Safety Ultra Clear Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

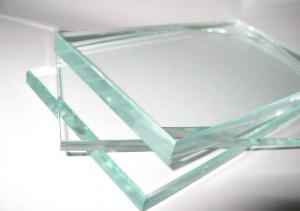

Ultra Clear Glass is a kind of low iron and transparent glass with high light transmittance(>91%), also called low iron glass. It is a high-quality, multifunctional and newly high-end glass. Being crystal clear and elegant, it is crowned as "crystal prince" of the glass family.

Features:

1. High clarity: 6% higher visible light transmittace than ordinary clear glass;

2. Nobility and elegance:with the unique lavender edges , it has the feeling of the the sapphire against the sunshine.

3. Safety: No detonating impurities/metallic and no spontaneous detonation.

4. Low UV transmittance and Environmentally friendly products: can effectively prevent UV radiation and protect interior items from fading and aging.

5. CE/SGS/REACH Certificates.

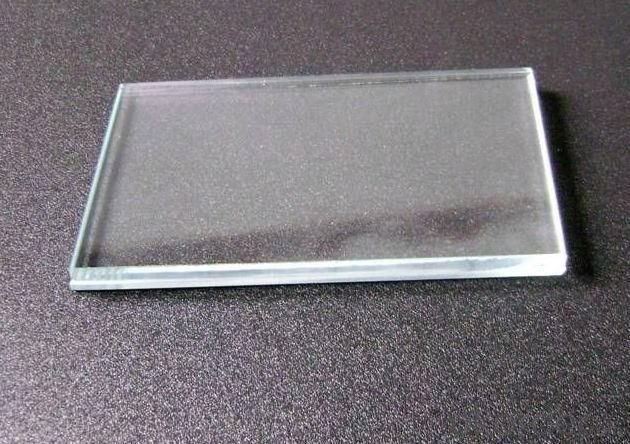

Specifications:

Thickness: 2- 25mm

Size:

920*1016mm

3660*18000mm

Customized Sizes

Applications:

Ultra Clear Glass has been widely used in various fields:

1. Interior and Exterior Decorations of Advanced Buildings: like curtain walls, glass doors of the lobby, transparent roof, glass ribs, glass suspended ceilings, partitions, walls, guard rails, stairs, etc.

2. Exhibition Hall and Showcase: in museum, exhibition hall, jewelry shop, clothing store, etc.

- Q: How do you make the glass, please? What is the raw material?

- You can melt the sand and then try to remove the magazine and turn it into glass.

- Q: What is the raw material of glass made of?

- Our daily contact with most of the "flat glass is" thick to thin for doors and windows, clocks and the use of medical tests, the manufacturing method is that the furnace in the glass slurry level or traction method (also called float) and vertical traction method. After the dissolution of soluble traction after furnace also has the cooling system, cooling after the completion into a "flat glass, flat glass thickness mainly depends on the speed of traction, traction faster, can be manufactured and thinner. Although the ordinary flat glass from the front appears bright transparent, but from the side near the edge is slightly blue, because the amount of glass color depends on the main raw material in the manufacture of glass - quartz sand and iron content of purity. Generally, the thin glass used in the watch industry is superior in quality but expensive in value. The main difference is that the raw material used in the quartz sand is superior and the iron content is very low (usually under 3/10000)

- Q: What is glass made of?

- The glass has undergone intense temperature changes and shape changes during forming, leaving a thermal stress in the glass. This thermal stress will reduce the strength and thermal stability of glass products. If it is cooled directly, it is likely to rupture in the course of cooling, during or after storage, transportation, and use (commonly known as cold blasting of glass). In order to eliminate the cold explosion phenomenon, glass products must be annealed after forming. Annealing is to preserve or slow down a temperature for a period of time in order to eliminate or reduce the thermal stress in the glass to the allowable value.

- Q: Is it a vacuum cup with fluorine coating that affects the health?

- The elemental substance of fluorine is F2, which is a pale yellow [1], highly poisonous gas. Fluorine gas corrosion is very strong, very active chemical properties, is one of the most oxidizing substances, and even some inert gases can react under certain conditions [2]. Fluoride is a special plastic, rubber and freezers (freon-12) key elements in. Because of the special chemical properties of fluorine, fluorine chemistry plays an important role in the development of chemistry.

- Q: What are the anticorrosive materials for glass fiber reinforced plastic?

- Finished product protection: because the construction environment belongs to the pool irrigation, it is not conducive to the curing of epoxy forming, so it must take 48 hours curing time, to be fully cured after use.

- Q: Why is toughened glass broken?

- There are a variety of predisposing factors. Tempered glass explodeFor example, A. before the installation of glass is accidentally damaged, like chipping, knocked the feet, because the glass is tempered around the weak area, its strength even weaker than the non tempered glass, but this part of the damage are not likely to cause the glass immediately burst, but changed the internal stress of glass. When the upper wall is used, the internal stress changes gradually, which breaks the glass.B. such as differences in temperature after installation. As you say, temperature, weather, and so on, will make the internal pressure of the glass partial uneven, thus causing burst.Is there a correct size for the C. installation?. If the installation is too tight, the specifications are not appropriate, it will cause stress changes inside the glass, causing a burst.D. the rest is external force, including impact, extrusion and so on. It's not just human impact, or other things, or even wind in nature. If the glass does not fall on the ground, there will be the point of impact (if it is obvious, there will be explosive, Hu Dieban) these can be invoked, but if in the proceedings can only be said to be a possibility, because you have no evidence to prove that. In the domestic situation, the glass manufacturers generally compensate for the glass trouble.

- Q: What material can not be sprayed on the glass?

- If you want to spray characters on the glass, it is impossible to follow the glass unless it is frosted. If you really want to spray words on the glass, you can go directly to the print shop, do the word, and then stick it up.

- Q: The difference between glass wool, rock wool, mineral wool

- Mineral woolCotton like short staple fibers made from silicate melts, including slag cotton, rock wool, glass wool and ceramic fibers, generally only refer to the first two.By the above two concepts, we should compare the difference between rock wool and slag cotton.

- Q: What are the materials for car windshields? Is there anything different than ordinary glass?

- At present, the front windshield of the car is mainly made of laminated glass and sandwich area toughened glass, and it can bear strong impact force.

- Q: What raw material is the front bumper of the car made of?

- Toughened glass is a kind of prestressed glass, in order to improve the strength of the glass, the methods commonly used in chemistry or physics, formed on the surface of glass glass under compressive stress, first offset surface stress force, so as to improve the bearing capacity of reinforced glass, its wind, cold, impact etc.. Notice that it is different from fiberglass.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1964 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Safety Ultra Clear Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords