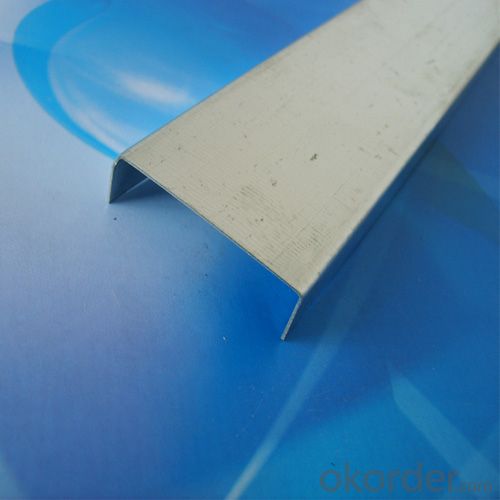

Used For Drywall/ Ceiling Designs/ Metal Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

Advantages and features:

1. Our products’ raw material is high quality hot dipped zinc galvanized steel strip, absolute fireproof and heat insulation, waterproof and antirust, anticorrosive , high durability

2.Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3. Double sized galvanization volume make sure that the plaster bone is corrupt and rust resistance.

4. Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

5.manufacture the special specification products for customers

6. High quality raw material guarantees the light steel keel of life and good performance of construction.

7. Possese own ten precision cold rolled steel strip production line.

Certificates

ISO 9001:2000 Quality management system.

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: How to install damping sound insulation felt

- 1, along the wall laying sound insulation felt, seam at the pressure seam processing; ???? 2, the installation of vibration keel, wedge around 600mm; keel gap filled with cotton; ???? 3, vibration-proof keel installed on the noise board (two-layer board clip insulation felt, sheet and sound insulation stitch treatment)

- Q: Light steel keel partition wall fire retardant coating shabu several surface

- Brush when, in accordance with the requirements, at least need to brush twice. Although the Tai Po people in practice only brush it again, but suggest that you still brush twice for safety.

- Q: Light steel keel wall circuit how to wear pipe

- Separate the laying of the wall: According to the architectural design, in the indoor floor of the floor wall and the edge of the line, and cited to the two main structure of the wall and the bottom of the floor, while pop the door and window hole line.

- Q: 4 m long prefabricated board can do light steel keel double gypsum board wall?

- Yes, because the prefabricated board toughness is better, and its specifications are not the kind of chunks, if the chunk can withstand the weight will be reduced in the middle of the possibility of falling to increase .. Light steel keel wall itself The weight is not heavy, coupled with the ceiling is also force, then the weight of the ground will be reduced accordingly

- Q: Light steel keel with what screws fixed gypsum board

- That is, depending on the general distance from the general self-tapping screw teeth to be larger. Fast teeth screws are generally used for wood, aluminum and other materials, in the role of power tools, you can quickly into the material inside their own. Because the fast tooth screws are mostly self-attack class, will not use the nut. Ordinary screw general mechanical screws, can support the nut. ??? Mechanical screws and self-tapping screws are very different in tooth pitch.

- Q: Can the gypsum board be painted on the wall

- You can play tuxedo on the keel on the line

- Q: How to fix the middle of the light steel keel to the roof and the ground, the keel has a joint?

- Keel fixation requires the use of expansion bolts fixed, but now many practices are directly linked with steel nails, so more convenient, the effect is almost, of course, is not good with expansion bolts. Top and bottom with 75 days keel. Then there are 75 vertical keels.

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- After the installation of the gypsum board, the paper gypsum board installation and the ground to stay in the gap, so as not to drag the ground to do when the tide back. If you consider the sound effects can be filled with sound-absorbing cotton, but the effect is not good. Really too loud, you can use cotton plug The

- Q: What is the pros and cons of a brick or a gypsum board?

- Wall, then the sound is very important, otherwise the side of the talk there all heard, this wall is very embarrassing. Light gypsum board, of course, can not be soundproof, the key is to choose the appropriate sound insulation cotton, and now people are more popular in the interior decoration is the gradient of sound-absorbing cotton, from environmental protection, fire, sound-absorbing efficiency and other considerations, gradient sound-absorbing cotton are present Home, office decoration more appropriate, such as the larger domestic conference center are using this sound insulation material.

- Q: Shanghai Light Steel keel ceiling Shanghai plant decoration office building decoration light steel keel ceiling wall

- Reasonable top design Also in the plant decoration should also pay attention to the top, the top of the plant is usually high, and most of them are steel frame, in the decoration of the top of the first design fire, ventilation, and the central air conditioning reasonable arrangements , Because these are plant decoration necessary hardware facilities, especially fire. The next is based on the use of the requirements to determine whether the ceiling of the problem, the plant ceiling a lot of material, if the beauty can be used for some mineral wool sound board, gypsum board, and other materials to do the top decoration, you can not do any ceiling, The top of the need to hide or not some of the facilities to do some local modification is also a modern minimalist design.

Send your message to us

Used For Drywall/ Ceiling Designs/ Metal Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords