Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

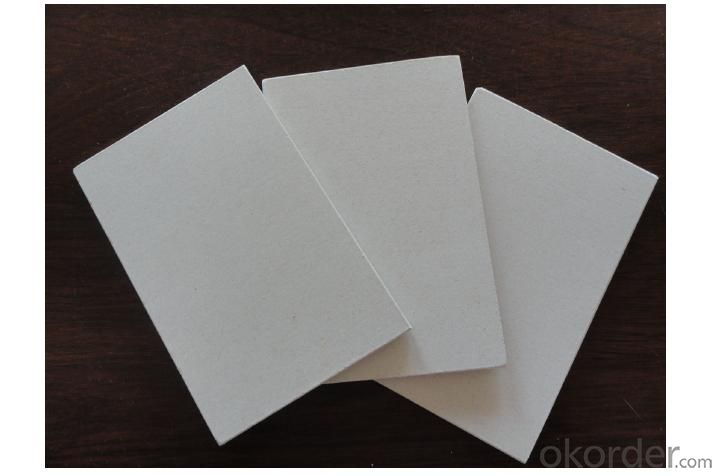

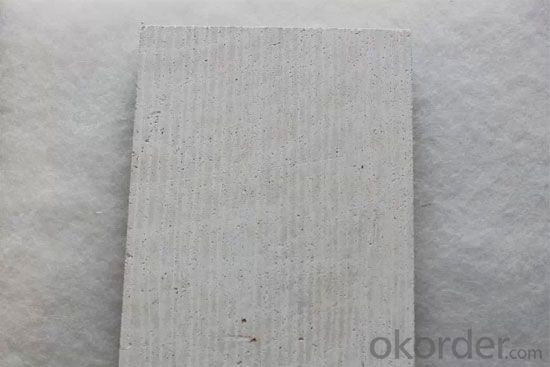

It can be applied not only in the interior use but also in the outdoor walls. It has low water absorption rate and high impact resistant ability. These advantages make it suitable for any purposes of applications.

Product Applications:

1) Old and new building curtain walls, exterior walls and other outdoor systems

2) European and American styles of architecture and high-end villa roof

3) Indoor hall, office, building facade and podium

4) Kitchen, bathroom, bathrooms, changing rooms and other damp places

5) Subway stations, tunnels and underground works

6) Interior wall decoration system

7) High quality requirements of the ceiling

8) Environmental requirements, particularly Germany occasions

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

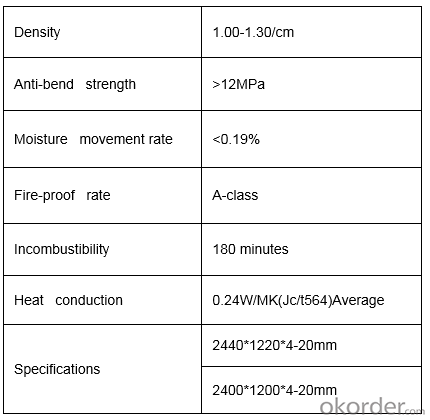

Main Product Features:

1) 100% non-asbestos

2) Density: 1,000 - 1,400kg/cbm

3) Coefficient of thermal expansion: 0.24W/MK (JC/T54)

4) Bending strength: over 13MPa (GB/T7019-1997)

5) Linear expansion rate: 0.1%

6) Water absorption rate: less 0.19% (GB/T7019-1997)

7) Water penetration rate: 0%

8) Water content: 10%

9) Incombustibility according to CNS 6532 and BS 476 standards

10) Two point five three hours of fire rating for 6mm wall system with W-CSP concrete

11) Radioactivity: GB6566-2000 standards

12) Characteristic: nonflammability A grade (GB-8624-1997)

13) Light weight

14) The wall is solid and firm inside, resistant to impact pressure

15) Painting, tiling and nailing is possible in the new system

16) Noise reduction can be up to 46dB

17) Good efficiency

18) Working environment can keep it dry and clean for better management .

19) Applications: can be used for partitions, interior walls, pipeline and conduit compartments, stair space, exterior walls, ceiling boards and pillar wrapping.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: Silicon calcium board is mostly used for indoor decoration where.

- Decorative calcium silicate board thickness of 4-20mm, length and width to 1220 * 2440mm mainly. At the same time to have a large size of calcium silicate board processed into a decorative calcium silicate ceiling, its anti-sagging varieties and other advantages, is widely used in the ceiling. Decoration with a more comprehensive performance, the most used or interior decoration, because it is resistant to moisture, long life, anti-subsidence, is used as a good material for the ceiling shape. In addition, the decorative silicate board can also be used for wall, floor, furniture, road noise, used to do noise wall, sound absorption wall, sound absorption ceiling, meet the panel are very good choice. Calcium silicate board in the case of high temperature combustion is not easy to burn, it will not produce toxic smoke, in the KTV, dance halls, hotels, restaurants and other places have a greater use. Calcium silicate board waterproof performance, for indoor bathrooms, toilets, toilets and other places often need water is the best choice, long-term use will not occur distortion and expansion of the phenomenon, the performance is relatively stable. Calcium silicate board strength is high, even if only 6mm of calcium silicate board than the traditional 9.6mm gypsum board light, high stability, strong and durable, will not easily crack damage, can be safe to use. Others, such as the size of the strict control in the specified range, heat insulation and long life is no longer said that this is, after all, it is more prominent features of the few.

- Q: Is the calcium silicate board and the Etter plate the same material?

- Quality answer Simply said the same kind of material. The Etter board is the product of Etterit in Belgium and it should be called a fiber cement board.Endite is the inventor of the fiber cement board. Manufacturing history for more than a century.

- Q: Is the calcium silicate board gypsum board?

- Calcium silicate board is mainly made of siliceous materials and calcareous materials through a variety of production processes, with good fire and water, light high strength, long life, heat and sound absorption, high density and other characteristics, is the future light The main direction of the development of the partition wall. Gypsum board mainly by the construction of gypsum as raw material, the surface of a special paper for the face, after processing from the plate, but also has a light high strength, heat and sound absorption, construction and other characteristics.

- Q: External wall of calcium silicate board seams posted why the grid is also cracked

- Ordinary caulking agent is not enough, with the toughness of the sealing agent is more appropriate, with toughness anti-cracking, it is recommended to use the home of the heart of the card to worry about toughness sealant (TB).

- Q: Silicon calcium board and mineral wool board difference between the price is the price, and the advantages and disadvantages of the material

- Mineral wool board there is a better kind of engineering board and the like, the price is even higher. Specifically to see where you used, the office ah ah hospital this kind of mineral wool board with more, sound-absorbing good. Landlord can refer to the next

- Q: Jinfu calcium silicate board and Matsumoto easy hair board that kind of good?

- Fiber reinforced calcium silicate board Calcium silicate board and fiber reinforced calcium silicate board as a new building materials, are based on calcium materials, siliceous materials as the main binder materials and reinforcing fibers (the former fiber to inorganic mineral fiber, asbestos fiber and other loose short fiber to enhance Materials, which enhance the fiber to cellulose fiber, alkali-resistant glass fiber instead of asbestos fiber) as the main raw material, through the pulp, molding, high temperature and high pressure saturated steam curing made of new plate.

- Q: Calcium silicate board water absorption on the performance of the plate have any effect

- Calcium silicate board if the water after the impact of the plate have a certain impact, but will not loose will not be deformed, and then back to the plate after the original strength will be restored

- Q: What are the extruded boards and calcium silicate board adhesives?

- Calcium silicate board on the requirements of the adhesive is relatively lower, generally used in polymer mortar mortar on it. Or else I add my Baidu HI chat, perhaps more exchanges

- Q: What is the difference between gypsum board and silicon calcium board?

- Gypsum board is a building gypsum (that is, CaSO4) as the main raw material, mixed with appropriate amount of additives (adjust the rate of condensation) and fiber to do plate core, with a special plate for the face, the processing of the plate. Strength is not high, not wet

- Q: What is the difference between high-density fiber cement pressure plate and calcium silicate board?

- Calcium silicate board is autoclaved, the pressure plate is autoclaved and not autoclaved, autoclaved weather resistance is better, the same pressure, the density of calcium silicate board lower, because the formula has a lighter lime, There is no cement pressure plate.

Send your message to us

Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords