Raw Materials for Refractory:Fine and High Purity Calcined Alumina Powder Al2O3 for Ceramic, Refractory, Glaze, Metallurgy

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

fine and high purity calcined alumina powder with 99.5% al2o3 for ceramic,refractory,glaze,Metallurgy

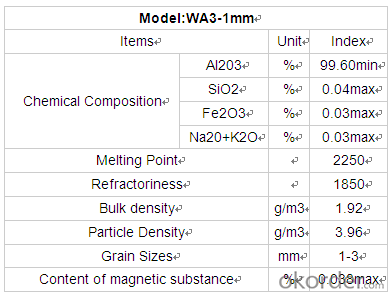

Specification:

High purity AL2O3 Aluminum Oxide/ Aluminum powder

Manufacturer

Superfine

Application of AL2O3

*Wear resistant ceramic, electronic ceramics, small ceramic parts.

*Refractory- - Shaped refractory (firebrick etc) & Unshaped refractory (castable etc)

*glaze series.

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q: what's the seal of fireproofing material?

- Folded organic putty takes organic material as bond,it has certain flexibility or plasticity while using, and it's products are thick liquid or cement shaped object. Folded WXY-II is powered?solid that takes inorganic materials as main components, it has certain workability while used with admixture. Folded fire retardant bag is the packaged object made by fireproofing material, and it's suitable for fireproofing seal of larger openings or fire separation of cable?bridge(fire retardant bag also refers to fireproof bag) Folded fire retardant module is the solid made by fireproofing material with certain shape and size, and it is easy for cutting and drilling, suitable for fireproofing seal of opening and cable?bridge. Folded seal board is made by fireproofing material, it's easy for cutting and drilling, suitable for fireproofing seal of large opening. Folded foam seal is a kind of fireproofing material that can automatically expand and foam and sealed by opening after injecting the foam into opening. Folded sealing strip is a product or flexibility coiled material mede by fireproofing material with certain geometry shape. Folded sealing gum is a kind of liquid fireproofing material that has a function of fireproofing and sealing. Folded fire retardant bag is soft and windable tape-shaped product made by fireproofing material, it is winded on the external surface of plastic pipe and fixed with steel belt or other proper methods, it's the expansion, squeezing and softening pipe after contacting with fire, opening left by burning or soften of seal plastic pipe. Folded fire retardant ring is the product made by fireproofing material and metal shell, it's covered on the external surface of the plastic pipe, expanding and sealing after contacing with open fire, the opening left by burning and soften of plastic pipe when it passes through the opening of wall and floor.

- Q: Can anyone tell me what is A-leve fireproof material?

- Combustion performance of materials can be divided into: A-level, B1-level, B2-level and B3-level, which respectively refer to noncombustible, difficult-flammble, flammable and inflammable materials. Building materials can be divided into four grades based on combustion performance (noninflammability, flame retardancy, flammability and inflammability). According to the stipulation of "Specification of Fireproof Design for Buildings" (GBJ16-1987) (2001 revised edition), fire hazard of production or storage should be divided into A-level, B-level, C-level, D-level and E-level. In "Specifications on Fireproof Design for Petrochemical Enterprises" (GB50160--1992) (1999 Revision), it also stipulates that fire hazard should be classified on the same basis of subtsance danger in usage, production or storage. According to different fire hazard, requirements and measures of oreventing and restricting fire explosion can be put forward from the aspects of fire?separation distance, fire resistant rating of buildings, allowed floors, safe evacuation, fire fighting facilities and other aspects.

- Q: How to divide the materials according to the National Fireproofing Material Standard?

- according to China's national standard GB8624-97, the combustion performance of construction materials can be divided into several classes: Class A: Incombustible building material: Almost no burning material. Class B1: nonflammable building material: nonflammable material has a good flame resistance effect. when it meet the open fire in the air or burnd at high temperature, it is difficult to spread quickly, and when the fire source is removed, the combustion stop immediately. Class B2: flammable building material: flammable material has a good flame resistance effect. when it meets open fire in the air or at high temperature, it will immediately burst into flames and easily cause fire spread, such as wooden column, timber roof truss, timber beam, and wooden stairs,ect.. Class B3: inflammable building material: No flame resisting effects, highly flammable, high fire risk.

- Q: How long is the fire-fighting time of A class fire resisting window?

- Fire resisting window' duration of fire resistance: A class window, fire insulation ≥1.50h and fire resistance integrity ≥1.50h. Fire resisting window can be divided into three kinds: 一. window frame and sash framework adopt fire resisting window with steel manufacture ; 二. window frame and sash framework adopt fire resisting window with wooden manufacture; 三. window frame adopt steel and sash adopt wooden material or window frame adopt wooden material and sash framework adopt fire resisting window with steel material.

- Q: Development trend of refractories

- Mullite Matrix clinker. There are higher requirements of kaolin and refractory annded life, it should be able to grind medical industrial raw materials alumina, vacuum extrusion molding, high temperature roasting and smelting from unshaped refractory material a good thermal mechanical properties in the kiln and has good application prospect; 2, Dong Qingshi clinker. With kaolin and magnesia as raw materials, wet grinding, vacuum extrusion, and then high temperature calcination, furniture has a very good prospect; 3, magnesium calcium sand. Because of the development of clean steel, low carbon steel, high oxygen steel and stainless steel, the basic importance of free calcium oxide refractories is supported; 4, fused eutectic composite. Bauxite based fused corundum, bauxite based fused mullite, bauxite based fused mullite zirconia, fused corundum zirconia fused zirconia, Magnesium Oxide and other materials have been developing rapidly; 5, high density spherical hollow mullite aggregate. The wall thickness of the shell of the 0.2 - 1.5 - 5 mm, diameter 40 mm, smooth surface, can not be uniform, spherical shell, this may be a double, a prominent part of the surface can be dense, can also be used for hollow casting material, not only can improve the insulation performance of the material, in order to reduce the volume density. Instead of destroying its strength.

- Q: Does the production of refractory belong to advanced technology?

- Refractory is traditional ceramic material. We can only say that national development is relatively backward. If the refractory is counted as new material, then it still has huge development potential.

- Q: How long does it take for refractory cement to solidify?

- 1. First you should be aware of the concepts of condensation and condesation time. Refractory cement belongs unshaped refractories, which when added water or liquid binding agent to mix, the agitation material will gradually lose thixotropy or plasticity and become in a state of solidification, thus is solidified. The time needed to finish the process is called solidification time. The whole process is divided into initial and final set. When beginning to lose plasticity called the initial setting, when called plasticity completely lost the final setting. 2. For refractory cement, the solidification time depends on the matching of the material and the parts and using methods. Under normal circumstances, in order to meet the requirements of time of construction, the initial set time should be no shorter than 40min, and the final set time should be no longer than 8H 3. There are also some exceptions. When refractory cement is used for spraying and injection operation together with other refractory castable, the set time is required as short as possible, sometimes flash set is required to prevent the occurrence of peeling or collapse of the spraying layer.

- Q: How to make use of waste refractory materials whose main elements are alumina and mullite?

- Crushing and pressing refractory bricks, or refractory parts . Such as welding positioner tracks use disposable tools.

- Q: Which are roofing fireproofing material?

- (1) Foamed concrete is a kind of fire-proof thermal inuslation matertial featured by good fire resistance and thermal insulation. Besides, it is also characterized by excellent sound proofing, penetration resistance, easy construction, safety and environmental protection without toxin and pollution. (2) Foam glass is featured by light weight, small heat conductivity coefficient and water absorbption, non-inflammability, fire resistance, high strength, no moulding, corrosion resistance, non-toxin and stable physical and chemical properties and thus widely used petroleum, chemical engineering and underground construction. It is also featured by thermal insualtion, heat/cold preservation and sound absorbption and thus can be used for thermal insulation of external wall and roof of civil builduing. Foam glass is featured by stable chemical property, easy to be processed and not easy to deforme, and durable. (3) With slag, basalt and other natural ore as the main raw material, rock wool, mineral wool and its products are made by high temperature melting into fiber, and then processing with binder. It has low thermal conductivity, fire resistance, easy construction and good effects of energy saving and thus is highly cost-effective. (4) With phenolic foam material as main material, phenolic resin plate is made by foaming thermoset phenolic resin. It is featured by light weight, fire resistance, no burning in the air, no smoking, non-toxin, no dropping and non-embrittlement and thus is an ideal thermal insulation material used in HAVC projects. Due to its high obturator formamen rate, low heat conductivity coefficient, good thermal insulation, water resistance and water vapor permeability, phenolic foam is an ideal thermal insulation material.

- Q: What are the main materials in concrete fireproofing material?

- fireproofing materials mainly consist of class A incombustible?material and class B1 nonflammable material. Class A incombustible?material: Granite, marble, terrazzo, cement products, concrete products, gypsum board, lime products, clay products, glass, tiles, mosaics, steel, aluminum, copper alloy; class B1 nonflammable material: Ceiling materials, dry wall, fibrous plaster.

Send your message to us

Raw Materials for Refractory:Fine and High Purity Calcined Alumina Powder Al2O3 for Ceramic, Refractory, Glaze, Metallurgy

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords