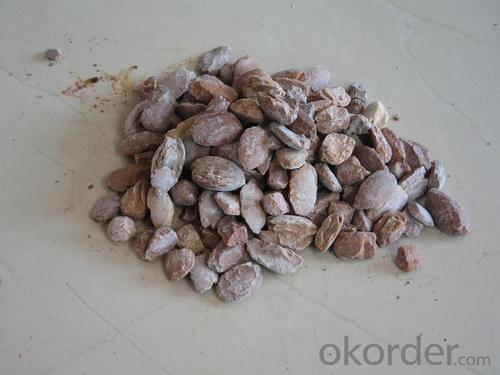

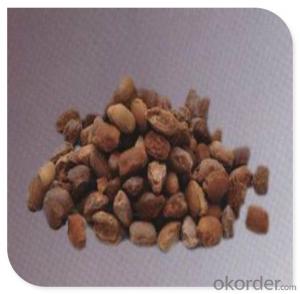

Raw Materials for Refractory:Dead Burnt Magnesite / DBM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Dead Burnt Magnesite (DBM):

Dead Burnt Magnesite is selected from natural magnesite, calcined temperature and the shaft kiln. It is the material of ordinary magnesia bricks, shaped and unshaped refractory products.

Specifications of Dead Burnt Magnesite (DBM):

Specification(%) | ||||||

Brand |

MgO min. |

LOI max. |

SiO2 max. |

CaO max. |

Fe2O3+Al2O3 max. |

B.D.G/cm3 min. |

DBM90 |

90.00 |

1.00 |

4.50 |

2.50 |

3.00 |

3.1 |

DBM-95 |

95.00 |

0.30 |

3.00 |

2.00 |

1.30 |

3.15 |

DBM-97 |

97.00 |

0.20 |

0.7 |

1.3 |

0.90 |

3.25 |

DBM-972 |

97.2 |

0.2 |

0.6 |

1.3 |

0.9 |

3.27 |

DBM975 |

97.5 |

0.1 |

0.6 |

1.2 |

0.8 |

3.28 |

Packaging & Delivery of Dead Burnt Magnesite / DBM:

Packaging details:1mt big bag or according to customers’ requirements

Delivery:7-15 work days after the order is confirmed

Applications:

1.Mainly used in processing raw materials of different magnesia refractory,

2. the production of steel lining the bottom and ramming mixes;

3. the raw materials of magnesia brick and magnesia-chrome brick;

4.used electric steel making furnace, heating furnace, non-ferrous metals blowing converter furnace the bottom and the lining of the refractory materials.

Advantages

1.We can control the quality and cost due to our strong capacity and cash flow in China .

2. We have strict and mature quality and logistics control on the cargo .

3.As a governmental company, we are reliable.

- Q: what is the grading standards of external wall thermal insulation materials?

- What is the grading standards of external wall thermal insulation materials? summarizing the three versions of GB8624 (1997,2006,2011) external wall insulation fire rating can be basically divided into: A1, A2, B1, B2, B3 and other levels. the dividing is based on many technical indicators. It takes time to explain for It is professional and technical. For details, please contact Qingdao Shan Textile Instrument. they specialized in external wall insulation fire rating tester.

- Q: How to prolong the furnace age of Induction furnace by using fireproof materials?

- magnesia solid materials have thermal endurance and erosion/ performance and its change of temperature is likely to cause cracks. properties of materials (aluminum) in such case have to be taken into consideration.

- Q: What are grade classifications of the external walls for fireproofing?

- The basic level can be divided into: A1, A2, B1, B2, B3 and other levels. There are many technical indicators to make specific division, but I partly cannot report for a while, because it is very professional and technical. Please contact Qingdao Shanfang Instrument Co., LTD for details, they specialized in the external wall thermal insulation materials fire?rating testers.

- Q: What are the differences between intensive refractory busway and other busways?

- Compact busway is named according to its structure, and fire-resistant busway is named after its uses. Compact busway especially refers to busway which is closely laminated between phases and between phase and shell, and use thin insulating material to achieve the insulation result. suitable for power supply system of alternating current three-phase four-wire, three-phase five-wire system, frequency of 50 ~ 60Hz, rated voltage up to 690V, rated operational current of 250 ~ 5000A, as auxiliary equipment for mining, enterprises and high-rise buildings, and especially suitable for the transformation of workshop and old enterprises. Fire-resistant busway is composed of shell coated with fire retardant paint, bus line wrapped with fire-resistant mica tape and bracket made by refractory insulating material. Bracket has a plurality of grooves where inbedding the bus line and fixed it. There is a busway connecting box at one end of the busway and there is a bus line splitter box in the busway. Fire-resistant busway has excellent insulation properties, which can not only be used continuously in a normal environment, but also can be used in the fire environment continuously for more than one hour, suitable for high-rise buildings and important facilities, replacing the fire-resistant cables to transmit and distribute power .

- Q: What crusher is used for raw material of broken refractory material? What is the rough crushing process? What are the materials? Thank you!

- Now cone crusher is generally used.

- Q: What are the best refractory materials in 2,400 Celsius degree?

- You can try zircon sand which has a melting point of 2430.

- Q: how long is the fire endurance of plasterboard?

- fireproof endurance can reach a maximum of 4hours, suitable for a variety of public buildings firewall, and partitions for public exit passageway, reaching standard level of fireproof. the lightweight partition made of gypsum board and steel stud is mainly for dividing architecture space. Rock wool can be filled in the mddle according to its design requirements, using different series of gypsum board, steel stud. the walls may have fire resistance and sound insulation property of various degrees.

- Q: Who knows what kind of fire protection material is better?

- Characteristic of polyurethane rigid foam thermal insulation decorative composite board: (1) ultra high cost performance, increased property's selling point (high cost performance) new model of thermal insulation material, excellent thermal insulation properties, elegant decorative effect, 50 years of service life, reduce maintenance costs and social waste. (2) it overcomes defects of traditional insulation technology (to solve the freezing and thawing, veneer cracking and shedding) traditional benzene board, the phenomenon of freezing and thawing that is easily appear in plastic extruded sheet, paint finish is easy to crack; its veneer facing can easily fall off; thermal insulation materials and wall are poorly adhered, easy off the whole. There is a themal bridge in dry hanging wall. (the characteristics of polyurethane composite board)

- Q: What is glass furnace used high-grade refractory materials?

- It is said that building a furnace need 30 million? After the ignition, it can't be gone out. Only at the waste to maintenance?

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Raw Materials for Refractory:Dead Burnt Magnesite / DBM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords