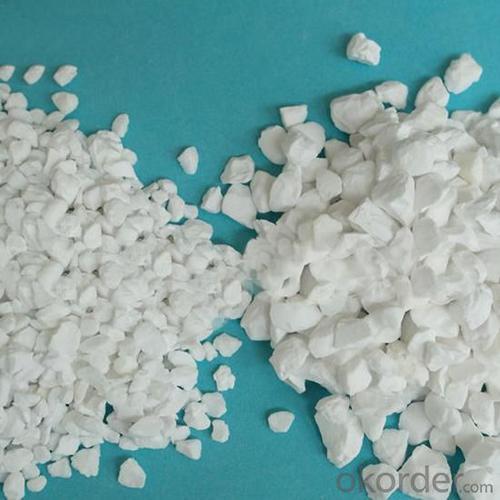

Sintered Tabular alumina

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Metric Ton/Metric Tons m.t.

- Supply Capability:

- 2000 Metric Ton/Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Sintered Tabular alumina:

Place of Origin:China mainland

Material:Alumina Cement

Particle Shape:Block/Ball/Grain/Powder

Al2O3 Content(%):99.5%

SiO2 Content(%):0.02%

Color:White

Specifications of Sintered Tabular alumina:

|

Shape |

Type |

Chemical Compositon |

Physical Characteristics | |||||||

|

Al2O3 |

Na2O |

SiO2 |

Fe2O3 |

Bulk Density |

Apparent Porosity |

Water Absorption |

Packed Bulk Density |

Cold Crushing Strength | ||

|

≥% |

≤% |

≤% |

≤% |

≥g/cm3 |

% |

% |

Kg/m3 |

N | ||

|

Ball |

RP-T162 |

99.7 |

0.20 |

0.02 |

0.02 |

3.65 |

1.5 |

0.4 |

2160-2000 |

2900-14700 |

|

RP-T164 |

99.5 |

0.30 |

0.04 |

0.03 |

3.55 |

3.5 |

0.8 |

2000-1860 |

2700-13500 | |

|

RP-T60 |

99.3 |

0.40 |

0.09 |

0.02 |

3.50 |

5 |

1.5 |

|||

|

RP-T61 |

99.1 |

0.40 |

0.13 |

0.03 |

3.45 |

6 |

2.0 | |||

|

Granule |

RP-T60G |

99.3 |

0.40 |

0.10 |

0.02 |

3.50 |

5 |

1.5 |

(mm) 5-10 3-6 3-1 1-0 0.5-1 0.2-0.6 | |

|

RP-T61G |

99.1 |

0.40 |

0.13 |

0.03 |

3.45 |

6 |

2.0 | |||

|

Micro Powder |

RP-T60P45 |

99.2 |

0.40 |

0.09 |

0.02 |

3.50 |

5 |

1.5 |

(μm) -45μm (-325mesh) -20μm (-635mesh) | |

|

RP-T60P20 |

99.1 |

0.40 |

0.15 |

0.04 |

3.50 |

5 |

1.5 | |||

|

RP-T61P45 |

99.1 |

0.40 |

0.12 |

0.03 |

3.45 |

5 |

1.5 | |||

|

RP-Y61P20 |

99.0 |

0.40 |

0.15 |

0.04 |

3.45 |

5 |

1.5 | |||

Packaging & Delivery of Sintered Tabular alumina:

Packaging details:1mt big bag or according to customers’ requirements

Delivery:7-15 work days after the order is confirmed

Application:

Widely used in iron and steel industry

Primary choice of refractory aggregate

Foundry, petrochemical, ceramic and incineration

Competitive Advantages:

High purity

High refractoriness

High volume stability

High density, low permeability

High thermal shock resistance

High chemical resistance

High mechanical stability

High wear-resistance

Timely delivery & service

Good company reputation

- Q: What are the use of fire-resistant material and admixture?

- I am engaged in admixture and thus familiar. Welcome to exchange!

- Q: How long does it take for refractory cement to solidify?

- 1. First you should be aware of the concepts of condensation and condesation time. Refractory cement belongs unshaped refractories, which when added water or liquid binding agent to mix, the agitation material will gradually lose thixotropy or plasticity and become in a state of solidification, thus is solidified. The time needed to finish the process is called solidification time. The whole process is divided into initial and final set. When beginning to lose plasticity called the initial setting, when called plasticity completely lost the final setting. 2. For refractory cement, the solidification time depends on the matching of the material and the parts and using methods. Under normal circumstances, in order to meet the requirements of time of construction, the initial set time should be no shorter than 40min, and the final set time should be no longer than 8H 3. There are also some exceptions. When refractory cement is used for spraying and injection operation together with other refractory castable, the set time is required as short as possible, sometimes flash set is required to prevent the occurrence of peeling or collapse of the spraying layer.

- Q: What are the basic requirements of continuous casting for molten steel? What are the requirements for refractory materials?

- Refractories for continuous casting is an important part of the continuous casting machine, in addition to the characteristics of general refractory material, also for the purification of molten steel and improve the steel quality, stable molten steel temperature and composition, control and regulate the flow of the molten steel and other functions, so it is called functional refractories. The above is provided by the China Technology Department

- Q: What's the heat conductivity coefficient of fire-resistant material?

- The heat conductivity coefficient of fire resistant material is related to bulk density and mainly related to the internal structure. Different materials have different structure and thermal conductivity and temperature . Carbonaceous material can be used for heat dissipation and reach more than 15. For thermal insulation it can be 0.00.

- Q: What is the type of heat resistance property of high temperature electric furnace ?

- According to the levels of refractoriness : Common refractories: & Gt: 1580 ℃ ~ 1770 ℃ advanced refractories: 1770 ℃ ~ 2000 ℃ AAA refractories; 2000 ℃

- Q: What kind of material is refractory bauxite?

- Refractory bauxite, also known as bauxite alumina or bauxite with high alumina, is the main raw material for the production of high alumina (aluminum content ≥48%, belongs to LAS) refractory.

- Q: Which are roofing fireproofing material?

- (1) Foamed concrete is a kind of fire-proof thermal inuslation matertial featured by good fire resistance and thermal insulation. Besides, it is also characterized by excellent sound proofing, penetration resistance, easy construction, safety and environmental protection without toxin and pollution. (2) Foam glass is featured by light weight, small heat conductivity coefficient and water absorbption, non-inflammability, fire resistance, high strength, no moulding, corrosion resistance, non-toxin and stable physical and chemical properties and thus widely used petroleum, chemical engineering and underground construction. It is also featured by thermal insualtion, heat/cold preservation and sound absorbption and thus can be used for thermal insulation of external wall and roof of civil builduing. Foam glass is featured by stable chemical property, easy to be processed and not easy to deforme, and durable. (3) With slag, basalt and other natural ore as the main raw material, rock wool, mineral wool and its products are made by high temperature melting into fiber, and then processing with binder. It has low thermal conductivity, fire resistance, easy construction and good effects of energy saving and thus is highly cost-effective. (4) With phenolic foam material as main material, phenolic resin plate is made by foaming thermoset phenolic resin. It is featured by light weight, fire resistance, no burning in the air, no smoking, non-toxin, no dropping and non-embrittlement and thus is an ideal thermal insulation material used in HAVC projects. Due to its high obturator formamen rate, low heat conductivity coefficient, good thermal insulation, water resistance and water vapor permeability, phenolic foam is an ideal thermal insulation material.

- Q: What types does refractory floor include?

- The categories of refractory are: 1. the best overall performance stone flooring (waterproof, fire retardant) The full name is microcrystalline stone flooring. It is a high-performance waterproof and fire-retardant environmental wood floor synthesized with high and new technology. Its unique raw material is ground calcium carbonate micro-crystalline polymer stone with natural resin and other twenty more imported spreadings. It is formed by refining with high temperature (300 degree centigrade) and high pressure (9,000kg). It is an environmental healthing high-performance material. Its product is innocuous and unpoisonous, and won't age, deform, fade while it is fire retardant, waterproof, maintenance-free and quality, so it is an inevitable repalcement with traditional wood floor. This product has been confirmed as national key promotion program. 2. Wear-resistant composite solid wood floor It is also known as super wear-resistant multi-layer solid wood floor. First stiffening layer surface (based on inorganic materials and steel fibers for paper impregnated with thermosetting amino resin with solid wood or plywood blockboard substrate surface as a combination of facing layer), the front is wear-resistant layer, and the back is balance layer. Thtough hot pressing, it is a grooved and tongued floor, a new impregnated paper laminate floor. It also has the same wear-resistant quality as laminate floor, beauty and foot feel as solid wood floor, stable structure as solid wood composite floor, etc. 3. Waterproof plastic wood floor Plastic wood (also known as "wood plastic" or "plastic wood") composites, and the English name is WOOD-PLASTIC-COMPOSITES, WPC for short.

- Q: On the problem of making refractory materials

- I think D is more appropriate, really want to choose ad can also.

- Q: Who knows about the types of Dalian thermal insulating and refractory materials?

- There are mainly following types: rock wool series, rubber and plastic series, glass wool series, mesh series, ventilation series, mortar series, extruded sheet series, geothermal series, insulation supporting pin series, glass silk cloth series. I hope my answer can help you.

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Sintered Tabular alumina

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Metric Ton/Metric Tons m.t.

- Supply Capability:

- 2000 Metric Ton/Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords