Strataweb Geocells Biaxial Uniaxial Triaxial Plastic Geogrid with Bitumen Coated Black - China Made

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

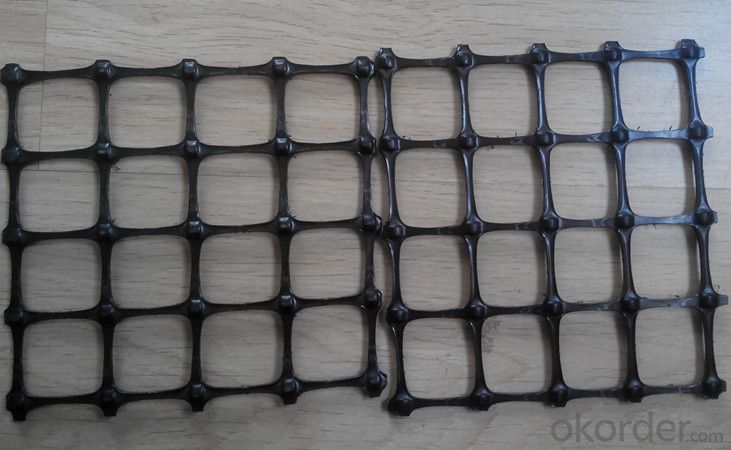

Groupeve Plastic Geogrid is made of high molecular polymer through extrusion, forming and punching before longitudinal and lateral stretching, including HDPE Geogrid, PP Geogrid. This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

Features

Increase the bearing capacity of the roadbed and foundation and prolong their service life.

Prevent road surface and foundation from sinking or flawing, keep clean and beautiful ground surface.

Convenient construction saves time and labor, reduce mounting time and decrease maintenance expense.

Prevent culverts from flawing.

Enhance earth slope and prevent water loss and soil erosion.

Decrease under layer thickness and save manufacturing cost.

Enhance the stability of side slope turf net patch to improve greening.

Replace wire netting used in mine as intermediate ceiling netting.

It is of fire-retardant and anti-static

Applications

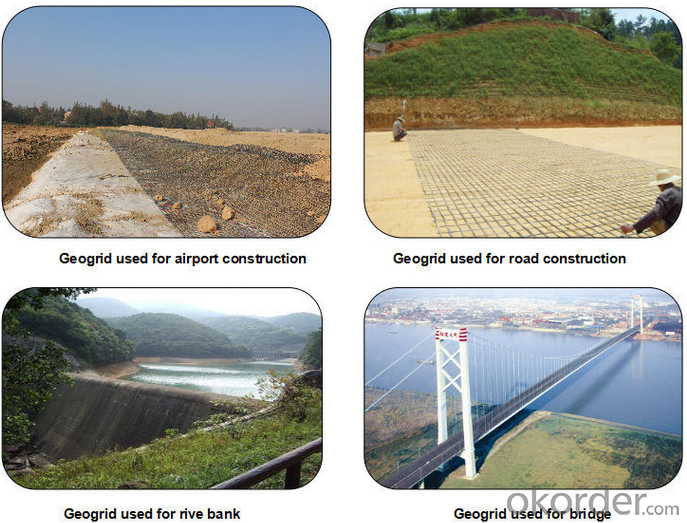

Plastic geogrids can be used to enhancement of permanent bearable toft including roads and railways embankment, slopes, tunnel, airfields, parks, docks, and ground which cargo lays on and their main usage are as follows:

1. Enhance the bearing capacity of road foundation and extend the duration of roads

2. Prevent road surface from collapse, crack and being dirty

3. Be convenient for construction, time saving and cut down the cost of maintenance

4. Prevent tunnel from crack occurring

5. Further solidity slopes to proof water and soil from losses

6. Reduce the surface thickness of the ground

7. Consolidate the net for growing grass on the slopes so as to stabilization surrounding virescence

8. Be used for artificial top net of mines instead of metal ones.

Packaging & Delivery

| Packaging Details: | Rolls |

| Delivery Detail: | 20 Days |

Detiled Data

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

F&Q

1 How about the delivery time? Lead time since receipt of 30% T/T deposit payment: 3 weeks.2 What kind of payments does jenor support? T/T 3

What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4

How to deal with the sample charge?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

And we will return the freight fee If you set the order .

5

Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6

Can you tell me your main customers?

That's our customers' privacy, we should protect their information.

At the same time, please rest assured that your information is also safe here.

- Q: Can geogrids be used in landfill applications?

- Yes, geogrids can be used in landfill applications. Geogrids are commonly used in landfill construction to improve the stability and performance of the landfill liner system. They help in reducing the potential for soil erosion, enhancing the load-bearing capacity, and providing reinforcement to the liner system.

- Q: Are geogrids resistant to chemicals and environmental degradation?

- Yes, geogrids are typically designed to be resistant to chemicals and environmental degradation. They are made from materials such as high-density polyethylene (HDPE) or polyester, which have excellent resistance to chemical attack and can withstand harsh environmental conditions, including exposure to UV radiation and temperature variations. These properties make geogrids durable and reliable for various engineering applications.

- Q: How are geogrids used in civil engineering?

- Geogrids are used in civil engineering to reinforce and stabilize soil structures. They are typically made of high-strength polymer materials and are placed within the soil to provide additional strength and stability. Geogrids help distribute loads, prevent soil erosion, and improve the overall performance of infrastructure projects like roads, retaining walls, and embankments.

- Q: The effect of steel and plastic grille in steel and plastic grille

- purposeApplicable to all kinds of plastic grille dam and embankment reinforcement, slope protection, wall reinforcement, large airport, parking lot, freight yard and permanent foundation reinforcement.

- Q: What is the 110 type bidirectional geogrid?

- As the polymer in the manufacture of plastic polymer in the process of heating with the extension of the process of re orientation, strengthen the link between the molecular chain force, to achieve the purpose of improving its strength. Its elongation rate is only 10% ~ ~ of the original plate of 15%. If the carbon black and other anti-aging materials are added in the geogrid, the utility model has the advantages of good acid resistance, alkali resistance, corrosion resistance, aging resistance and the like

- Q: Are geogrids suitable for use in mine tailings containment?

- Yes, geogrids are suitable for use in mine tailings containment. Geogrids are commonly used in various civil engineering applications, including mine tailings containment, due to their high tensile strength, durability, and ability to reinforce soil. They can effectively stabilize and reinforce the tailings, preventing slope failures and controlling erosion. Additionally, geogrids can enhance the overall stability and longevity of the containment system, making them a reliable choice for mine tailings management.

- Q: How do geogrids help in preventing differential settlement?

- Geogrids help in preventing differential settlement by providing structural reinforcement and stability to the soil. They distribute and transfer loads more evenly, reducing differential settlement by limiting soil movement and maintaining a more uniform foundation support.

- Q: Can geogrids be used in reinforcement of underground parking structures?

- Yes, geogrids can be used in the reinforcement of underground parking structures. Geogrids are commonly used in civil engineering projects to improve soil stability and provide structural support. In underground parking structures, geogrids can be installed to reinforce the soil, distribute loads, and reduce the potential for soil settlement and structural failure. This helps to enhance the overall stability and longevity of the parking structure.

- Q: What are the factors affecting the durability of geogrids?

- The factors affecting the durability of geogrids include the material composition of the geogrid, the quality of the manufacturing process, exposure to UV radiation, chemical exposure, temperature fluctuations, installation techniques, and the level of stress or load placed on the geogrid.

- Q: Do geogrids provide reinforcement to geosynthetic liners?

- Yes, geogrids can provide reinforcement to geosynthetic liners. Geogrids are typically used in geosynthetic liner systems to enhance the overall strength, stability, and performance of the liners. They help distribute loads, reduce deformation, and improve the long-term performance of geosynthetic liners.

Send your message to us

Strataweb Geocells Biaxial Uniaxial Triaxial Plastic Geogrid with Bitumen Coated Black - China Made

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords