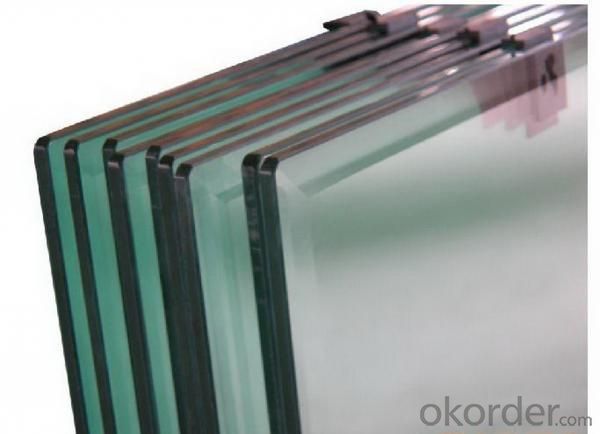

Clear Tempered Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tempered Glass is a kind of safety glass with perfect quality.

Features of Clear Tempered Glass:

1、It can maintain the original flatness and transmittance of float glass with no wave and buckling after tempered.

2、Stress Marks on a single piece or multiple pieces of tempered glass cannot be seen with naked eyes under any natural light.

3、The distortion caused by airflow marks and white fogs is removed, which is difficult for common tempered glass.

4、Furthermore, good transmittance is maintained.

Specifications of Clear Tempered Glass:

Thickness: 5-25mm

Size:

Max Size: 2440*8000mm

Min Size: 300*300mm

customized size

Applications of Clear Tempered Glass:

It is mainly used in curtain walls, shower rooms, furniture, guardrails, pool fences, etc.

- Q: What are the main raw materials for making ceramics, glass and cement?

- The main raw materials for glass production are quartz, feldspar (potassium feldspar, albite) and soda ash

- Q: What are the aluminum films used in glass processing enterprises?

- (1) the enterprise purchase and acceptance of storage materials, the planned cost or actual cost, debit "raw material" subjects, according to the actual cost of credit "material procurement" or "goods in transit" subjects, according to the difference between the planned cost and actual cost, debit or credit "material cost difference" course.

- Q: How to distinguish between good and bad glass fiber reinforced plastic?

- Glass steel will be exposed his true strength in the actual use of the process, the quality of glass steel after a few years of use color slightly dim, the whole board intact, no obvious damage, glass steel it would withstand the test of practice, after a few years of use will appear corrosion fracture pores and other obvious damage the board is not so smooth, the color degradation is serious, the overall aging, general glass steel is to be used for twenty years, but two years later will appear glass steel inferior overall aging phenomenon, thus causing great losses to customers.

- Q: What is the raw material of glass fiber reinforced plastics and what is the matching ratio?

- The main raw material is unsaturated resin and fiber cloth,

- Q: Does the material of sunglasses choose good glass or plastic?

- Glass materials of high hardness, not prone to scratches, shock resistance is poor, after the impact of easily broken, and the weight is relatively heavy.

- Q: The younger brother wants to know how the octagonal bead is produced Do you use one side of the machine to grind it? What kind of material is usually used in China? Is the price fixed according to the material used?

- C grade crystal beads: batch of beads and emery particles mixed, polished together in the polishing machine, and then mixed with polishing powder, batch polishing, and thus again!

- Q: What is the raw material of glass?.

- 1. the main raw material of glass(1): the main component of silica sand or borax borax glass is introduced into silica or silica or boron oxide, which alone can melt into a glass body in the combustion, determines the main properties of glass, appropriately called silicate glass or borosilicate glass.(2): the main ingredients of soda soda or salt and mirabilite into glass is sodium, they can with silica sand and other acidic oxides formed in the fusible salt calcination, the fluxing action, the glass is easy to mold. But if the content is too much, the thermal expansion rate of glass will increase, and the tensile strength will decrease.(3) limestone, dolomite, feldspar, etc.: the main component of limestone introduced into glass is calcium oxide, which enhances the chemical stability and mechanical strength of glass. But the content is too much, which makes the glass break and reduce the heat resistance.As a raw material for introduction of Magnesium Oxide, dolomite can improve the transparency of glass, reduce thermal expansion and improve water resistance.Feldspar, as a raw material for introduction of alumina, can control the melting temperature and increase durability. In addition, potassium feldspar can also provide components, improve the thermal properties of glass.(4) broken glass: Generally speaking, not all new materials are used in the manufacture of glass, but the broken glass of 15%--30%.

- Q: What are the construction principles and raw materials of tempered glass?

- Tempered glass is the two processing product of flat glass. The processing of toughened glass can be divided into physical toughening method and chemical toughening method. Physical toughened glass is also called tempered tempered glass. It is the ordinary flat glass in heating furnace heated to the softening temperature close to the glass (600 DEG C), the internal stress of the self deformation is eliminated, and then removed from the glass furnace, with long nozzle high pressure cold air blowing glass on both sides, the rapid and uniform cooling to room temperature, well tempered glass can be made. This kind of glass in the internal and external tension compression stress state, once the local damage occurs, the stress release, the glass is broken into small pieces, these small pieces no sharp edges, not easy to hurt. In the production of tempered glass, the most influential factor on the quality of the product is how to make the glass form a larger and uniform internal stress. But the greatest impact on yield is how to prevent cracking and deformation.

- Q: Failure reasons and solutions of insulating glass.

- The production of hollow glass raw material quality; key factors affect the service life of hollow glass sealant is ageing resistance and desiccant adsorption capacity, and the determining factor is the performance of sealant. Because no matter how much the desiccant adsorption capacity, inside the hollow glass after a certain limit, when the hollow glass desiccant completely saturated, again good desiccant also unable to water vapor adsorption, then the hollow glass is invalid. Only when the sealant has good sealing performance, moisture permeability coefficient is low, the amount of water vapor into the hollow glass rarely, and keep this state, only rarely can guarantee the hollow glass desiccant inside gas drying, so as to ensure the effect of hollow glass.

- Q: What materials are needed for the production of glass bottles and what are their proportions?

- There are many kinds of glass, different kinds, different uses, and different ingredients.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2007 |

| Annual Output Value | US$ 0.3-0.5 Million |

| Main Markets | East Europe; Southeast Asia; Africa; Mid-East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 10000.00 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Clear Tempered Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords