Ultra-White Glass/Super Clear Glass Cheaper Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass:

We manufacture a wide range of glass to meet your different demands: Float glass, Tinted glass, Stained glass, Laminated glass, Mirror glass, Aluminum mirror, Silver mirror, Reflective glass, Online coated glass, Patterned glass, Figured glass, Wired glass, Colored glass, Tempered glass, Toughened glass, Safety glass, Shower doors glass, Emulsificated glass, Acid-etched glass, Obscure glass, Sandblasted glass, Solar glass, Ultra clear low iron glass, Low-E glass, Obscure glass, Glass block, Glass brick, Picture frame in different colors and sizes.

2.Main features of Glass:

1) Standard: CCC, intertek

2) 3 - 19mm float glass

3).Size: customized sizes available

4).tempered or silk

5).drill work available

6).Printing Furniture Glass ,Beautiful surface with good coverage.

Profiled glass, as your design and requirement

Type: clear, tinted, color glazed, coated, Low-E, IGU and laminated glass etc.

3.Glass Images:

4. Glass Technical Parameters:

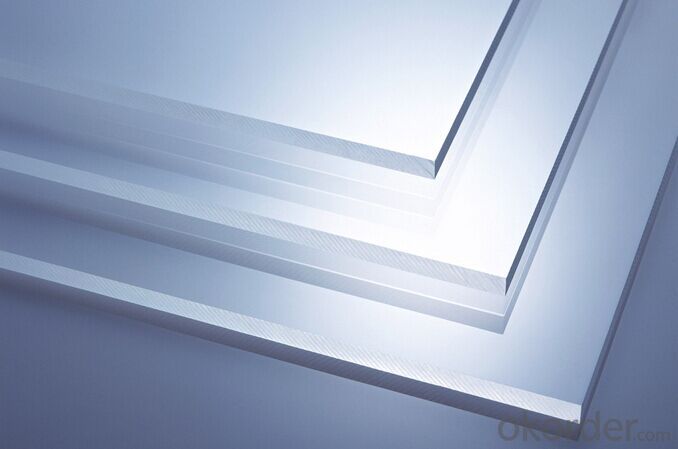

CLEAR FLOAT GLASS

Thickness: 2mm-19mm

Sizes: 1524x2134mm, 1830x2440mm, 2140x3300mm, 2140x3660mm, 2250x3300mm, 3660x2140mm, 3660x2250mm etc.

EXTRA CLEAR GLASS

Thickness: 3mm-19mm

Sizes: 1830x2440mm, 2140x3300mm, 2140x3660, 2250x3300mm, 2250x3660mm etc.

TINTED GLASS

Colors: Euro Bronze, Golden Bronze, Euro Grey, Mist Grey, Dark Grey, French Green, Dark Green, Lake Blue, Dark Blue, Ocean Blue, Pink etc.

Thickness: 3mm-12mm

Sizes: 1524x2134mm, 2140x3300mm, 2250x3210, 2250x3300mm, 2140x3660mm, 2250x3160mm etc.

REFLECTIVE GLASS

Colors: Euro Bronze, Golden Bronze, Euro Grey, Dark Grey, French Green, Dark Green, Lake Blue, Dark Blue, Pink, Silver etc.

Thickness: 3mm-10mm

Sizes: 1524x2134mm, 2140x3300mm, 2250x3210, 2250x3300mm etc.

MIRROR

Types: Silver Mirror, Aluminum Mirror, Copper and Lead Free Mirror, Safety Mirror, Solar Mirror and Beveled Mirror etc.

Thickness: 1.5mm, 1.8mm, 2mm, 2.7mm, 3mm, 4mm, 5mm and 6mm etc.

Sizes: 1524x2134mm, 1830x1220mm, 1830x2440mm, 2140x3300mm, 2250x3300 etc.

LAMINATED GLASS

PVB Color: Clear, Green, Blue, Bronze, Grey, Milk white etc.

Glass Color: Clear, French Green, Dark Green, Ford Blue, Dark Blue, Bronze, Euro Grey etc. Float glass and reflective glass are available.

Thickness: 3+0.38+3mm, 4+0.38+4mm, 5+0.38+5mm, 6+0.38+6mm, 3+0.76+3mm, 4+0.76+4mm, 5+0.76+5mm, 6+0.76+6mm etc. till to 42.3mm

Sizes: 1830x2440mm, 2140x3300mm etc.

PATTERNED GLASS

Thickness: 3mm, 3.5mm, 4mm, 5mm, 6mm and 8mm

Sizes: 1220x1830mm, 1524x2134mm, 1830x2440mm, 3300x2140mm etc.

Patterns: Aqualite, Bamboo, Beehive, Chinchilla, Crystal, Diamond, Flora, Karatachi, Masterlite, Millennium, Mistlite, Morgon II, Moru, Nashiji, Rain and Wanji etc.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How is the glass made?

- When the art glass molding process and mold blowing into the two, and, this is blowing method, the raw materials, and fused to Microsoft without flowing, stick in the end pipe, the other end like blowing balloon blowing, the hollow expansion, while the soft, plastic processing,,, burning soft glass a little stiff, you have to reach in the heating furnace,

- Q: Is acrylic organic glass?Which is more expensive, acrylic or plexiglass?

- Acrylic is English Acrylics, Acrylics is acrylic acid (ester) and methacrylic acid (ester) general class of chemicals. People often say that the acrylic sheet is polymethyl methacrylate (PMMA) plate, which is composed of methyl methacrylate monomer (MMA) polymerization.

- Q: Cement / glass raw materials, equipment, principle, composition, characteristics, uses and types

- Ceramic composition used in high melting ceramics is used by manufacturers and is hardly used to make individual ceramic restorations. The material contains 75% to 85% feldspar, 12% to 22% quartz and 4% kaolin. Feldspar forms glass phases, and quartz remains suspended in the form of quartz after sintering. Quartz (SiO2) is used as an intensifier in ceramics. At normal sintering temperature, it has no structural change and plays a role in stabilizing the bulk (mass) at high temperatures.

- Q: Who has information about power plants chimneys, water glass, acid resistant concrete?

- The characteristics of water glass concrete acid: water glass acid resistant concrete with water glass as binder, sodium fluorosilicate as hardening agent, adding acid powder and acid aggregate or other additives according to a certain proportion. Features: the acid and good heat resistance, it can resist all kinds of strong oxidizing acid (such as sulfuric acid, hydrochloric acid, nitric acid) and most corrosive gases (oxygen, sulfur dioxide) erosion at high temperature (1000 DEG C) still has good acid resistance, mechanical strength and high. But this material is not resistant to hydrofluoric acid, more than 300 degrees of hot phosphoric acid and higher fatty acids or oleic acid erosion. Is a commonly used anti-corrosion material, it has a wide range of materials, acid resistance good, low cost advantages. Its disadvantages are no alkali resistance, poor impermeability and water resistance, complex construction, long maintenance period.

- Q: Yacht enterprises are purchasing their own raw materials (resin, glass fiber, carbon fiber, etc.), home composite products, accessories?

- I do PVC mesh fabric, and it should be used on the hull of your yacht

- Q: What are the raw materials of water glass?

- The water soluble alkali metal silicate glass is formed by the combination of alkali metal oxide and silica, also called paohuajian. Water glass can be divided according to the type of alkali metal sodium silicate and potassium silicate, the molecular formula of N and K2O.nSiOz. in Na2O.nSiO2 coefficient is called the modulus of water glass, molecular oxidation silicon and alkali metal oxides in water glass ratio (or molar ratio). The modulus of water glass is an important parameter of water glass, generally between 1.5-3.5. The greater the modulus of water glass, solid water glass is difficult to dissolve in water, which can dissolve in water at room temperature for n 1, n is required to increase the water solubility. N is greater than 3 to 4 above atmospheric pressure steam can be dissolved. The modulus of water glass is larger, more silicon oxide content, water glass viscosity, easy decomposition hardening, bond strength increases.

- Q: How is glass made, raw material proportioning?

- The glass is the main component in the manufacturing process of quartz sand, quartz sand is combined with other chemical materials at high temperature (1300 degrees Celsius) crystallized after firing the cooling of the body, with a hard, abrasion resistance, corrosion resistance and high transmittance characteristics, its wide application has a long history.

- Q: Why are most of the chemical instruments made from glass?

- Because experiments require high temperatures, heating, freezing, and many complex processes of chemical reactions,

- Q: Is flat glass the main material or structural component in raw materials?

- The general case is the principal. Such as doors and windows, glass, glass partition, ceiling, and so on.

- Q: What are the construction principles and raw materials of tempered glass?

- Any of the above factors are closely related to the heating and cooling conditions of glass. When the glass is uniformly heated to the tempering temperature, it suddenly cools down. Because of the different cooling rate of the inner and outer layers, the surface layer cools and contracts rapidly, while the inner layer cools and contracts slowly. As a result, the inner layer is subjected to compressive compressive stress and the surface layer is subjected to tensile stress. As the glass continues to cool, the surface has hardened and stopped shrinking, while the inner layer is still cooled and contracted until the room temperature is reached. In this way, the surface layer is compressed by the compression of the inner layer, and the inner layer forms tensile stress and is permanently retained in the tempered glass. Because the glass is strong and weak tensile compressive brittle material, when the glass is broken more than tensile strength, so the size and distribution form of stress is the main factor influencing the strength of glass and crack. In another case, when the glass is cooled in a plastic state, whether it is uneven heating or uneven cooling, as long as there is a temperature difference on the same piece of glass, there will be different shrinkage. At room temperature, the higher the temperature, the greater the cooling, and the greater the shrinkage, the shorter the glass. On the contrary, the lower the temperature is, the less the cooling, the smaller the shrinkage, and the longer the glass. If a piece of glass is short of each piece, the board must be warped. In this way, it is not difficult to understand why glass is deformed and how to prevent deformation.

Send your message to us

Ultra-White Glass/Super Clear Glass Cheaper Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords