Welding Aluminum Sheets - AA1XXX Coated Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1xxx Coated Aluminum Coils Used for Construction Description

AA1xxx Coated Aluminum Coils Used for Construction are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

AA1xxx Coated Aluminum Coils Used for Construction have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of AA1xxx Coated Aluminum Coils Used for Construction

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

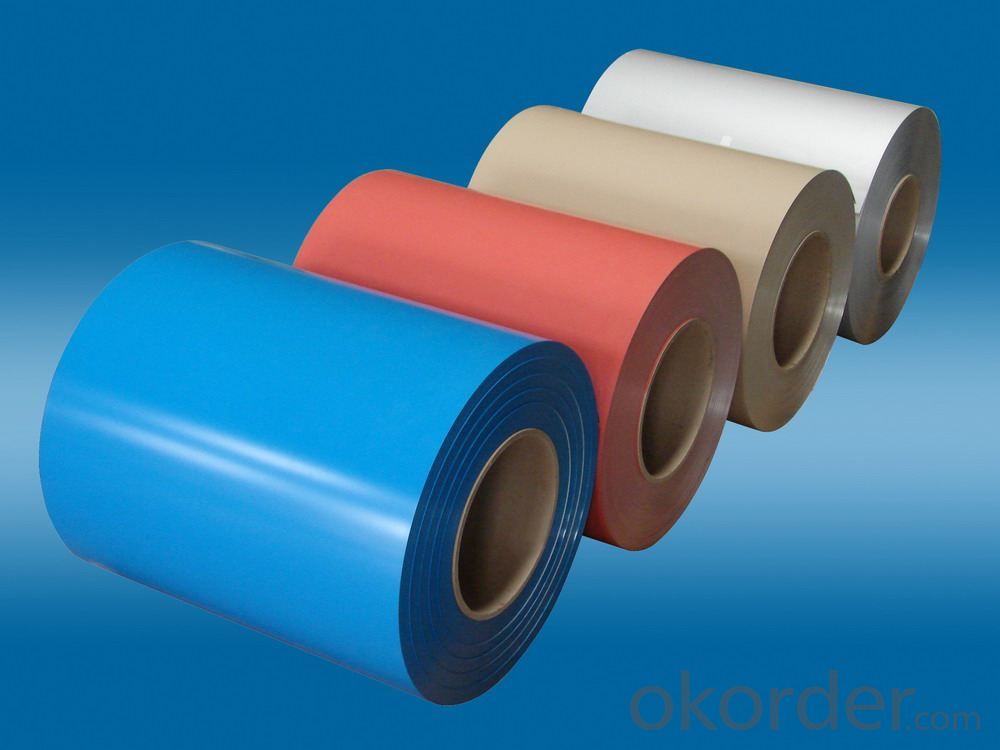

3.AA1xxx Coated Aluminum Coils Used for Construction Images

4. AA1xxx Coated Aluminum Coils Used for Construction Specification

Alloy | AA1xxx |

Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

Thickness | 0.03mm-3.0mm |

Width | 30mm-1700mm |

Coating | PE,PVDF,Epoxy |

Painting Thickness | Standard 16-25 Mic, max 40 Mic |

Color | According to RAL colors or customers' samples |

Standard | GB/T 17748-1999 |

5. FAQ of AA1xxx Coated Aluminum Coils Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What are the different methods of bending aluminum sheets?

- There exist multiple techniques for bending aluminum sheets, each possessing its own merits and limitations. Some frequently employed approaches include: 1. Press Brake Bending: This method entails securing the aluminum sheet between a punch and a die on a press brake machine. Force is then applied through the punch, which pushes against the die to bend the sheet. Press brake bending is most suitable for high-volume production and ensures accurate and consistent bends. 2. Roll Bending: Also referred to as the three-roll bending process, this technique employs a set of three rollers to gradually shape the aluminum sheet as desired. Roll bending is effective for creating cylindrical or conical forms and finds applications in industries such as automotive and aerospace. 3. Stretch Bending: In this method, the aluminum sheet is clamped at both ends while a stretching force is applied in the middle. This results in both elongation and bending of the sheet, yielding a curved shape. Stretch bending is commonly utilized to produce curved profiles with a smooth and uniform finish. 4. Heat Bending: By subjecting the aluminum sheet to heat, it becomes more malleable and can be easily shaped into desired forms. Heat bending is often carried out using a heat gun or an oven to soften the metal, followed by manual or mechanical bending. This technique is beneficial for crafting intricate and complex shapes. 5. Incremental Bending: This technique involves bending the aluminum sheet in multiple steps or increments, with the bend angle gradually increasing after each step. Incremental bending provides greater control over the bending process and is commonly employed for forming U-shaped or V-shaped bends. 6. Roll Forming: In roll forming, the aluminum sheet is fed through a series of rollers, each bending the sheet a little more. This continuous process is well-suited for producing long and consistent bends, commonly seen in the manufacturing of aluminum profiles and extrusions. It is important to note that the choice of bending method depends on various factors, including the desired bend angle, the thickness and grade of the aluminum sheet, the required precision, and the production volume.

- Q: what's the size of aluminum sheet circle?

- General diameter of aluminum sheet circle is 600mm, it at least needs aluminum sheet with a 604mm length and width, retain 2-3mm pressing edge. user use cold squezz method to transform the aluminum sheet circle into various standard capacitor shell, aluminium collapsible tube shell, which are broadly used in electron industry, daily chemical industry, medicine, education and automobile products,electrical appliance, heat preservation, machine manufacturing, automobile,spaceflight,military industry,mould, construction, printing and other industries.

- Q: what will happen when aluminum sheet is put into copper chloride solution?

- the chemical equation of the reaction, 2Al+3CuCl2=2AlCl3+3Cu, the phenomena when aluminum sheet is put into copper chloride solution: there is red solid generating on the surface of aluminum sheet.

- Q: What characteristics distinguish aluminum sheets from other types of sheets?

- <p>Aluminum sheets are lightweight, corrosion-resistant, and have excellent thermal and electrical conductivity. They are commonly used in construction, automotive, and packaging industries. In contrast, other types of sheets, such as steel sheets, are heavier and stronger but less resistant to corrosion. Plastic sheets are lightweight and flexible but have lower strength and thermal conductivity. Copper sheets offer high thermal and electrical conductivity but are more expensive and less resistant to corrosion than aluminum. Each type of sheet has unique properties that make it suitable for specific applications.</p>

- Q: why can't aluminum sheet burn after polishing?

- because aluminum will rapidly formulate dense oxide film once being exposed in air, oxide film will generate after polishing, it can't burn.

- Q: Can aluminum sheets be anodized with custom colors?

- Yes, aluminum sheets can be anodized with custom colors. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum, and during this process, dyes can be applied to achieve a wide range of custom colors.

- Q: Can aluminum sheets be used for interior design purposes?

- Yes, aluminum sheets can be used for interior design purposes. They are versatile, lightweight, and durable materials that can be used for various applications such as wall cladding, ceilings, countertops, backsplashes, and decorative accents. Aluminum sheets offer a modern and sleek aesthetic, and their availability in different finishes and colors allows for customization to fit various design styles and preferences.

- Q: Over 5 billion aluminum cans are recycled each year. If laid end to end, these cans would form a line reaching from?

- IDK, but this may give you some idea of 1 billion. 1 Billion seconds ago.. It was 1959 1 Billion minutes ago... Christ was alive.

- Q: What are the different types of surface coatings for aluminum sheets?

- There are several types of surface coatings available for aluminum sheets, including anodizing, powder coating, painting, and laminating.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, you can use aluminum sheets to create a green building. Aluminum is a sustainable material due to its recyclability and energy efficiency in production. It has a high recycled content rate, reducing the need for raw material extraction. Additionally, aluminum's lightweight nature can lead to reduced energy consumption in transportation and construction. Its durability and resistance to corrosion can extend the life of a building, further contributing to sustainability. However, it's important to consider the entire lifecycle impact, including the energy used in aluminum production, and to source aluminum responsibly to ensure a truly green building.</p>

Send your message to us

Welding Aluminum Sheets - AA1XXX Coated Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords