Vinyl Coated Aluminum Coil Stock - PVDF Solid Coated Aluminum Coils for Lids and Tabs with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of PVDF Solid Coated Aluminium Coils Used for Lids and Tabs with Good Quality

We have different colors for PVDF coated aluminum coils used for lids and tabs of beverage cans. RAL numbers are standard. We also can adjust coating according to color of customers and offer personalized services.

We professionally produce aluminium coated strips used for can tabs or ring-pulls. During production, we use large wave shear, transverse shear and longitudinal cut system so as to meet different specifications of customers.

Based on ordinary aluminum, we add Mn and Mg, so as to increase tensile strength and elongation. Normally we use 5182, H48 for production.

2. Main Features of PVDF Solid Coated Aluminium Coils Used for Lids and Tabs with Good Quality

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

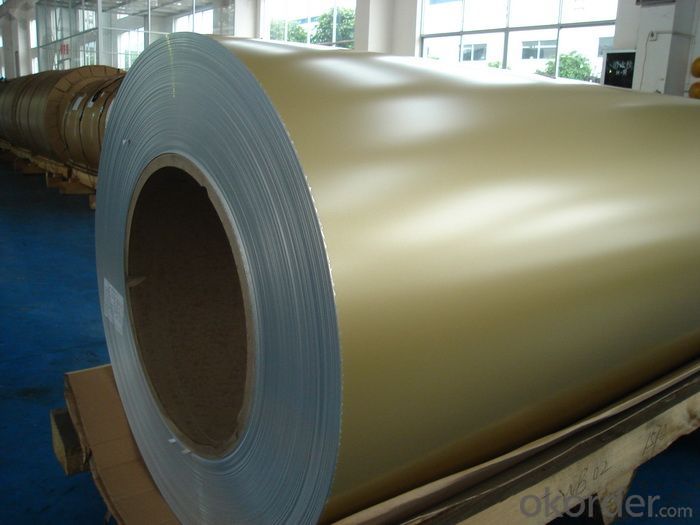

3. PVDF Solid Coated Aluminium Coils Used for Lids and Tabs with Good Quality Images

4. Specification of PVDF Solid Coated Aluminium Coils Used for Lids and Tabs with Good Quality

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: hello I'm building a TIG welder and have found the output from my stick welders to be not so good for aluminum(60 Hz on one). I've heard that high frequency AC is the way to do AL but am not sure what constitutes high. I do have a nice miller gas driven welder also that is maybe triple the frequency of my line driven one but still had issues with it. does anyone know of an actual # ? I may be able to build an inverting PWM supply eventually to do this but am not sure what I would need it to do. does anyone have any data that might help? any data/tips about aluminum would be appreciated, thanks in advance. FYI I do understand why AC works so much better on AL, what with the oxides that are always present.

- NO... the TIG rods are uncoated and will not be able to create the shielding gas like coated rods would when used in an ARC welder. TIG (Tungsten Inert Gas) uses a shielding gas supplied from a tank, the aluminum rods are used as filler material and metled into the weld by the operator by using the arc from the tip as the heat source. Two different welding processes, hence the need for two different types of rods...

- Q: is Aluminum wrotten with a 2 behnd it?

- Are you asking if it's a diatomic molecule? Because then the answer would be no. Aluminum is a metal. The only diatomic molecules are Hydrogen, Nitrogen, Oxygen, Chlorine, Flourine, Bromine and Iodine. And even those are only written when they are by themselve and not part of a chemical compound.

- Q: Are there any specific guidelines for the storage of aluminum coils?

- Aluminum coils have specific guidelines for storage, and here are some key considerations: 1. When storing aluminum coils, it is necessary to place them in a clean, dry, and well-ventilated area. The storage facility should be free from excessive humidity, direct sunlight, and temperature fluctuations. 2. To prevent damage, handle the coils with care. Appropriate lifting equipment should be used to lift them, avoiding any bending or deformation. 3. Proper support is crucial when stacking the coils to prevent distortion or collapse. It is recommended to stack the coils horizontally on a flat surface, preferably on pallets or racks. Sufficient space should be left between each coil to allow for ventilation. 4. Protect the coils from dust, dirt, and moisture. Cover them with suitable protective materials like plastic sheets or tarpaulins to prevent contamination or oxidation. 5. Labeling each coil with relevant information, such as the alloy type, size, and production date, is advisable. This helps with easy identification and efficient inventory management. Additionally, maintaining an organized storage system prevents damage and enables efficient retrieval. 6. Regular inspection and inventory checks are necessary to identify any signs of damage or deterioration. Rotate the coils to ensure proper usage and avoid prolonged storage that could affect quality. It is important to note that these guidelines may vary depending on the specific requirements of the manufacturer or supplier. Therefore, it is advisable to consult the manufacturer's recommendations or seek professional advice for the storage of aluminum coils.

- Q: What are the different packaging weights available for aluminum coils?

- The available packaging weights for aluminum coils vary depending on specific requirements and applications. Aluminum coils can be packaged in a range of weights, typically measured in pounds or kilograms. The specific packaging weight depends on factors such as coil size, thickness, and the quantity needed by the customer or industry standards. For larger industrial applications, common packaging weights for aluminum coils can range from as low as 500 pounds (or 227 kilograms) to several thousand pounds (or several metric tons). These weights guarantee secure and efficient transportation and storage, as well as easy handling and loading. It is worth mentioning that the packaging weight of aluminum coils can be customized to meet specific needs. Manufacturers and suppliers often collaborate closely with customers to determine the most suitable packaging weight based on transportation requirements, storage space limitations, and industry regulations. In conclusion, the packaging weights for aluminum coils are flexible and can be personalized to meet individual needs, ensuring safe and convenient handling while satisfying the demands of different industries.

- Q: How are aluminum coils used in the production of beverage cans?

- Aluminum coils are used in the production of beverage cans as they are rolled into thin sheets and then shaped into the cylindrical form of a can. These coils provide the necessary material for manufacturing cans, allowing them to be lightweight, durable, and resistant to corrosion.

- Q: What are the benefits of using aluminum coils?

- There are several benefits of using aluminum coils. Firstly, aluminum is a lightweight material, making it easier to handle and install. Secondly, aluminum is highly resistant to corrosion, ensuring the durability and longevity of the coils. Additionally, aluminum coils have excellent heat transfer properties, allowing for efficient cooling or heating. Lastly, aluminum is a sustainable and recyclable material, making it an environmentally friendly choice.

- Q: Can aluminum coils be used in solar thermal systems?

- Certainly, solar thermal systems can utilize aluminum coils. Aluminum, renowned for its remarkable thermal conductivity, is widely employed in heat exchangers. Within a solar thermal system, aluminum coils can serve as a component of the heat exchanger, effectively transmitting the harnessed solar energy to the working fluid. By enabling efficient heat transfer, these aluminum coils guarantee the optimal utilization of the captured solar energy when heating water or other fluids. Moreover, aluminum's lightweight nature and resistance to corrosion render it an ideal material for outdoor applications like solar thermal systems.

- Q: Are there any limitations on the powder coating of aluminum coils?

- Yes, there are some limitations on the powder coating of aluminum coils. One limitation is the size and shape of the coil, as certain complex shapes may be difficult to coat evenly. Another limitation is the thickness of the coating, as excessive thickness can lead to cracking or peeling. Additionally, the presence of any surface contaminants or oils can affect the adhesion and quality of the powder coating. Proper surface preparation is crucial to overcome these limitations and achieve a durable and high-quality coating on aluminum coils.

- Q: Can aluminum coils be used in solar panel systems?

- Solar panel systems can indeed utilize aluminum coils. Aluminum is commonly selected as the material for frames and supports in solar panels because of its favorable combination of lightness and strength. Its resistance to corrosion, durability, and impressive thermal conductivity make it an ideal choice for enduring severe weather conditions and efficiently dispersing heat generated by the panels. Furthermore, aluminum is highly recyclable, which aligns perfectly with the environmentally conscious nature of solar energy systems. In conclusion, incorporating aluminum coils into solar panel systems enhances their efficiency, lifespan, and eco-friendliness.

- Q: This question asks for a brief explanation of the process involved in manufacturing aluminum coils.

- <p>To make aluminum coil, start with high-quality aluminum ingots. These are melted in a furnace and then poured into a casting machine to create a continuous cast strip. This strip is passed through a series of rollers to reduce its thickness and achieve the desired width and thickness. The rollers apply heat and pressure, gradually forming the aluminum into a coil. The coil is then cooled, often using water, and wound onto a mandrel for storage or further processing. Quality control checks are performed throughout the process to ensure the coil meets specific strength, thickness, and surface finish requirements. The final product is a tightly wound aluminum coil ready for use in various industries such as construction, automotive, and packaging.</p>

Send your message to us

Vinyl Coated Aluminum Coil Stock - PVDF Solid Coated Aluminum Coils for Lids and Tabs with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords