Mill Finished Aluminum Coil - Home Depot Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished Aluminium Sheet With Prime Quality Description

Mill Finished Aluminium Sheet With Prime Quality is one semi-finished aluminium material. This sheet can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Aluminium Sheet With Prime Quality

Mill Finished Aluminium Sheet With Prime Quality | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Aluminium Sheet With Prime Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Aluminium Sheet With Prime Quality

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Aluminium Sheet With Prime Quality

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

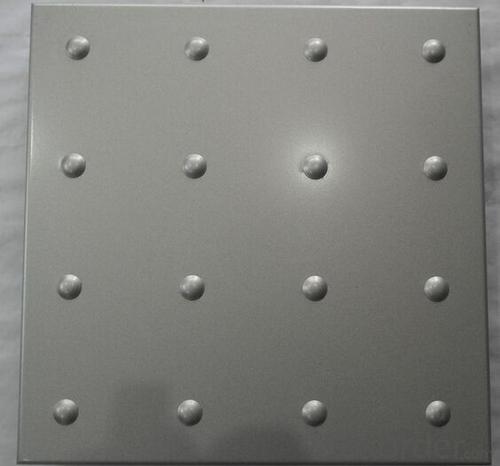

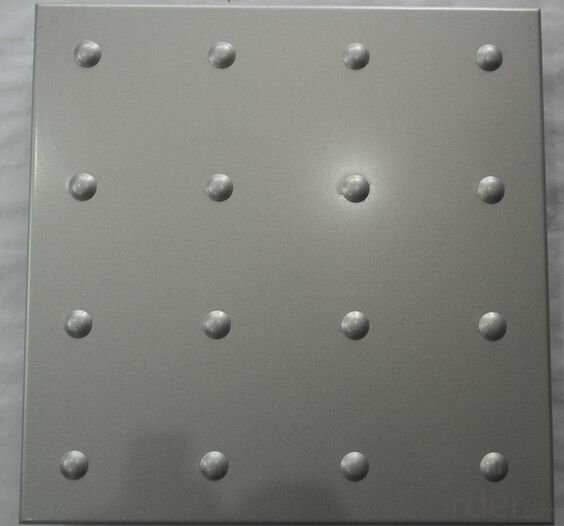

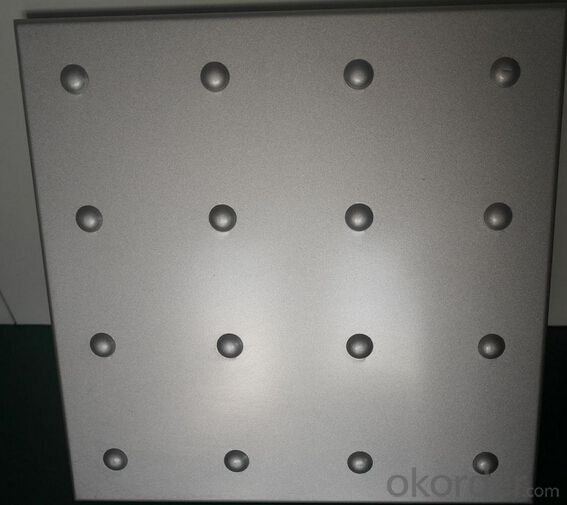

6. Image of Mill Finished Aluminium Sheet With Prime Quality

7. Package and shipping of Mill Finished Aluminium Sheet With Prime Quality

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the shelf life of aluminum coils?

- The shelf life of aluminum coils may differ based on a variety of factors, such as storage conditions, handling, and the specific alloy employed. Provided they are stored correctly, aluminum coils can generally remain usable for several years. To maintain their longevity, it is advisable to store them in a dry and clean environment, keeping them away from moisture, extreme temperatures, and corrosive substances. Moreover, one should handle them with caution to avoid any harm or contamination that might decrease their shelf life. It is also crucial to carry out regular inspections and maintenance to ensure the integrity and endurance of the aluminum coils. Ultimately, for more accurate information regarding the specific shelf life of aluminum coils, it is recommended to refer to the manufacturer's guidelines or consult a professional in the industry.

- Q: Are aluminum coils suitable for pharmaceutical packaging?

- Yes, aluminum coils are suitable for pharmaceutical packaging. Aluminum is a widely used material in the pharmaceutical industry due to its excellent barrier properties, durability, and flexibility. It provides effective protection against moisture, light, oxygen, and other external factors that can degrade the quality and stability of pharmaceutical products. Aluminum coils can be easily formed into various shapes and sizes, making them ideal for packaging different types of pharmaceutical products such as tablets, capsules, and ampoules. The ability to customize the packaging according to specific requirements ensures that the products are properly sealed and protected during storage and transportation. Furthermore, aluminum is non-toxic and chemically inert, meaning it does not react with the contents of the packaging. This is crucial for pharmaceutical products as it ensures the integrity and safety of the medication. Aluminum coils also have excellent heat conductivity, making them suitable for heat-sealing processes commonly used in pharmaceutical packaging. In addition to its functional properties, aluminum is a sustainable and environmentally friendly choice for pharmaceutical packaging. It is easily recyclable, reducing the environmental impact and promoting sustainability in the healthcare industry. Overall, aluminum coils are highly suitable for pharmaceutical packaging due to their barrier properties, flexibility, customization options, non-reactivity, heat conductivity, and sustainability.

- Q: What is an aluminum coil and what is it used for?

- An aluminum coil is a long, flat, and thin sheet of aluminum that is rolled up into a coil shape. It is typically made from high-quality aluminum alloys that are durable, lightweight, and corrosion-resistant. Aluminum coils have a wide range of applications across various industries. One of the most common uses is in the manufacturing of aluminum products, such as cans, containers, and packaging materials. The flexibility and malleability of aluminum coils make them ideal for shaping into different forms and sizes. Additionally, aluminum coils are extensively used in the construction industry for various purposes. They are commonly used for roofing, siding, gutters, and other exterior applications due to their ability to withstand harsh weather conditions and resist corrosion. The lightweight nature of aluminum coils makes them easier to handle and install, reducing labor and transportation costs. Moreover, aluminum coils are also used in heating, ventilation, and air conditioning (HVAC) systems. They are utilized in the production of condenser and evaporator coils, which are crucial components for controlling temperature and humidity in residential, commercial, and industrial buildings. In summary, an aluminum coil is a versatile and valuable material that finds widespread use in numerous industries. Its lightweight, corrosion-resistant, and malleable properties make it an excellent choice for manufacturing aluminum products, as well as for construction and HVAC applications.

- Q: im looking for a bat but i dont know what to get wood or aluminum what is harder wood or aluminum ?? what would be better for hitting hard balls with ( or maybe people ) haha no im joking i need help !!!!

- aluminum is, and hardness isnt everything.. theres bat speed, vibration differences after the swing, wider sweet spots, and durability. aluminum bats dominate wood bats in all these catergories

- Q: Are aluminum coils resistant to mold and mildew?

- Generally, aluminum coils have resistance to mold and mildew. Unlike materials like wood or fabric, aluminum is non-porous and does not absorb moisture. This characteristic reduces its susceptibility to mold and mildew growth. Moreover, protective finishes are often applied to aluminum coils, enhancing their resistance to mold and mildew. Nevertheless, it is important to remember that although aluminum coils are less prone to mold and mildew, they are not entirely immune. If exposed to excessive moisture or humidity, mold and mildew can still develop. Thus, regular cleaning and maintenance are essential to prevent potential mold or mildew growth.

- Q: What is the typical tensile strength of aluminum coils?

- The typical tensile strength of aluminum coils can vary depending on the specific grade and temper of the aluminum being used. Generally, aluminum coils have a tensile strength ranging from 30,000 to 75,000 pounds per square inch (psi). However, it is important to note that this range can be narrower or wider depending on the intended application and the specific alloy being used. Additionally, factors such as the thickness and width of the coil may also impact the tensile strength.

- Q: How do aluminum coils withstand extreme weather conditions?

- Aluminum coils are designed to withstand extreme weather conditions due to their inherent properties and construction. The aluminum used in these coils is highly resistant to corrosion, allowing them to endure exposure to moisture, rain, snow, and even saltwater without deteriorating. Additionally, aluminum coils have excellent heat transfer capabilities, enabling them to dissipate excessive heat and prevent damage from high temperatures. Moreover, they are sturdy and durable, enabling them to withstand strong winds, heavy storms, and even hail. Overall, the combination of corrosion resistance, heat transfer efficiency, and robust construction make aluminum coils well-equipped to endure harsh weather conditions.

- Q: What are the weight and length specifications of aluminum coils?

- The weight and length specifications of aluminum coils can vary depending on the specific application and industry requirements. However, typically aluminum coils can range in weight from a few hundred pounds to several thousand pounds, and in length from a few feet to hundreds of feet.

- Q: Are aluminum coils suitable for electrical insulation?

- Aluminum coils, unfortunately, do not possess the right qualities for electrical insulation. As a result of its conductivity, aluminum facilitates the passage of electric current rather than impeding it. When it comes to electrical systems, the presence of insulation becomes indispensable in order to impede the flow of electricity and provide protection against short circuits or electrical shocks. To achieve this, materials like rubber, plastic, or ceramic are commonly employed due to their remarkable resistance to electric current.

- Q: Are aluminum coils more expensive than other coil materials?

- Yes, aluminum coils are generally more expensive than other coil materials. This is mainly due to the higher cost of producing aluminum compared to other metals, such as copper or steel. Additionally, aluminum coils are known for their superior corrosion resistance, lightweight nature, and high thermal conductivity, which further contribute to their higher price point. However, it's worth noting that the cost can vary depending on factors such as the thickness, size, and specific application of the coil.

Send your message to us

Mill Finished Aluminum Coil - Home Depot Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords