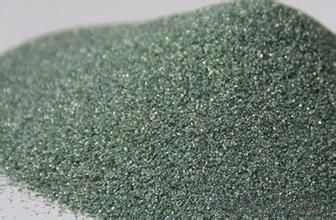

Raw Materials for Refractory - Black Silicon Carbide Carborundum

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Block | Material: | Silicon Carbide (SiC) |

| Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | Model Number: | SIC | Brand Name: | CNBM |

| grade: | refractory | usage: | metallurgical additive | application: | lapping and polishing |

Packaging & Delivery

| Packaging Details: | 1.1000kgs in a super big bag 2. 25kg/bag with 40 bags in a big bag 3. 25kg/bag with 40 bags on one pallet |

| Delivery Detail: | within 7 days |

picture

98.5% pure SIC

Black Silicon Carbide is produced with high temperature in a electric resistant furnace from a mixture of quartz sand and petroleum coke. Its hardness is between that of fused alumina and synthetic diamond and mechancial intensity of it is also greater than that of fused alumina. It is brittle and very sharp and has a certain degree of electrical and heat conductivity.

Chemical composition% | |||

Grit | SiC | F.C | Fe2O3 |

F12-90 | ≥98.5 | ≤ 0.2 | ≤ 0.6 |

F100-120 | ≥98.00 | ≤ 0.3 | ≤ 0.8 |

F150-220 | ≥97.00 | ≤ 0.3 | ≤ 1.2 |

Application:

Grinding non-ferrous material rock stone leather rubber finishing tough and hard materials

Bonded abrasive tools lapping and polishing

Widely used as a metallurgical additive and refractory material

Specifications:

F12-F1200,P12-P2500

0-1mm,1-3mm; 6/10,10/18;200mesh,325mesh etc.

Other special spec. could be supplied as required.

Packing:

- Q: What advantage and disadvantages it has compared to common fire insulation materials

- Main advantage of A-level fire proof heat retaining plate is A-level non-conbustibility. Now residential areas strictly require the external walls to be high-level fire proof, to be specific, high fire resistance, non combustible. Standards for evaluation varies according to different types, which includes anti-corrosion, acid and alkali resistance, waterproof, anti termites and so on. Disadvantage is the insulation effect is quite ordinary. It will absorb water, get deformed, need some water prevention measures after constrcuting thermal insulating layer for it. Its thermal conductivity far below the benzene plate, and plastic extruded palte, half the thickness of the polyurethane insulation layer can reach heat perservation effectiveness of the benzene plate and extruded plate of the same thickness.

- Q: Can anyone tell me what material the first rate fire resistant door is?

- Class A fire door materials are mainly steel, wood, steel and wood,and other materials. If there is filling material in a Class A fire door, it is generally the perlite. According to the actual situation in China, the fire doors and windows are divided into class A, class B, class C, whose minimum fire endurances are stipulated, namely class A 1.50h, class B 1.00h, Class C 0.50h. There are fireproof wooden doors and fireproof steel doors. whose main purpose is to achieve fire endurance time. But door closers are required to be installed.

- Q: What are the use of fire-resistant material and admixture?

- I am engaged in admixture and thus familiar. Welcome to exchange!

- Q: Who knows the refractoriness of high temperature lightweight firebricks?

- pores of high temperature lightweight refractory bricks is made by lightweight aggregate such as combustibles, foaming?agent, and hollow?sphere production with better thermodynamic stability. Refractoriness reaching 1200 ℃ or more is first grade refractories. fire resistance of building blocks of 100mm thick can reach 225 minutes, 200mm thick brick 480 minutes.

- Q: How long is the fire-fighting time of A class fire resisting window?

- Fire resisting window' duration of fire resistance: A class window, fire insulation ≥1.50h and fire resistance integrity ≥1.50h. Fire resisting window can be divided into three kinds: 一. window frame and sash framework adopt fire resisting window with steel manufacture ; 二. window frame and sash framework adopt fire resisting window with wooden manufacture; 三. window frame adopt steel and sash adopt wooden material or window frame adopt wooden material and sash framework adopt fire resisting window with steel material.

- Q: What is unshaped refractory?

- Concrete。 Early concrete technology appears, it is not forming products in the heat furnace, some parts such as pit heating furnace furnace wall, rotary kiln mouth ring, cutting slope and discharge chamber wall, etc., are able to design large masonry (top heating block weighing 3-4 tons) made concrete. Concrete cattle production method is to pour the material into the model, vibration molding, after the release of heat treatment, to provide users in addition to large blocks, weight, in use, and machine pressure brick no essential difference. The amount of water used in the casting material produced by the manufacturer is less than 10% above that in the field, and the processing quality is good and the quality is stable. As the bricks are large and heavy, the site shall have lifting equipment. As long as the site can be hoisted, the concrete shall be used as far as possible, or smaller ones, and some people can lift it. Concrete does not require the user to do a special heat treatment, this point is very meaningful.

- Q: What is the principal part of silicious refractory material

- Shenzhen Longgang Jiangyou Hua Boiler Accessories Co., Ltd. is specialized in refractory cement, refractory mortar, refractory clay, refractory aggregate and perlite. And other refractory | thermal insulation material, it has cooperated projects in Shenzhen, Huizhou, Dongguan, Guangzhou, Foshan, Zhuhai and other sites. For more information you can find our website on Baidu.

- Q: What's the definition of fire endurance of the fire-resistant coating for steel structure?

- 1. Fire endurance. Conduct fire resistance test of any building component according to the standard time-temperature curve, and the time when it is subjected to the fire to the time when it loses support capability or fire insulation function or its integrality is destroyed is referred to fire endurance. 2. Steel has relatively low fire endurance which is usually 0.25h only, namely 15 minutes; 3. Of steel structure buildings, steel can be used as beams, pillars, etc. but its fire endurance is not enough (usually these components have higher requirement on fire endurance, and take pillar as an example, it is usually demanded that the fire endurance should be 2-3h), and under this condition, it needs to brush fire retardant coating so as to raise the fire endurance. As to the specific quantity or types of the fire retardant coating, it is decided upon the actual conditions. In short, the building material needs to meet the required fire endurance of the buildings.

- Q: What are the construction measures of refractory material in winter? Please descriptive briefly.

- The temperature is low in winter, so refractory bulk materials should be stirred evenly on time to avoid freezing.

- Q: What's the poured refractory material?

- According to its category, raw material of basic refractory: Mainly magnesite (magnesia), dolomite, lime, olivine, serpentine, high alumina material (sometimes neutral); main neutral raw material: chromite, graphite, silicon carbide (artificial).

Send your message to us

Raw Materials for Refractory - Black Silicon Carbide Carborundum

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords