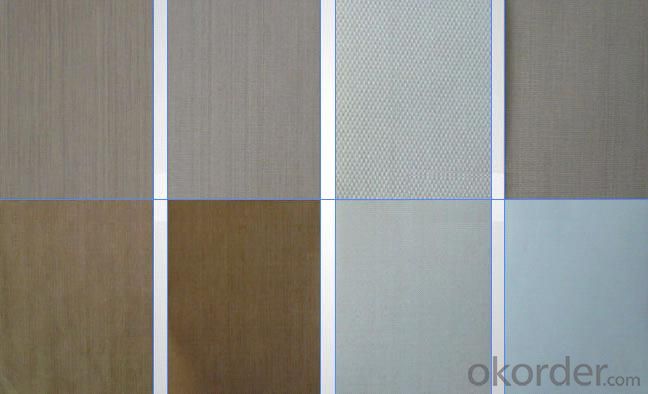

Vermiculite-Coated Fiberglass Fabric in Different Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicone Coated Fiberglass Fabric of Different Colors

Fiberglass Fabric Description

Silicone coated fiberglass fabric is a fiberglass cloth, which possesses the properties of temperature resistance, anti-corrosion, high strength and is coated with organic silicone rubber.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

It has been widely used in construction, electric insulation,

chemical industry, pipeline ductile conjunction, large generating

Corrosion proofing field, machinery, metallurgy, sealing and so on.

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

c) Satin weave: compared with plain weave and twill weave, it is of high density,high intensity, with a soft and loose structural weave with a good texture. It is applicable for use as a higher reinforced material in machinery.

d).Gauze weave: said lattice twist weave. It can be used in spread model curtain,resin reinforced emery wheel gray cloth and lattice embed belt.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q: What is the typical thickness range for fiberglass fabrics?

- The typical thickness range for fiberglass fabrics is between 0.1mm to 3mm.

- Q: Can fiberglass fabrics be used for insulation in refrigeration systems?

- Yes, fiberglass fabrics can be used for insulation in refrigeration systems. Fiberglass is a popular choice for insulation in various applications, including refrigeration systems, due to its thermal resistance and durability. It helps to maintain the desired temperature within the system by minimizing heat transfer.

- Q: Can fiberglass fabric be used for insulation in silos?

- Indeed, insulation in silos can be achieved by employing fiberglass fabric. Renowned for its remarkable thermal insulation capabilities, fiberglass fabric emerges as a fitting option for silo insulation. By effectively hindering heat transfer, it ensures consistent temperatures within the silo, safeguarding the stored materials against drastic fluctuations in temperature. Furthermore, fiberglass fabric exhibits resistance to moisture and chemicals, rendering it a resilient and enduring insulation material for silos.

- Q: Can fiberglass fabric be used for making curtains and drapes?

- Yes, fiberglass fabric can be used for making curtains and drapes. Fiberglass fabric is a versatile material that offers several advantages for this application. It is lightweight, durable, and has excellent resistance to heat, chemicals, and moisture. Fiberglass curtains and drapes can provide privacy while allowing natural light to filter through, creating an elegant and modern look. Additionally, fiberglass fabric is easy to clean and maintain, making it a practical choice for curtains and drapes in various settings such as homes, hotels, offices, and hospitals.

- Q: What is the tear strength of fiberglass fabric?

- The tear strength of fiberglass fabric can vary based on several factors, including fabric thickness, weave type, and material quality. Typically, fiberglass fabric exhibits high tear strength due to the resilient and strong nature of its fibers, surpassing the strength of various textile materials like cotton, nylon, or polyester. However, it's important to consider that tear strength may also be influenced by external elements like temperature, exposure to chemicals or UV radiation, and the presence of defects or damages in the fabric. Consequently, it is advisable to consult the manufacturer's specifications or conduct a tear strength test to precisely determine the tear resistance of a particular fiberglass fabric.

- Q: How is fiberglass fabric used in the production of composite materials?

- Fiberglass fabric is commonly used in the production of composite materials due to its exceptional strength and durability. It is a type of fabric made from thin strands of glass fibers that are woven together to form a flexible and lightweight material. In the production of composite materials, fiberglass fabric serves as a reinforcement layer. It is often combined with a resin matrix, such as epoxy or polyester, to create a composite structure that possesses enhanced mechanical properties. The process begins by applying the resin matrix to the fiberglass fabric. This is typically done through a technique called wet layup or wet lay-in. The fabric is saturated with the resin, ensuring that it is uniformly coated. The excess resin is then removed to achieve the desired resin-to-fiber ratio. Once the resin is applied, the fiberglass fabric is often layered or stacked to create a composite laminate structure. Multiple layers can be added to increase the strength and stiffness of the final product. This layering technique allows for a tailored reinforcement, where the fabric can be strategically placed to provide strength in specific areas. After the fabric is layered, the composite structure undergoes a curing process. This involves subjecting the materials to heat or pressure, which activates the chemical reaction in the resin matrix. As the resin cures, it hardens and bonds the fiberglass fabric layers together, creating a strong and rigid composite material. The use of fiberglass fabric in composite production offers several advantages. Firstly, fiberglass has excellent tensile strength and stiffness, making it ideal for applications that require structural integrity. It also has high resistance to corrosion, moisture, and chemicals, making it suitable for various environments. Additionally, fiberglass fabric is lightweight, which helps reduce the overall weight of the composite material, making it more efficient for applications where weight is a concern. Overall, fiberglass fabric plays a crucial role in the production of composite materials by providing strength, durability, and flexibility. Its incorporation into the resin matrix creates a composite structure that combines the best properties of both materials, resulting in a wide range of applications across industries such as aerospace, automotive, construction, and marine.

- Q: Are there any specific storage requirements for fiberglass fabrics?

- Fiberglass fabrics have specific storage requirements. It is highly advised to keep them in a cool, dry, and well-ventilated place to prevent moisture absorption and potential fabric damage. To avoid degradation of strength and appearance, it is crucial to store them away from direct sunlight, as prolonged exposure to UV rays can be harmful. Furthermore, it is vital to keep the fabrics far from heat sources or open flames to minimize the risk of fire. Additionally, it is essential to store them separately from chemicals, solvents, or oils that may cause staining or deterioration. By storing fiberglass fabrics properly, their quality and lifespan can be maintained.

- Q: Does fiberglass fabric shrink?

- Under certain conditions, fiberglass fabric has the ability to shrink. Fiberglass fabric is composed of glass fibers that are either woven or knitted and then coated with a resin or silicone finish. Although the glass fibers themselves do not shrink, the coating on the fabric can experience shrinkage when exposed to heat or other influencing elements. When fiberglass fabric is subjected to high temperatures, such as during manufacturing or exposure to excessive heat, the resin or silicone coating may either melt or shrink. As a result, the fabric can contract and decrease in size. Moreover, if the fabric is not adequately cured or dried after being coated, it may also shrink. It is worth noting that the extent of shrinkage in fiberglass fabric can vary based on the specific type of coating, the manufacturing procedure, and the conditions it is exposed to. Therefore, it is advisable to diligently adhere to the manufacturer's instructions and guidelines to prevent any potential shrinkage. To sum up, while the glass fibers in fiberglass fabric remain unaffected by shrinkage, the coating on the fabric can experience some shrinkage when subjected to heat or other factors.

- Q: Can fiberglass fabric be used for insulation blankets?

- Indeed, insulation blankets can make use of fiberglass fabric as it possesses exceptional thermal insulation properties, rendering it a favored option for insulation applications. Its lightweight nature, flexibility, and ease of molding into desired shapes further contribute to its popularity. Furthermore, fiberglass fabric exhibits resistance to high temperatures, chemicals, and moisture, thereby making it suitable for deployment across diverse industrial, commercial, and residential settings. Its non-combustible nature and low thermal conductivity not only enable it to effectively trap heat but also prevent energy dissipation. Consequently, fiberglass fabric emerges as an appropriate material for insulation blankets, delivering thermal insulation and bolstered energy efficiency.

- Q: Is fiberglass fabric breathable?

- No, fiberglass fabric is not breathable.

Send your message to us

Vermiculite-Coated Fiberglass Fabric in Different Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords