Variable Frequency Drive 11KV 2400KW VFD VSD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Voltage 3KV ~11KV AC Driver Inverter

General

CNBM high Voltage Variable Frequency Drives are designed to be highly reliable with high-performance, yet easy to use.It can satisfy users' need for changing the speed of fans or pumps,as well as improve the productivity.

The series are compatible with all types of three-phase medium voltage asynchronous motors.

Specifications

Variable Frequency Inverter

1.3KV ~11KV AC Driver Inverter

2.Suitable for motor speed regulation

3.Energy saving solutions

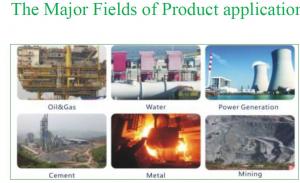

Typical Application

Thermal powerindustry: induced draft fan, blower, dust collection fan, compressor, sewage pump, boiler feed pump etc.

Petrochemical industry: main pumps, submersible pumps, injection pumps, circulating pump, boiler feed pump, halogen water pump, fan, descaling pump, mixer, gas compressors, extrusion machine, etc Mining and metallurgy: slurry pump, induced draft fan, blower,, dust removal fan, descaling pump, centrifugal feed pump, etc Cement manufacturing: water pump, boiler feed pump, halogen water pump, fan, descaling pump, mixer, gas compressors, induced draft fan, preheat tower fan,

Specification

Model | A03/050~ | A03/100~ | A03/175 ~A03/220 | A03/220~A03/400 | A03/220~A03/610 |

Capacity(kVA) | 250~630 | 630~900 | 900~1150 | 1150~2000 | 2000~3125 |

Rated output current (A) | 50~100 | 100~175 | 175~220 | 220~400 | 400~610 |

Motor power (kW) | 200~400 | 400~710 | 710~900 | 900~1600 | 1600~2500 |

Input frequency | 45Hz~55Hz | ||||

Rted input voltage | 3000V±10% | ||||

Input power factor | 0.95 (>20%load) | ||||

Efficiency | 0.96 with rated load | ||||

Output frequency | 0.5Hz~120Hz | ||||

Frequency resolution | 0.01Hz | ||||

Overload capacity | 120% 1 min, 150% immediately | ||||

Analogue input | 0~10V/4~20mA | ||||

Analogue output | 0~10V/4~20mA | ||||

Acceleration/deceleration time | 0.1~3000s | ||||

Digital output/input | expanded according to requirement | ||||

Ambience temperature | 0~40°C | ||||

Storage/transport temperature | -40~70°C | ||||

Cooling | air cooling | ||||

Ambience humidity | <90% without condensation | ||||

Altitude | <1000 m | ||||

IP class | IP20 | ||||

Size(mm)(W×H×D) | 3300×2480×1200 | 4900×2480×1200 | 6000×2580×1300 | ||

Weight (kg) | 3000 ~5000 | 5000 ~7300 | 7300~9200 | ||

- Q: Inverter alarm a043, how is it

- When a signal failure occurs, use the DTI board, if necessary, change P215. With P806 (Follow the parameter description) during operation can be converted to no encoder operation A043 is: n-actjump exceeds the allowable change speed of the speed encoder signal (P215) In addition, for the synchronous motor (P095 = 12): The motor speed is 2% higher than the inverter release time point. The inverter in the ready state can not exit. Check processing: Check if the cable is disconnected Check the tachometer to shield the ground Not only on the motor side but also on the inverter side The encoder cable does not allow disconnection Use only recommended encoders The encoder cable is not allowed to be laid with the power cable

- Q: Laptop power adapter is broken, which brand is better domestic

- What brand of your laptop brand? It is best to be original,

- Q: I have a 5.5 kilowatts of 4-pole motor, want to pass through the inverter, slow down to 130 per minute use, eliminating the need for speed,

- wo recommendations, the first, the use of vector control of the inverter, you are expected to run the frequency of about 5Hz, this time, ordinary V / F inverter output torque may be small, not necessarily meet the requirements, of course, if it is High-end imported inverter, the problem should be small, with the domestic vector inverter, the frequency can also be full torque output;

- Q: ASUS notebook power adapter can be universal? is it?

- Yes, see the same parameters as the interface on the line

- Q: Octopus AC Servo motor can be driven with ordinary inverter?

- If it is synchronous motor, it depends on whether you choose the inverter is compatible with the synchronization machine, most of the incompatible. As you said the situation, the motor 8 pole, may be synchronous motor. Specifically, you can compare the rated speed and rated frequency to see if there is a slip rate to determine whether it is synchronous or asynchronous motor.

- Q: The notebook power adapter flashes

- The problem is very simple Well, used to know all the notebook Kazakhstan, the adapter has a light above, if it is lit that is the problem of the notebook, the other side of the notebook above also have a power indicator, the notebook above prompted the red, but not Rushed, that is, the problem of the notebook, the computer problem, you directly on the factory is finished, if the insurance, and casually find a place to repair a Kazakhstan, 50-80 yuan if the adapter is bad, buy a generic You can, but also more than 50 points, the last time I bought a bad 58 yuan, ASUS GM, to help people in the end, to give you a shop to buy the adapter, you ask the owner of Kazakhstan to get,

- Q: Which machines are used for the frequency converter

- Used on a motor that needs to change the speed to change the power.

- Q: How many types of CVT are classified?

- CVT (Continuously Variable Transmission) technology that is continuously variable technology, which uses the belt and the working diameter of the main and driven wheel to match the power to transfer, you can achieve a continuous change in transmission ratio, resulting in transmission and engine conditions of the most Good match

- Q: 22kw.2 pole fan can use Fuji inverter?

- Fan with Fuji? Money more people silly ... no comment ..

- Q: Laptop power adapter is used to do what

- Simply put the transfer into DC China's electricity is 220V AC, and the notebook is a direct current, the need for adapter to rectify, filter, regulator, and finally we need to form a direct current

Send your message to us

Variable Frequency Drive 11KV 2400KW VFD VSD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches