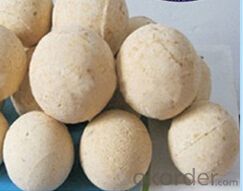

Raw Materials for Micro-Powder Bonded Corundum Refractory Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Micro-powder Bonded Corundum Refractory Alumina Ball

1. Savinh energy

2. High chemical stability

3.Good circulation used

Micro-powder Bonded Corundum Refractory Ball

At present it is the first choice in the field of ball-type hot stove.

Features:

1. Excellent energy saving

2. High mechanical strength

3. High chemical stability

4. Good circulation usage

5.ISO 9001:2008

Specification:

Brand | HXGD-80 |

Al2O3 | 80 |

Fe2O3 | 1.5 |

Refractoriness | 1790 |

Apparent Porosity | 19 |

Bulk Density | 2.8 |

Cold Crushing Strength | 40000 |

Linear Change After Heating | 0-0.2 |

Refractoriness Under Load | 1580 |

Hot Creep Rate | 0.2 |

Thermal Conductivity | 0.6 |

Thermal Shock Resistance | 26 |

Application | Ball-type |

Micro-powder Bonded Corundum Refractory Ball

Packaging Details:

Packaging Detail:

Plastic bag (50 kg)

Kraft paper bag (50kg)

Specific package be subject to customers’ special requirements.

Delivery Details:

Within 7 days after receipt of 30% deposit.

FACTORY:

- Q: Does anyone know the characteristics of refractory for glass kiln?

- Refractory is a kind of non-metallic material with refractoriness not less than 1580 ℃, which has better thermal shock resistance and chemical erosion resistance, low heat conductivity coefficient and low expansion coefficient. Refractoriness is the centigrade?temperature of refractory cone specimen wiyhout any load resisting high temperatures without melting down Refractory is widely used in industries like metallurgy, chemical, petroleum, machinery manufacturing, silicates, power, etc., which is mostly used in the metallurgical industry, accounting for 50% to 60% of total output.

- Q: Technical scheme of refractory for refuse incinerator

- Incinerator conditions and requirements for refractory lining1, working conditions: deal with rare earth, furnace body normal use temperature of 800~900 degrees.2, the specific requirement for refractory: refractory has good resistance to acid corrosion, thermal shock performance good stability and good high temperature.

- Q: What kinds of fireproof and fire retardant materials are there?

- general classification of fire retardant materials will use A, B in the home improvement supplies. A has the best flame resistance, followed by B.

- Q: What problems should be paid attention to while using refractory materials under a controlled atmosphere?

- Pay attention to the performance of the materials, and the use of non oxide materials!

- Q: Who knows the fire resistant level of the rock wool color plate?

- The rock wool color steel rock wool board is used in a area of high ??fire safety requirements. According to "interior decoration of buildings for fire protection design", the color steel rock wool board belongd to level A. Its life is more than 15 years and still can be used when the temperature is up to about 700 ℃, with maximum fireproofing hour of six hours. And the rock wool color plate is a environmentally friendly material, the preferred material in the construction industry .

- Q: Who knows which chrome refractories produced by the Henan refractory plant can be used for continuous casting?

- Chrome drainage sand can be used for coupling process there are many manufacturers do it, this is mainly a lot of chrome, chrome iron ore mainly refers to the drainage sand, adding ladle material amount regulator performance guide. Drainage sand as filling material of ladle bottom nozzle, one hand can be sintered at low temperature, to avoid joining the molten steel drainage sand floating accident, on the other hand, in the high temperature and long time refining steel surface can not meet the state of sintering is too thick, otherwise it will affect the automatic pouring rate, Hua Heng worth a try I'm not favored, my sky is the wind or rain rainbow you hate yourself in the manipulation of really useless emotional heart to still ache for breaking up before the sorry shuttle time in the moving picture of the clock in the opposite direction when the initial time begins to move back to love you

- Q: What is the type of heat resistance property of high temperature electric furnace ?

- According to the levels of refractoriness : Common refractories: & Gt: 1580 ℃ ~ 1770 ℃ advanced refractories: 1770 ℃ ~ 2000 ℃ AAA refractories; 2000 ℃

- Q: What refractories can withstand high temperature above 2100 degrees?

- Usually a dryer will not have such a high temperature. I do not know what you would use it for. Refractory cement coupled with quartz sand can work for 4 to 5 hours. So you can try cement coupled with corundum or superfine bauxite for better effect.

- Q: Who knows about the B-level fireproof insulation materials?

- Commonly used B-level materials: Molding polystyrene foam, extruded polystyrene board, gelatine powder polyphenyl granule heat insulating slurry. Although the polyurethane is not the commonly used material, but the 9mm composite of monolayer gypsum board and PU insulating material can reach B-level.

- Q: Is there a worker in (Jigang refractory plant)?

- Units in this way, it is necessary to slowly boil it, wages will come up. You are a labor worker, and can not share with the stock system staff. There's a difference between salary and vacation.

Send your message to us

Raw Materials for Micro-Powder Bonded Corundum Refractory Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords