Drywall Metal Stud for Australia And New Zealand

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

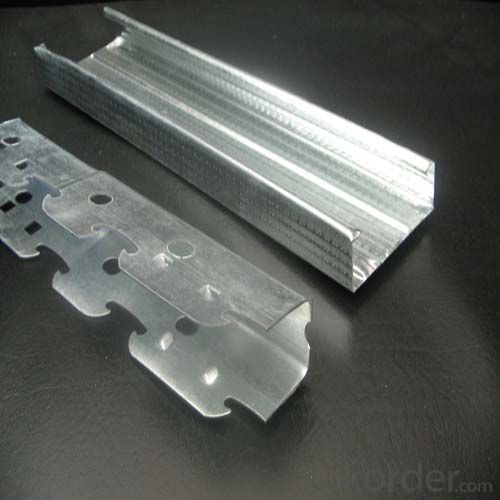

Australia drywall metal stud, drywall stud and track connection size:51/64/76/92/150mm ,thickness:0.55-1.15mm,galvanized z275g.

Australia metal drywall stud,1)Standard in Australia , 2)Thickness:0.5-1.5mm, 3)zinc coating:120-275g ,4)Very Perpendicular, 5)Support is fast construction, 6)Length size according to the customer size manufacture

Specification

PART NO | DESCRIPTION | Size(mm) | Length(mm) |

125 | 25mm Top Cross Rail | 25*21*0.55 | 3600/4800/6000 |

127 | 25mm Top Cross Rail | 25*21*0.75 | 3600/4800/6000 |

308 | 16mm Furring Channel Track | 16*20*30*0.55 | 3000 |

129 | 28mm Furring Channel Track | 28*20*30*0.55 | 3000 |

301 | 16mm Ceiling Batten | 36*16*0.5 | 4800/6000 |

303 | 22mm Cyclonic Ceiling Batten | 35*22*68*0.55 | 4800/6000 |

310 | 40mm Ceiling Batten | 35*40*70*0.55 | 4800/6000 |

308 | 16mm Furring Channel | 16*38*0.55 | 3000/3600/4800/6000 |

129 | 28mm Furring Channel | 28*38*0.55 | 3000/3600/4800/6000 |

401/489 | 51mm Stud | 51*33.5*35.5*0.55/0.75 | 2400/2700/3000/3600/4200/4800/6000 |

112/491/661 | 64mm Stud | 64*33.5*35.5*0.55/0.75/1.15 | 2400/2700/3000/3600/4200/4800/6000 |

403/493/671 | 76mm Stud | 76*33.5*35.5*0.55/0.75/1.15 | 2400/2700/3000/3600/4200/4800/6000 |

251/495/681 | 92mm Stud | 92*33.5*35.5*0.55/0.75/1.15 | 2400/2700/3000/3600/4200/4800/6000 |

511/691 | 150mm Stud | 150*33.5*35.5*0.75/1.15 | 3600/4800/6000/7200 |

400/490 | 51mm Track | 51 * 32/50 * 0.55/0.75 | 3000 |

111/492/660 | 64mm Track | 64 * 32/50 * 0.55/0.75/1.15 | 3000 |

402/494/670 | 76mm Track | 76 * 32/50 * 0.55/0.75/1.15 | 3000 |

250/496/680 | 92mm Track | 92 * 32/50 * 0.55/0.75/1.15 | 3000 |

510/690 | 150mm Track | 150 * 32/50 * 0.75/1.15 | 3000 |

Leg Stopping Angle 6mm | 30*6*0.4 | 3000 | |

P25 | Leg Stopping Angle 10mm | 30*10*0.4 | 3000 |

P26 | Leg Stopping Angle 13mm | 30*13*0.4 | 3000 |

P27 | Leg Stopping Angle 16mm | 30*16*0.4 | 3000 |

P01 | External Angle 90 | 30*30*0.4 | 2400/2700/3000/3600 |

P50 | Shadowline stopping angle | 10*10*30*0.4 | 3000 |

PART NO | DESCRIPTION | Thicknes |

Adjustable Direct Fix | 1.5mm | |

Beta Fix | Beta Fix | 1.5mm |

Long Beta Fix | Long Beta Fix | 1.5mm |

167 | Side mounted TCR Suspension Clip | 0.8mm |

139 | Locking Key | 0.7mm |

2534 | TCR Suspension Clip | 0.8mm |

121 | 5mm Rod Suspension | 5mm |

305 | Direct Fix Clip -150 long | 1.0mm |

314 | Direct Fix Clip-92 | 1.0mm |

247 | Right Angle Rod Bracket | 1.2mm |

274 | R0d Brackets | 1.2mm |

Ceiling Bracket | 1.6mm | |

Floor Pin | ||

239 | Direct Fixing Clips—Screw Fix | 1.2mm |

237 | Direct Fixing Clips-Concrete | 1.2mm |

394 | Direct Fixing Clips 175mm | 1.0mm |

226 | Direct Fixing Clips 75mm | 1.0mm |

SWC3 | Slotted Web Cleat | 3mm |

Product Overviews

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: What are the consequences of installing a hanging cabinet on gypsum board wall?

- Gypsum board can not load, do not install gypsum board door hanging cabinet. If the impact of drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon penetrate, But it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play wood slag to.

- Q: Home to decorate the ceiling, playing the wall, I learned from the market can be resistant, dragon card, Saint Gobanchenko these brands of light steel keel gypsum board which good point?

- You said these are very good brand, Saint-Gobain and Long card companies with more. The material is on the one hand, the ceiling is the most important woodworking craft and craftsmanship. Material is not a problem

- Q: Light steel keel should be how to strengthen, in order to make solid wood door installed more prison?

- Light steel keel wall strength regardless of Zeyang are a heart disease, if there is room, then the proposal is still good wall

- Q: Light steel keel wall waterproof

- The grass on the surface of the gray skin with a knife to remove, with a broom to dust, sand and other debris clean, especially the root, floor drain and drain and other parts to be carefully cleaned. If there is oil, apply wire brush and sandpaper brush off. The base surface must be flat, the depression should be filled with cement putty.

- Q: To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With C-beam or two angle steel, LI put two and wall fixed, the keel fixed to the LI. Do not be able to drill on the ground.

- Q: 4 m long prefabricated board can do light steel keel double gypsum board wall?

- Yes, because the prefabricated board toughness is better, and its specifications are not the kind of chunks, if the chunk can withstand the weight will be reduced in the middle of the possibility of falling to increase .. Light steel keel wall itself The weight is not heavy, coupled with the ceiling is also force, then the weight of the ground will be reduced accordingly

- Q: How to install light steel keel gypsum board wall

- Door and window frame according to the design position in place, with the vertical keel, along the ground, along the top keel connection. Wooden window frames can be fixed with wooden screws, steel, aluminum alloy door and window frames can be fixed with self-tapping screws.

- Q: Light steel keel gypsum board partition design should pay attention to what the problem

- Light steel keel is attached to the gypsum board, it can be seen, the installation of light steel keel spacing is based on the thickness of the gypsum board to decide. Like the 12mm gypsum board, its spacing is 450mm, according to the gypsum board to determine its spacing. Finally, in the adjustment of hanging pieces into the keel inside the appropriate rotation can be consistent.

- Q: Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Benzene board and extruded board can be, are more suitable for home improvement. I do with the noise is extruded board than the benzene board sound insulation is also very good environmental protection

- Q: What is the difference between gypsum board partitions and lightweight partitions?

- Gypsum board partition and lightweight partition the most important difference there are three points: First, the difference between the structure. Gypsum board is a skeleton-like partition, that is, to rely on the backbone of light steel keel can stand up, and light partition entirely by their own plate to cut off; Second, the difference between materials, gypsum board itself is only gypsum and pulp Composite products, and lightweight partition is made of sheet metal, wood chips, cement foam, additives, perlite composite wall;

Send your message to us

Drywall Metal Stud for Australia And New Zealand

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords