Natural Graphite Electrode - UHP Grade Graphite Electrode with Nipples for Ladle Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

Topfly Material has complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line.

Graphite electrodes, widely used in steelmaking, non ferrous, silicon industry. According to their level of quality, it can be divided into RP, HP and UHP grade. This item is for UHP grade graphite electrode. Resistivity: ≤5.5ohm, Bulk Density: ≥1.68g/cm3. Diameter is 350-700mm, length is 1800±100mm.

2.Main Features of the Graphite Electrode

(1) High quality and carbon content.

(2) Competitive price, we have price advantage for UHP.

(3) High density ≥1.68g/cm3 and low resistivity≤5.5ohm

(4) Large quantity in stock, you can order directly.

3.Graphite Electrode Images

More products for your reference:

Packaging: Wooden Pallets

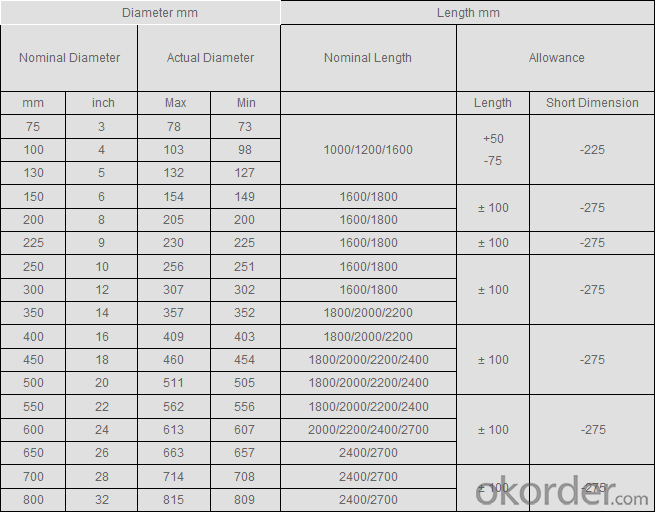

4.Graphite Electrode Specification

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(2) MOQ

For trial order, we accept 5 MT.

(3) Payment term

30% deposit, balance against the BL copy; 100% L/C at sight.

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit or L/C.

- Q: Classification, uses and manufacturers of graphite electrodes

- Classification of graphite electrodes:(1) common power graphite electrode (RP), (2) high power graphite electrode (HP), (3) quasi ultra high power graphite electrode (SHP), (4) ultra high power graphite electrode (UHP) Note: poly carbon classification method

- Q: Why use platinum ferroalloy instead of iron as electrode?

- General industrial grade silicon dioxide, because the preparation technology is different, can be divided into two types, one is dry, sintered (Fume Type), a wet precipitation type (Precipitated Type), and two of the surface area, the surface with hydroxyl (-OH) are the same, in general, the former the latter is more, less, the two surface has the tendency of hydrophilic, as for lipophilic polymer, such as paint, rubber... Etc.,... If the silica surface pre rendered hydrophobic, has a good effect.

- Q: Use of graphite in steelmaking

- Graphite can be used as an agent for carburizing in the steel making industry. Carburizing uses a wide range of carbonaceous materials, including synthetic graphite, petroleum coke, metallurgical coke, and natural graphite. Worldwide, the use of graphite for carburizing is still one of the main uses of earth like graphite.

- Q: Why should the carbon brush for the trolley be made of graphite?

- Graphite has good conductivity

- Q: What is the reason that the current cannot be increased when the graphite electrode is used for anode electrolysis?Add calcium chloride and sodium bicarbonate into electrolytic water

- Because in the process of electrolysis of water in cathode electron generated hydroxyl, the alkaline solution increased. But with the hydroxyl reaction of sodium carbonate and sodium bicarbonate, carbonate and calcium ions exist at the same time, must produce the precipitation of calcium carbonate, the ion in the solution is reduced, thereby conductive resistance increases. Thus weakened over time current cannot be raised

- Q: Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- No, sodium sulfite reacts with the oxygen produced.

- Q: In EDM, the electrodes are made of graphite and copper. Please tell us the difference between them

- Graphite is characterized by coarse particles, fine particles and ultrafine particlesFor different processing, you can choose different particles, the smaller the particle size, the higher the accuracyCopper has good conductivity and thermal conductivity and is used in many occasionsBut there are many factors to consider in the choice between the two

- Q: Please senior doubts. The graphite electrode is used in the mold cavity In what case is graphite processing taken?

- Graphite electrode has better machining stability and high production efficiency. It is easy to be used as EDM electrode material in EDM when it is processed with long pulse width and high current.

- Q: Carbon graphite electrode and what is the difference?

- Graphite electrode is a mixture of natural graphite and petroleum coke and asphalt coke. After being treated by high temperature graphitization, the material is composed of graphite;

- Q: Jiqiu conductive graphite electrode, how to compare with copper is relatively large resistance value?

- This is not a good estimate of the sheet graphite resistance after 5mm

Send your message to us

Natural Graphite Electrode - UHP Grade Graphite Electrode with Nipples for Ladle Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches