and other equipment to transmit and receive signals. Steel's strength, durability, and ability to withstand harsh weather conditions make it an ideal material for telecom infrastructure, ensuring reliable and efficient communication networks.

- Q: What are the uses of steel gratings?

- Steel gratings have a wide range of uses, including serving as industrial flooring for platforms, walkways, and staircases, providing ventilation and drainage in areas such as sewage treatment plants and chemical plants, acting as safety barriers or fencing, and supporting heavy loads in construction projects.

Send your message to us

LINEAR CONTACT LAY WIRE ROPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords