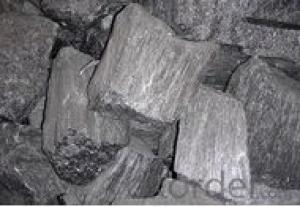

Raw Materials for Refractory - Fused Mullite 70

- Loading Port:

- Tianjin Port or as Customers' Required

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Ton/Tons m.t.

- Supply Capability:

- 10000 Ton/Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Fused Mullite 70:

Place of Origin:China mainland

Material:Alumina Block

Al2O3 Content(%):70-77%

Shape:Block

Specifications of Fused Mullite 70:

| Chemical/Physical Analysis | WFM70 |

| Al2O3 (%) | 60-70 |

| SiO2 (%) | 25-35 |

| Fe2O3(%)Max | 0.8 |

| TiO2(%)Max | 0.2 |

| Na2O+K2O(%)Max | 0.5 |

| Apparent porosity(%)Max | 5 |

| Bulk density(g/cm3)Min | 2.95 |

| Refractoriness(℃)Min | 1750 |

Packaging & Delivery:

Packaging details:1mt big bag or according to customers’ requirements

Delivery:7-15 work days after the order is confirmed

Fused Mullite Applications:

1.Fused Mullite is widely used as raw materials for high grade refractories ,such as the lining bricks in glass kiln furnace and bricks used in hot wind furnace in steel industry .

2.Fused Mullite's also used in Ceramic kiln and petrochemisty industry and many other applications.

- Q: What are the applications of refractory busway?

- Refractory busway is designed for the power supply in fire-fighting equipment, and it can not be used for other purposes. As the generatrix has good heat resistance, thermal insulation, and the heat of the busway can not be emitted, it can not be used long-term at full capacity. In addition to fire-resistant busway, other bus lines can be operated long-term at full load.

- Q: Where is the distributing center of refractory materials in China?

- The construction of Gongyi Chinese refractory chemical industry professional market is a street in Yongan to implement the spirit of the six plenary session of the four session of the Gongyi municipal Party committee, the adjustment of economic structure, an important step in developing the service industry out of the. First, to promote the rapid development of the third industry. Through the improvement of refractory trade logistics system, make Yongan do truly become the first-class refractories trade and logistics center, driven by the refractory industry from the production area to the exhibition, logistics field extension and transformation, become refractory chemical industry center, Yongan office to promote the optimizing and upgrading of economy. Two is to promote intensive land development. Through the integration of resources, the unified planning of the reserved land, intensive development according to the standard of the city, the introduction of powerful investors, construction of large-scale projects. Three is to further create a business atmosphere in Yongan. Refractory chemical professional market operation, will promote the overall development of Yongan to do business, increase the flow of people, logistics, information flow, capital flow, more to promote the rapid development of the third industry in Yongan office.Gongyi Chinese refractory chemical industry professional market completion, will further promote the development of Yongan street service industry, accelerate the pace of economic restructuring, will run the streets of industrial upgrading has played a great role in promoting. Yongan road street is unprecedented high spirited gesture, innovation and development opportunities, so that industrial upgrading and optimization of the pattern to accelerate the realization of, we are convinced that Yongan's tomorrow will be better!

- Q: What are the refractory materials above 1000℃

- corundum would be fine

- Q: Who knows the classifications of magnesia refractory?

- Magnesia chrome series products: The main ingredients of magnesium chromium series are MgO and Cr2O3. Periclase is the first phase and magnesia-chrome spinel is the second phase. Products belonging to this series are magnesium chrome brick and chrome magnesia brick. The main ingredients of magnesium aluminum series are MgO and Al203. As they generate MgO and Al203, all magnesium chromium series products contain magnesia material. magnesium calcium series products The main components are MgO and CaO. They have high melting points, which are important magnesia materials. 5, magnesium silicon series products: The main component of magnesite series is SiO2, when the C / S<5, SiO2 and MgO generate MgO.Al2O3 (forsterite). From the perspective of microscopic mineral, main products of pure aluminum series include magnesium aluminum brick, periclase spinel brick, corundum spinel brick and aluminum-spinel castable in unshaped materials. I hope this answer can help you.

- Q: What's the heat conductivity coefficient of fire-resistant material?

- 5~5 (Unit: W·m-1·K-1). The symbols are λ or K. Thermal conductivity and material properties Thermal insulation material generally is 0, and is related to organizational structure and working temperature. Thermal conductivity of the material refers to the heat transferred from from one plane to another plane in 1 seconds. Generally the thermal conductivity of fire-resistant material is 1. The larger the value is, the stronger the thermal conduction performance is. If the temperature of two planses differes for 1K, then the thermal conductivity is 03~1. The plane cover 1square meter.

- Q: What are fire?ratings of wall thermal insulation material?

- External wall thermal insulation materials are divided into A and B according to combustion level. Grade A is incombustible?material, while grade B is combustible?material. A few years ago, fires in CCTV building and Shenyang hotel resulted from grade B material. Currently grade A is usually used, and some are even cheaper than the grade B material. Grade A is roughly divided into insulation mortar, phenolic board, rock wool board, foam cement board, etc. Insulation mortar is quite good. It is easy and convenient to construct, has low cost, but the production is too simple and it is easy to fake. It is recommend to find a large manufacturer with complete formalities, such as provincal records of production, provincal records of use, city records, type test report at or above the provincial level, national fireproof report and design drawing collection of department of construction. Lack of any is unsafe. It is recommended to use mortar from Hebei Qizheng Haocheng New Building Material Co., Ltd. It is absolutely large manufacturer. MPC thermal?mortar produced by it is recommend product of Department of Construction in Hebei Province! Generally speaking, the combustion of phenolic aldehyde is grade B, but it can barely reach A2 when a thin layer of mortar is wiped outside.

- Q: What kind of refractory decorative board has good quality?

- The unique design and personalized style of well-known brand "transit" rank highest in the field of domestic refractory slab. It is one of the largest manufacturers of high pressure decorating refractory slab in China. The production base covers an area of 40,000 square meters and the annual output is 4 million. It passes the test of Quality Supervision and Inspection Center of National Fire Protection Building Material and ISO9002 certification. The products pass international standards such as 4586, the United States NEMA and so on.

- Q: Who knows the fire endurance of B-level fireproof doors and windows?

- B-grade fireproof windows refer to those fireproof windows whose fire retardant limit is not less than 1 hour. Technical requirements: I. Materials and Accessories (1) Window frame should have a certain strength to ensure the integrity and stability of the steel frame or the wood frame. (2) Steel frame and mound layer can employ galvanized?steel?sheet or stainless steel plate. Its selection criteria should be in line with the stipulation of the Article 5.1 of GB12955 "General Technical Requirements of Steel Fireproof Doors". (3) The selection standard of wood frame and mound layer should be in line with the provision of Article 5.1.1 of GB14101 "General Technical Requirements of Wooden Fireproof Doors". (4) Filling materials inside steel frame and wood frame should be non-combustible materials.

- Q: Pals who know something about fire resistant material please tell me how many types of refractory material there are

- Refractory materials used in special applications include high temperature oxcide, such as alumina, lanthanum oxide, beryllium oxide, calcium oxide, zirconia and other, refractory compounds, such as carbides, nitrides, borides, silicides and sulfides; high temperature composite materials, mainly contain metal ceramic, high temperature inorganic coatings and fiber reinforced ceramics.

- Q: About the use of horseshoe glass kiln refractories

- the lower portion of advanced clay brick, the lower portion of magnesia-chrome brick arch - high-purity silica brick; flue - clay brick; breast wall--33 # fused zirconia corundum brick (with shrinkage); fused zirconia bottom --33 # fused zirconia corundum brick (with shrinkage); regenerative chamber- the upper part of sintered magnesia-chrome brick, cooling section 33 # electric?smelting no shrinkage fused zirconia corundum brick; the wall - the melting section 41 # no shrinkage fused zirconia corundum brick (including 41% of zirconium; the lattice- superstructure of high purity magnesia brick, the same below); small stove --33 # fused zirconia corundum brick (with shrinkage). It can be said that it is the maximum configuration, if the funds is limited it can be downshift appropriately.

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Raw Materials for Refractory - Fused Mullite 70

- Loading Port:

- Tianjin Port or as Customers' Required

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Ton/Tons m.t.

- Supply Capability:

- 10000 Ton/Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords