Raw Materials for Refractory:Under 325 Mesh Calcined Alumina Powder Al2O3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Under 325 Mesh Calcined Alumina Powder AL2O3

The main material of our refractory castable high alumina powder is Al2O3—SiC—C, there’s 2 types including baking casting material and free baking material, the width of iron runner is required above 2.4 meter, the depth is above 1.7 meter,it has a good performance in site operation, with easy repair, tapping iron is allowed after pouring finished. Although the invest is more higher for once time, but it will be with a longer service life and a few mending work. Refractory castable is the production and the most widely used a monolithic refractories.

Application:

It can be used to formulate unshape refractory material; expansive cement, self-stressing cement, addition material of chemical construction material and projects with special requirements.

aluminum oxide property:

It has higher hardness and slight lower toughness comparing with brown fused alumina. It is also characterized by its high purity, ability of self-sharpening, better cutting, less heat emit, higher efficiency, acid and alkali resistance, good thermal stability. As the abrasive materials, it is suitable for grinding high-speed, high carbon steel, as loose grains, it widely used for bonded and coated abrasives , polishing, precision casting and so on .

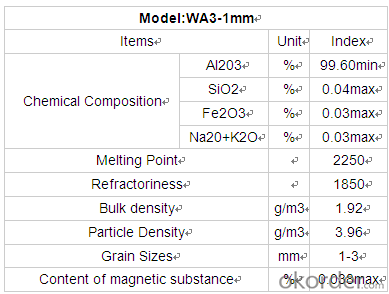

white fused alumina grits&powder chemical composition

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q: What are the materials of insulation firebricks?

- The furnaces of firebricks are generally divided into two types, namely, unshaped refractory materials and shaped refractory materials. Unshaped refractory materials, also called castables, is a mix of powdery particles of many aggregates and one or multiple adhesives. They must be stirred well with one or multiple liquids when in use, which has a strong liquidity. Unshaped refractory materials generally refers to firebricks. They have standard rules about their shapes and can also be processed temporarily as needed.

- Q: How long can gypsum board endure fire?

- Fire endurance refers to the fire-resistent limit of the whole system of light-gauge steel structure coupled with gypsum. It does nor merely refers to gypsum board. Fire endurance of the common gypsum board with the thickness of 9.5mm keeps 1.5 hours. Those gypsum board with the thickness of 12mm has a fire endurance of 3 hours.

- Q: Who knows the model of fireproofing materials?

- Models of fireproofing material: PC 6555 Bayer 6555 fireproofing PC 6557 Bayer 6557 fireproofing PC 6485 Bayer 6485 fireproofing PC 6385 Bayer 6385 fireproofing PC 6265 Bayer 6265 fireproofing PC 2865 Bayer 2865 fireproofing PC 4610 Dow 4610. Hope my answer will be helpful to you!

- Q: What are the construction measures of refractory material in winter? Please descriptive briefly.

- The temperature is low in winter, so refractory bulk materials should be stirred evenly on time to avoid freezing.

- Q: The difference between refractory and thermal insulation material

- In simple terms, refractoriness is different. The refractoriness of refractory is high while that of insulation material is low.

- Q: What needs to be noted when choosing and using blast furnace fireproof materials? Who knows?

- there are different temperatures in various parts of the blast furnace, thus using different types of refractory.

- Q: What's the B grade fireproofing material?

- Grade B: rubber and plastic, extrusion molding, polyphenyl, PEF. organics, extruded sheet, polyphenyl board, phenolic resin. Hairong modules (thermal insulating and fireproof material) can reach grade B1 in fireproof performance.

- Q: How many fire endurance grades are the AAA fire resisting shutter divided?

- The fire shutter is divided into A / B / C classes. The refractory limits are not less than 1.2 /0.9 /0.6 hours. References to "general technical specification for steel fire resistance rolling shutter door GB 14102-93". 4.3 4.3.1 Classification according to fire resistance time. The common steel fire resisting shutter(see Table 3) The categories of the codes of the refractory time hF1 1.5F2 2.04.3.2 composite steel fire shutter composite steel fire shutter(see Table 4). Table 4 and Category Code refractory time hF3 2.5F4 3.04.4 refractory press time, smoke performance classification 4.4.1 ordinary steel fire anti-cigarette curtain (see Table 5) Table 5 and category code leak smoke refractory time h (20Pa pressure) FY1 1.5 ≤0.2m3 / m minFY2 2.0 ≤0.2m3 / m min4.4.2 composite steel fire anti-cigarette curtain (see table 6) table 6 and category code leak smoke refractory time h (20Pa pressure) FY3 2.5 ≤0.2m3 / m minFY4 3.0 ≤0.2m3 / m min excerpt complete fire shutter when the fire district for fire resistance of 3 hours, the opening portion on the firewall setting fire shutter fire resistance of 1.2 hours. **** Fire resistance of 3.0 hours called premium (fire back surface). "Construction Regulation" is mentioned in setting up a firewall and used as the separation of the fire resisting shutter and the fire?compartments. When taking the fire back surface temperature rise as the fire resistance standard of the fire resisting shutter, the fire endurance should not be less than 3.00h; When taking the fire back surface temperature rise as the fire resistance standard of the fire resisting shutter, the two sides of the roll should have protection of ?closed automatic water spray system, and the duration of water spray system should not less than 3.00h. In summary: The fire resisting shutter can be divided into: Grade, A, B and C looking to adopt

- Q: I wanna ask about the thermal insulation material fire resistant level?

- The inorganic glass wool, rock wool and foam glass. Organic: The best is the phenolic foam, phenolic foam composite cement layer is level A.

Send your message to us

Raw Materials for Refractory:Under 325 Mesh Calcined Alumina Powder Al2O3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords