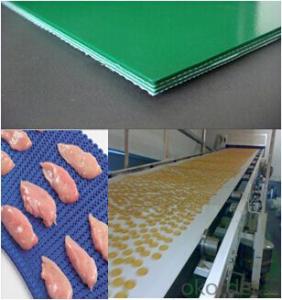

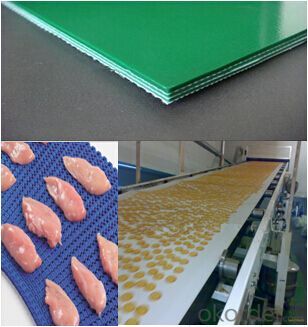

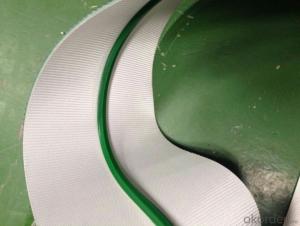

3.0mm PVC Green Conveyor Belt for Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3.0mm PVC Green Conveyor Belt for Light Industry

Specifications

Anti-static and tearing resistant

Abrasion and oil/heat/fire resistant

Working temperature ranges from -10 to 80Deg.C

With advanced coating machine and other excellent facilities, we are professionally producing PVC&PU light conveyor belts, which are extremely suitable for light industry such as beer industry, paper making industry, food industry, textile industry etc.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

* Working temperature ranges from -10 to 80Deg.C

Product pictures:

- Q: How can I remove the rubber flavor on rubber products? It smells terrible

- This odor is stubborn, more difficult to solve in a short timeThe peculiar smell of a small rubber component in my car used for a week before cleaning it. If the price is not high, I suggest you change it.

- Q: Why is rubber resistant to compression and wear better than metal?

- The rubber bushing is made of metal and has a flexible connection. The sheath is made of rubber

- Q: Will the rubber ring of the thermos bottle be harmful to the human body?

- No harmThe rubber washer of the thermos bottle comprises a common thermos bottle, an air pressure thermos bottle, an electric pressure bottle and an automatic electrothermal thermos bottle, etc. the rubber sealing washer is directly contacted with the drinking water, and is sealed and heat insulated

- Q: What kind of rubber products are expensive?

- Rubber products are expensive and the cost of rubber is naturally high, so it can be analyzed from the following points:1, the raw material, choose what kind of natural rubber, determines his price, such as natural rubber and hydrogenated nitrile rubber price is 20 times worse;2, with the choice of mixture, environmental protection and environmental protection agent, the price is also very different;3, the rate of gum content, the higher the gum content, the higher the cost of nature;

- Q: How can the frictional properties of rubber improve?

- Because of its high elasticity and low modulus, the friction and wear properties of rubber are greatly affected by their physical and mechanical properties. The hardness of rubber is smaller, contacting with a rigid object, the real contact area is large, and the real size of the contact area is an important factor, so the friction rubber hardness, have more effect on the friction performance.

- Q: How can rubber and mould not be bonded when producing rubber products?

- Rubber is soft nature of the product, the draft (draft angle) is not to die. In other words, theoretical deduction is possible. However, the complex structure, a little larger, and often die adhesion is difficult to remove, and part of the solution can be solved with release agent.

- Q: Is the odour emitted by industrial rubber poisonous?

- In order to make all the necessary coordination agent in rubber, rubber Plasticating must first go through improving the plastic; then by mixing carbon black and all kinds of rubber and rubber additives are evenly mixed into rubber;

- Q: Is polyurethane and polyurethane rubber one thing?

- Plastics, such as Taiwan and Hongkong, are commonly referred to as plastics, so there is little point in distinguishing between plastics and rubber. From a theoretical point of view, the distinction between plastic and rubber is generally based on whether the glass transition temperature (Tg) of the material is above normal or below normal. Polymers that are generally less than Tg at normal temperature are called plastics (e.g., polyethylene, Tg, -78 degrees), while polymers with Tg temperatures higher than normal are called rubber.

- Q: What is food grade natural rubber?

- Is mainly made of natural rubber, made of natural rubber products, through the relevant national food contact using rubber testing standards, to reach the food grade.

- Q: Does the fuel pipe for automobiles belong to rubber products?

- If it is gasoline, remove the oil supply rack and the metal oil pipe on the chassis, to connect the need for some of the arc, are rubber material pipe.

Send your message to us

3.0mm PVC Green Conveyor Belt for Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords