Reynolds Wrap Aluminum Foil Sheets - United States 3003 H14 H22 Aluminum Coil Manufacturers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

We are able to supply 1,2,3,5,6,8 series alloy coil, foil and sheets, including 1***, 3***, 3104, 5052, 5182, 5754, 5083,5086,8011,8079

Our products include:

1). Mill-finished aluminum coil:

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754, 5083,8011 ,8079etc.

Temper: H14/16/18/22/24/32, HO etc.

Thickness: 0.08mm—100mm

Width: 100mm—2200mm (Can be slitted)

Notice: Embossment can be done if required.

2). Color-Coated Aluminum Coil:

Alloy : AA1050/1100/3003/3005/3105/5005/5052/8079 etc.

Thickness: 0.03mm—1.50mm

Width: 10mm—1600mm (Can be slitted)

Coating : PVDF, PE

Coating thickness: Usually 16-25 micron, could be33-40 micron

Color : According to customers’ requirements

Notice : Embossment can be done if required

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

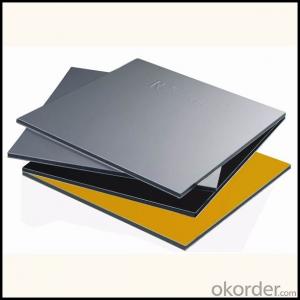

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc |

- Q: Are aluminum sheets available in different colors?

- Yes, aluminum sheets are available in different colors. They can be coated or painted in various shades to suit different aesthetic preferences and design requirements. The color options range from traditional metallic finishes like silver and gold to a wide array of vibrant and contemporary colors. The availability of different colors allows aluminum sheets to be used in diverse applications such as architectural cladding, signage, automotive industry, and home décor. Additionally, the color coating or paint on aluminum sheets also provides additional protection against corrosion and enhances their durability.

- Q: how many aluminum ions are present?how many chloride ions are present?what is the mass in grams of one molecule of aluminum chloride?help! i have no clue how to do this i need to know how for my quiz!!!

- You have to remember Avogadro's number: 6.02 x 10^23 Read about it in your text book. It is the number of molecules of any atom that make up 1 mole. 1 mole of a molecule is equal to it's atomic weight in grams. So, the atomic weight of aluminum is 26.9. So, 26.9 grams of aluminum contains exactly 6.02 x 10^23 molecules of aluminum (or 1 mole). What's the molecular weight of aluminum chloride? Well, 26.9 + 3(35.5) = 133.4 the 35.5 is the molecular weight of chloride and there are 3 of them. So, 133.4 grams of aluminum chloride would be 6.02 x 10^23 molecules. We only have 37.2 g. 37.2 g/ 133.4 g per mole = 0.279 moles. 0.279 moles x (6.02 x 10^23 molecules/mole) = 1.68 x 10^23 molecules of aluminum chloride. So, since there is one aluminum per molecule, you have your answer. Just multiply by three to find out how many molecules of chloride are present. Finally, if 133.4g = 6.02 x 10^23 molecules, then 1 molecule = 133.4 / 6.02x10^23 = 22.16 x 10^-23 or 2.216 x 10^-22 Make sure that the periodic table you use for class has the same values (some tables are more simplified then others). Also, make sure that you use the correct number of scientific digits when calculating your answer.

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces. Aluminum is known for its high reflectivity, making it a popular choice for various applications that require reflective surfaces. Aluminum sheets can be polished to a high shine, allowing them to reflect light and create a mirrored effect. This makes them ideal for uses such as reflectors in lighting fixtures, solar panels, mirrors, and decorative purposes. Additionally, aluminum's reflective properties make it suitable for applications where heat reflection is required, such as in thermal insulation or roofing materials. Overall, aluminum sheets are a versatile and effective option for creating reflective surfaces.

- Q: What are the acoustic properties of aluminum sheets?

- Aluminum sheets have relatively low acoustic absorption and transmission properties, making them reflect sound waves rather than absorbing or transmitting them.

- Q: is there any kind of deoderant, other than those crystals that smell, that don't have aluminum in it?

- Funny you should ask...I was reading the labels just yesterday on my deods also! Old Spice has Alum Hydroxide...Brut has Popylene Glycol and Old Spice High Endurance has Dipropylene Glycol. Ususally the 1st ingredient that you read on the label tells what it is the main ingredient. I prefer Brut!

- Q: Can the aluminum sheets be used for printing applications?

- Yes, aluminum sheets can be used for printing applications.

- Q: What types of aluminum sheets are recommended for outdoor applications due to their durability and resistance to weather conditions?

- <p>Yes, there are specific types of aluminum sheets designed for outdoor use. Marine-grade aluminum sheets, such as 5083 or 5086 alloys, are highly resistant to corrosion and are ideal for marine applications. Aluminum sheets with a protective coating, like anodized aluminum or those with a fluoropolymer finish, offer excellent weather resistance and durability. Additionally, aluminum sheets with a mill finish or those coated with a clear coating can also be suitable for outdoor use due to their resistance to UV rays and ability to withstand temperature fluctuations.</p>

- Q: What is the reflectivity of aluminum sheets?

- The reflectivity of aluminum sheets is quite high, typically ranging from 80% to 90%. This high reflectivity is due to the smooth surface and the unique properties of aluminum, which allow it to efficiently reflect light and other electromagnetic waves. This makes aluminum sheets commonly used in applications where high reflectivity is desired, such as in the construction of reflective surfaces, solar panels, and mirrors. Additionally, the reflectivity of aluminum can be further enhanced by applying a reflective coating or polishing the surface.

- Q: Are aluminum sheets suitable for storage tanks?

- Yes, aluminum sheets are suitable for storage tanks.

- Q: I know 7005 series aluminum is stronger and lighter than 6061series, but how does 7005 compare to 2014 series?

- i okorder

Send your message to us

Reynolds Wrap Aluminum Foil Sheets - United States 3003 H14 H22 Aluminum Coil Manufacturers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords