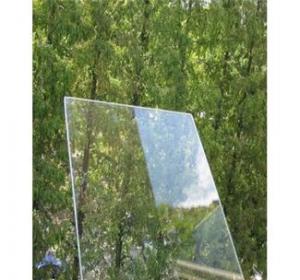

Solar Low-E Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Solar Low-E Glass is a kind of low iron glass with ultra clarity, its normal light transmittance is higher than 91%. With its high performances like stability and good processability, it’s specially used for solar photovoltaic ( PV ) and photo-thermal products.

Features of Solar Low-E Glass:

1. Excellent Optical Performances.

2. Good Processability.

3. Complete Product Series.

4. Continuous and Stable Supply.

5. Excellent Service: Supplying the endusers for utilizing solar energy with “made-to-order” production and “one-stop” procurement service from original glass sheet to further processing (Washing, Grinding, Tempering and Drilling) to comprehensively satisfy customer’s requirements.

6. Technical Parameters:

Transmittance (3.2mm Glass)

Specifications of Solar Low-E Glass:

Thickness: 3mm, 3.2mm, 4mm and 5mm Size: 3660*2440mm3660*2134mm

customized sizes

Applications of Solar Low-E Glass:

Solar Low-E Glass can be used in the following aspects:

1. Superstrate of Thin-film Solar PanelsWith higher solar light transmittance, it can improve the photoelectric conversion efficiency of the solar cells.

2. Flat Solar CollectorsWith higher visible light transmittance, it can improve the photo-thermal conversion efficiency of the solar collectors.

3. Solar MirrorsTake full advantage of extremely high reflectivity of the ultra clear glass mirror to improve the thermal efficiency, thereby to enhance the overall efficiency of thermal power generation.

4. BIPV Project (Building Integrated Photovoltaic)In the BIPV project, Solar Low-E Glass (and TCO glass) can be used for both front-panel glass and seal glass of the thin-film solar cell. In photoelectric curtain walls, Solar Low-E Glass can not only satisfy the requirements of indoor lighting but also help the photovoltaic efficacy of power generation, it will be the main development trend of future buildings.

5. Greenhouse GlassSolar Low-E Glass can accelerate the plants’ photosynthesis and shorten the growth period, help clients gain more economical benefits.

- Q: Which glass factory has good glass?

- If the original piece of glass with good quality of Qingdao Jin Jing, Jiangmen farun, TGI, CSG, luoyang.... These glass plants are relatively stable, and is a large enterprise, if the processing technology is good, it depends on the processing unit of the process, this is not recommended.

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Because I work in the glass curtain wall project, only know raw materials to do a glass curtain wall material impact strength test before installing the unit model, in a special laboratory, no experimental requirements should be in the process of construction, the construction of the end of may do some water resistance experiment. Hope to be of help to you!

- Q: List and characteristics of chimney glass flake cement

- Due to the relative stretching coefficient of the steel, cement and other material and substrate, so in the case of heat shock resin layer easily cracking and shedding, and glass flake could commission a heat stable layer, which can prevent the substrate cracking and spalling.

- Q: Method for cutting thick glass

- Cutting glass with abrasivesThe original A. plus sand saw diameter 95300 ~ 400mm, 1 ~ 2ram thick brass, iron plate made of circular plate, rotated, injection abrasive (silicon carbide, corundum, corundum and so on) and the slurry water mixed, with some of the side of the glass to the saw cutting force.B. with ordinary abrasive cutting compared with ordinary wheel, diamond grinding wheel, it is difficult to cut thin products, cutting losses, grinding wheel wear, wheel but cheap, especially in dry cutting, it is common to the advantages of grinding wheel cutting.C. wire cutting with multiple jointless wire (wire or piano wire = O.05 ~ 0.2mm), can also cut about 100 sheets. The edge of the abrasive material is added to the workpiece with a certain amount of pressure, and the edge is milled and cut. Because of the grinding surface cutting, the margin is very small, you can get high-precision cutting.D. abrasive jet machining method and principle of the same blast form, but the use of abrasive powder (average particle diameter of 27 m, with a tiny belly) jet nozzle (spraying gas as carbon dioxide, nitrogen and compressed air), shot edge pores, edge cut glass plate. The impact of the abrasive is so small that it will not damage the glass. This method can process thin glass plates.

- Q: How is glass made?

- Technological process:1, raw materials broken: the above raw materials broken into powder;2, weighing: according to the list of ingredients, called a certain amount of powder;3, will be called: the mixed powder mixing, stirring into a batch (colored glass and colorant);4, melting: the mixture into the glass furnace, melting at 1700 degrees into glass;5, forming: the glass liquid into a tin bath (float), pull machine (lattice method), rolling machine (rolling method, adding metal wire is wire glass), forming the flat glass;6, annealing: the molding of glass products into the annealing furnace annealing, balance the stress, to prevent self cracking.

- Q: Polypropylene short fiber and glass fiber if different

- Glass fiber and polypropylene fiber are different in proportion, glass fiber will sink in water, and polypropylene fiber is suspended in water;

- Q: What kind of material is made of automobile glass?

- Glass raw material, main raw material, quartz sandThe main raw material of automotive glass is pressure PVB and glass substrate

- Q: What kind of material is the toughened glass film made of mobile phone?

- Tempered glass membrane should be made of tempered glass = =, but this film is not so magical propaganda

- Q: What are the materials for car windshields? Is there anything different than ordinary glass?

- Prospects: glass technology has now completely penetrated the automotive industry, becoming an indispensable part of the automotive technology field. Although China is still the automotive industry such as glass and glass industry (BSG) belong to two different areas of the industry, the former belongs to the machinery manufacturing industry, which belongs to the light industry, but from the development of the car, the relationship between the two is more and more close. Nowadays, people always study and develop automotive glass from the perspective of automobile safety and appearance, and introduce new varieties.

- Q: Use of glass flake cement

- Good temperature resistance. The use of glass scale lining, its heat resistance than similar resin coating can be increased by 20-40 degrees, so often used in oil pipelines, hot water pipelines, heat resistant chemical devices.

1. Manufacturer Overview

| Location | Shenzhen, China |

| Year Established | 1984 |

| Annual Output Value | |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen, China |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Solar Low-E Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords