Wholesale Mill Finish Aluminum Roof Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Alloy | AA1100, AA3003, AA3005, AA3105, AA8011 |

Temper | H16-18, H46 |

Thickness | 0.15mm – 1.0mm |

Width | 900mm – 1600mm |

Length | 200m – 2000m |

Chemical Composition (WT %)

| Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Others | Rem. Al |

AA1100 | 0.116 | 0.478 | 0.069 | / | / | / | / | / | / | / | 99.70 |

AA3003 H16-18 | 0.59 | 0.66 | 0.01 | 0.32 | 0.21 | Tr | Tr | Tr | 0.02 | Tr | 98.15 |

AA3003 H46 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | / | / | / | 0.10 | / | 0.20 | 97.02 |

AA3005 | 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.2-0.6 | 0.10 | / | 0.25 | 0.10 | 0.20 | 96.10 |

AA3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.20 | / | 0.40 | 0.10 | 0.20 | 96.45 |

AA8011 | 0.5-0.9 | 0.6-1.0 | 0.10 | 0.20 | 0.05 | 0.05 | / | 0.10 | 0.08 | 0.20 | 97.72 |

Mechanical Properties

| 0.2% Proof stress (Kg/Sqmm) | Ultimate tensile strength (MPa) | % Elongation | Bend test (180 Degree) | % Earing | Depth height (mm) |

AA1100 H16-18 | NA | 150-180 | 2.00 | NA | NA | NA |

AA3003 H16-18 | NA | 178.4 | 3.00 | NA | NA | NA |

AA3003 H46 | 165-205 | >145 | ≥1 | NA | NA | NA |

AA3005 H46 | NA | 195-250 | >180 | > 2 | NA | NA |

AA3105 H46 | 175-225 | >145 | ≥1 | NA | NA | NA |

AA8011 H16-18 | NA | 145-180 | 1.00 | NA | NA | NA |

Embossed color coatedaluminum coil

the company can produce the aluminum coil pattern are: classic orange peel pattern,and variation orange peel pattern (also called as bugs’ pattern). Thicknessspecification is 0.2mm ~ 0.6mm, width less than 1600mm. The materials used arefluorocarbon coated aluminum, polyester coated aluminum coil, aluminum roll,light aluminum, brushed aluminum rolls.

By embossing the surface of aluminum coil elegant, streamlined good, solidsense. Embossed aluminum coil aluminum coil can not only increase the thicknessof the aluminum coil thickness of 0.1 ~ 0.25mm. At the same time can enhance thestrength of aluminum coil, stiffness, and does not affect the original surfacelayer of the aluminum coil with the performance.

Embossed aluminum coil, wide range of uses. Mainly used for indoor and outdoordecoration, freezer, refrigerator, decorative aluminum products, bags, centralair conditioning and ventilation nozzles, and mechanical equipment enclosuresand so on. Is a new decorative material.

Thecompany has two production lines embossed aluminum coil: one for the simpleformula: put through Unwinder mechanical embossing roll winder windingembossed, convenient and quick. Another is the compound: that is embosseddirectly into the device placed in the coating line, coating and embossingsynchronization, when the coating needs of embossed aluminum coil, through thehydraulic transmission, the embossing machine, under the pressure rollerengagement, aluminum coating line directly in the embossing roll, fast, lowcost, no turnover.

Thickness range

0.2mm—0.6mm

Width range

800mm—1590mm

Technical parameters

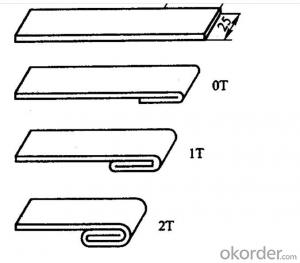

Aluminum thickness | Coating thickness | MEK | T-bend | Impact | Adhesion | Pencil hardness | Boiling water proof |

0.20-0.60mm | ≥18±1um | ≥100times | ≤3T | 50kg.cm | 0grade | ≥HB | no change within 2 hours |

Performance and Application

Embossed aluminum coil for roofing is coatedwith high-performance polyester paints. And its each performance index is up toor exceeds the national standard. With its glorious colors, little chromatism,strong impact and easy machinability, the product serves as a premium materialin roofing, electric appliances, etc.

- Q: Are aluminum coils suitable for lightweight applications?

- Aluminum coils are well-suited for lightweight applications due to their advantageous properties and lightweight nature. With a density about one-third that of steel, aluminum is a lightweight metal that is ideal for prioritizing weight reduction. In various industries such as aerospace, automotive, electronics, and packaging, aluminum coils are commonly used for their excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. Moreover, they offer versatility in design and manufacturing as they can be easily formed, welded, and machined.

- Q: Why do we need aluminum when cooking in the oven at all.

- Keeps the top from getting over cooked and the foil keeps the steam in so your food with be moist.

- Q: Are aluminum coils suitable for reflective insulation?

- Yes, aluminum coils are suitable for reflective insulation. Aluminum is highly reflective and has low emissivity, which means it can effectively reflect radiant heat. This makes it an ideal material for reflective insulation, as it helps to reduce heat transfer by reflecting radiant energy away from the insulated space. Aluminum coils are commonly used in reflective insulation products such as foil-faced insulation boards and radiant barriers.

- Q: Are aluminum coils suitable for marine applications?

- Yes, aluminum coils are suitable for marine applications. Aluminum is a corrosion-resistant material, making it an excellent choice for use in marine environments where exposure to saltwater and other corrosive elements is common. Aluminum coils are lightweight, durable, and have high strength-to-weight ratio, which is important for marine applications where weight reduction is desired. Additionally, aluminum coils can withstand extreme temperatures and have good thermal conductivity, making them suitable for various marine heating and cooling systems. Overall, aluminum coils are a popular choice in marine applications due to their corrosion resistance, durability, and lightweight properties.

- Q: Can aluminum coils be coated with protective films?

- Yes, aluminum coils can be coated with protective films. These films provide a layer of protection against scratches, corrosion, and other damage, helping to prolong the lifespan and enhance the appearance of the aluminum coils.

- Q: How do aluminum coils perform in coastal areas with high salt content?

- Aluminum coils perform relatively well in coastal areas with high salt content due to their inherent corrosion resistance. Aluminum has a natural oxide layer that forms on its surface, providing a protective barrier against saltwater and preventing corrosion. This oxide layer is highly resistant to salt-induced corrosion, making aluminum coils suitable for coastal environments. However, it is important to note that saltwater can still have some corrosive effects on aluminum over time, especially in areas with constant exposure to salt spray and high humidity. To enhance the performance and longevity of aluminum coils in such coastal areas, additional protective measures can be taken, such as applying specialized coatings or utilizing alloys with higher corrosion resistance. Regular maintenance and cleaning of the coils are also essential to remove any salt deposits that may accumulate on the surface. This can be done by rinsing the coils with fresh water periodically to remove salt residue. Additionally, avoiding the use of abrasive cleaners or harsh chemicals is crucial to prevent any damage to the protective oxide layer. Overall, while aluminum coils offer good resistance to saltwater corrosion, proper care and maintenance are still necessary to ensure optimal performance and prolong their lifespan in coastal areas with high salt content.

- Q: I am confused by that. One guy told me that he puts aluminium foil on his modem to receive the Internet better. Another guy told me that aluminium stops all kind of rays. What is correct?

- to improve WiFi signals. But it just acts like a reflector. In other words it increases the signal in one direction and reduces it in another. Another guy told me that aluminium stops all kind of rays. It reflects some kinds of waves. It does not reflect or stop high energy stuff like X-rays and gamma rays.

- Q: Calculate the specific heat of aluminum (in calories).mass of aluminum25.0 gmass of water23.2ginitial temperature of aluminum98.0Cinitial temperature of water20.0Cfinal temperature of water33.0Cround to three decimal places, do not include units.

- Heat gained by water = heat lost by aluminum Heat = H mass = m specific heat =c change in temperature = dT H = mcdT mcdT for water = mcdT for Al (23.2)(1.00)(13) = (25.0)(c(Al))(33-98) c(Al) = (23.2)(1.00)(13)/(25.0)(65) = 0.186 This value is just a bit below the known value of specific heat for aluminum, where c = 0.217 cal/g.C

- Q: How are aluminum coils used in the production of battery enclosures?

- Aluminum coils are used in the production of battery enclosures as they provide a lightweight and durable material that can be easily molded and shaped to form the enclosure. The coils are typically processed and formed into specific shapes using a combination of heating, rolling, and cutting techniques. This allows for the creation of seamless and tightly sealed enclosures that can protect the batteries from external elements and provide efficient heat dissipation.

Send your message to us

Wholesale Mill Finish Aluminum Roof Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords