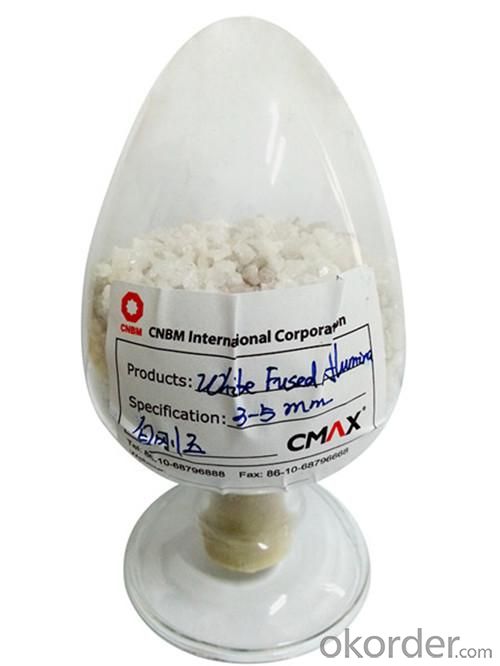

Raw Materials for Refractory:White Fused Alumina for Abrasive

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of White Fused Alumina For Abrasive:

Place of Origin:China mainland

Material:Aluminum oxide

Shape:Block

Color:White

Specifications of White Fused Alumina For Abrasive:

|

Al2O3 |

Fe2O3 |

SI020 |

Na2O |

|

99.20% MIN |

0.10% MAX |

0.20% MAX |

0.30% MAX |

Packaging & Delivery of White Fused Alumina For Abrasive:

Packaging details:1mt big bag or according to customers’ requirements

Delivery:7-15 work days after the order is confirmed

Applications:

-Blast-cleaning

-Roughening

-Grinding, lapping and polishing media

-Reusable abrasive

-Ceramic grinding wheels and grinding media

-Wear-resistant and refractory products

Advantages

1.We can control the quality and cost due to our strong capacity and cash flow in China .

2. We have strict and mature quality and logistics control on the cargo .

3.As a governmental company, we are reliable.

- Q: How many kinds of refractory materials are there in the EI?

- I suggest that you contribute articles to foreign SCI journals for the odds are better, and generally the articles that fill the bill will not be rejected. The traditional refractory materials can contribute to EI journal. If being rejected by EI journal, you can also contribute to Russia's journal Industrial Ceramics and Refractories. I didn't contribute to the Journal of Wuhan University of Science and Technology, the receiving cycle is almost 3 to 4 months. Though the impact factor is low, domestic EI journal is not so good, it is still SCI journal. This is my own experience, please take my advice. The best journals are the Journal of the American Ceramic Society and the Journal of the European Ceramic Society, I heard that they are not bad. But the best domestic EI refractory material journal is the Journal of The Chinese Ceramic Society. It is very long, but if it belongs to your university, it is another pair of shoes. Journals now all want to have materials about functional ceramics, and they don't want Chinese articles, if your English is not well enough, you can choose Ceramics International and Japan Ceramics but they have strict manuscripts reviewing standards.

- Q: How to divide the fire resistant level of EVB?

- 1. The thermal insulation material of level A combustion performance: Inorganic fiber spray coating, glass wool, foam glass, foamed ceramics, rock wool, foam cement and hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. I hope I can help you!

- Q: who knows the fire resistant levels of fireproofing glass?

- Fireproofing glass is a kind of special glass which can keep its integrity and thermal insulation performance in regular insulating refractory trials. and it can be divided into three classes according to its fire resistance: Class A, it's a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. This kind of glass has the properiyies of transmittance, fireproofing ( smoke insulation, fireproofing, and keeping out thermal radiation), sound insulation, shock resistance, and it's suitable for steel and wooden fire door of building decoration, windows, varnishing, partition walldaylighting?roof,ceiling?screen,perspective floor and other construction components demading for transparency and fireproofing. Class B, it's a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. Such kind of fireproofing glasses mostly are composite fireproofing glasses and has characteristics of transmittance,fireproofing and smoke insulation. Class C, it's a kind of fireproofing glass that only satisfies the requirements of refractory integrity. This kind of glass has characteristics of transmittance, fireproofing, smoke insulation and high strength,etc. It's suitable for fireproofing glass partition wall, fire Windows, outside curtain wall and other places without insulation requirements. Classify from the structure,fireproofing glass can be divided into composite fireproofing glass and monolithic fireproofing glass.

- Q: What are the meanings of azs, 34% and ec in fused brick?

- The fused brick, also called zircon corundum brick, is shorted as AZS for three chemical components in Al2O3-ZrO2-SiO2 ternary diagram. I don't know the meaning of EC.

- Q: What is the difference in the nature between the refractory material and thermal?insulation?material

- thermal?insulation?material is used to thermal insulation and the transfer of heat insulation. refractory material is defined as greater than 1580 ° non-metallic materials, such as calcium silicate board. its using temperature can reach to 1100 degrees, and some can also be used at high temperatures, and all high-temperature industrial can't be oprated without it, and the using temperature of polycrystalline alumina fibers can reach to 1800 degrees

- Q: Is there requirement for radiation indicator in refractory?

- All refractories have no radiated harm to environment, so there is no requirement. From the elemental analysis, magnesite. I do not know it is helpful to you. But for refractory rwa material, any chemical element is radiated, including silicon?dioxide; If they are radioactive. From the use analysis, such as bauxite, do not have use value.

- Q: Can I use ordinary cement with the addition of sand, clay, and salt as refractory material to paste the stove?

- Add some hair and slags, or it will crack before calcination.

- Q: What material is used to make furnace pipe of refractory bricks?

- Furnace pipe of refractory brick is an indispensable part of casting cupola. Furnace pipe is divided into upper and lower part. Radial direction and axial breathing. The upper furnace pipe adopts double layer steel structure and countercurrent air supply mode. The lower furnace pipe is made by processing integrated heat resistant steel in flange, fin and inner wall in wearing parts. The operation life is over 3000h. There is radiating rib of heating air on the edge of furnace pipe liner by using the heat of casting cupola to heat air in cupola. Hot air temperature is about 180-250℃, which contributes to improve trhe thermal efficiency of production equipment, decrease production cost and improve economic benefit of enterprises.

- Q: Can anyone say something about what A-level fire-proof decorative material is?

- Combustion performance rates of decoration materials ratess combustion performance of decoration materials A incombustible B1 flame retardancy B2 flammability B3 high flammability The B1 rate combustion performance of gypsum plaster board and mineral wool acoustic panel absorber installed on steel joist can be used as A-level decoration materials. Inorganic decorative coating applied on the A level substrate can be used as A level decoration materials. Hope you adopt

- Q: What kind of foundry ingot refractory materials are there? Please be more detailed.

- Classification of refractory materials used in foundry smelting process: refractory brick, siliceous brick, high alumina brick, corundum brick, magnesia brick, magnesia brick, magnesia carbon brick. Unshaped refractory materials: ramming material, castable, refractory cement, silica, magnesia, etc.

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Raw Materials for Refractory:White Fused Alumina for Abrasive

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords