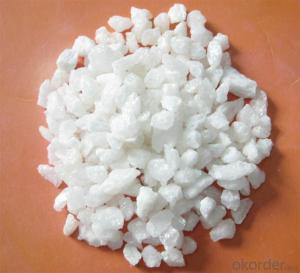

White Corundum Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Corundum (White fused aluminum oxide):

electrically fused in arc furnace with high grade processed alumina as raw material. It has higher hardness and slight lower toughness comparing with brown fused alumina. It is also characterized by its high purity, ability of self-sharpening, better cutting, less heat emit, higher efficiency, acid and alkali resistance, good thermal stability. As the abrasive materials, it is suitable for grinding high-speed, high carbon steel, as loose grains, it widely used for bonded and coated abrasives , polishing, precision casting and so on .

WFA Physical and Chemical Index

Chemical | Content(%) | |

Al2O3 | ≥99 | |

Na2O | ≤0.40 | |

SiO2 | ≤0.10 | |

Fe2o3 | 0.10 | |

Physical | ||

Cystal System | Hexahedron | |

Principal Crystalline Phase | Al2O3 | |

Color | White | |

True Density(g/cm3) | ≥3.9 | |

Bulk Density(g/cm3) | 1.75-1.95 | |

Mohs Hardness | 9 | |

Coefficient of Linear Expansion(1/ degree centigrade ) | 8.3×10-4 | |

LOI(%) | ≤0.10 | |

Name | Specification | |||||

Section Sand | 0-1mm 1-3mm 3-5mm 5-8mm 8-10mm | |||||

Size Sand | 24# 30# 36# 46# 60# 70# 80# 90# 100# 120# | |||||

Fine Powder | 180-0 200-0 325-0 | |||||

Chemical Composition | Al2O3 | Fe2o3 | SiO2 | Na2O | LOI | Bulk Density(g/cm3) |

Content(%) | ≥99 | ≤0.10 | ≤0.10 | ≤0.40 | ≤0.10 | ≥3.9 |

- Q: Which manufacturers have the best fire-proof materials with light weight?

- Recommend Hubei Boyuejia Industrial Co., Ltd. It is a specialized high-tech enterprise that integrates research and development, production, sale and installation of new lightweight fireproof partition panel, partition panel, new partition panel and mechanical?equipment. Products are lightweight, fireproof, waterproof, sound insulation, thermal insulation, fracture resistance, anti-permeability, environmental protection, strong constitutive property (dense humidity) and other superior performances. It can be widely used in all types of lightweight wall panel of all kinds of buildings, and is one of the preferred materials of plant, residence, hotel, office building and public buildings.

- Q: Are fire materials poisonous after burning?

- Refractories burning after the smell of toxic, gases are generally silica, alumina, sulfur oxides and so onRefractory material is not less than 1580 degrees of refractoriness, better thermal shock resistance and chemical erosion, low thermal conductivity and low expansion coefficient of non-metallic materials. Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 94% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, thermal shock resistance is poor. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, refractory material, good heat shock resistance, resistance to acid slag, widely used.

- Q: What are the materials for refractory materials? What are their names?

- Basic refractories in Magnesium Oxide and calcium oxide as the main ingredient, commonly used is brick. Magnesium Oxide 80% to more than 85% containing magnesia brick, has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and high temperature equipment.

- Q: The primary problem, does the gas permeable brick is fired refractory bricks(refractory) ?

- Yes. After moulding by casting in the firing of 1450 ° degrees.

- Q: What are the characteristics of thealuminium oxide refractory?

- The substance used in refractories must have the following characteristics and properties: 1, High stability: Anti-oxidation, anti-reduction and thermal decomposition; 2, High melting point of 2800 degree; 3, Low price. The magnesium oxide refractories have all these three characteristics and properties, particularlly in the aspects of melting point and stability .

- Q: What effect does aluminium powder play in refractory bricks?

- Aluminum powder is the main temperature resistant material ~ ~ ~ ~!

- Q: What are the characteristics of the carbon composite refractories?

- The features of carbon composite refractories: 1. It is with an aggressive high thermal shock resistance 2. Good resistance to molten steel and slag

- Q: What kind of refractory materials are used in the intermediate frequency furnace?The domestic boric acid can be used as a lining?, how much is the rate?

- Acid, neutral, basic and composite materials are used in intermediate frequency furnace. Boric acid is used according to the type of steel, the specific ratio is too generalized, and it shall be determined when the type of steel is detailed.

- Q: How is refractory material made?

- It is made from carbon materials.

- Q: Detailed description of magnesia dolomite refractory material?

- The use of low chromium or chrome free refractories is more and more widely used, developed countries in the development of chrome free refractories to replace the chromium containing material, through research and production practice show that dolomite refractories is the refining of AOD furnace, large cement kiln ideal material.

Send your message to us

White Corundum Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords