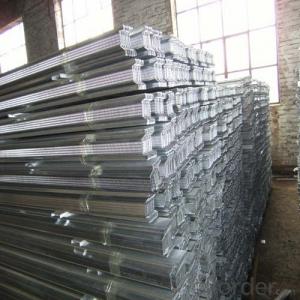

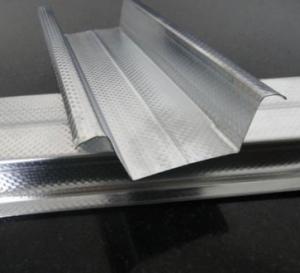

U-Shape Ceiling Profile System

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications and Advantages:

1. Material: Galvanized Steel Sheet

2. Items: Crab connector, U-shape, Wall angles and etc.

3. Size: Standard or customized

4. Use: For steel profile (ceiling and partition systems)

5. Easy and fast for installation, time-saving;

6. Can supply products based on specific requirements;

7. Prompt delivery, high quality, competitive price and complete sets of style;

8. Can supply products based on specific requirements;

- Q: Construction works: light steel keel partition in a ceiling ceiling, the height should be calculated to the ceiling ceiling or calculated to the bottom of the concrete floor?

- When calculating the area of the ceiling, the cross section of the light steel keel shall be reduced.

- Q: Light steel keel ceiling calculation method

- Per square meter ceiling need: The main keel 1 meter, deputy keel 2 meters, stays up the keel 2 meters, while the keel for the ceiling around the total length (with the room size, shape). If you want to calculate in detail, it is necessary to see how the layout of the keel on the drawings. for example: The main keel spacing of 1.2 meters, along the length of the layout of the room; vice keel spacing 0.6 m; stays keel spacing 0.6 m; room length 6 m, width 4.5 m. The main keel is: 4.5 ÷ 1.2-1 = 2.75 (root), rounding requires three main keels, keel spacing adjusted to 4.5 ÷ (3 +1) = 1.125 meters. The main keel needs: 6 × 3 = 18 meters. Vice keel is: 6 ÷ 0.6-1 = 9 (root), keel spacing just to meet the design requirements of 0.6 meters. Vice keel need: 4.5 × 9 = 40.5 meters. Hold the keel is: 4.5 ÷ 0.6-1 = 6.5 (root), rounding requires 7 stays keel, keel spacing adjusted to 4.5 ÷ (7 +1) = 0.56 m. Hold the keel need to: 6 × 7 = 42 meters. Side keel need: (6 + 4.5) × 2 = 21 meters. In the material plan, each should also be added to the loss of 1 to 3% OK!

- Q: Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- Light steel keel is above the keel, the ceiling should use keel, gypsum board ceiling also use keel, generally with wood keel, of course, can also use light steel keel friends, to say that the price is light steel keel expensive.

- Q: Is this a ceiling that can be built? Use light steel keel gypsum board or wood keel? Trouble in detail under the construction process

- With light steel keel with three or four to mention the mention of the shape of it! Absolutely solid!

- Q: Light steel keel ceiling and wood keel ceiling What is the difference between ah! Which performance is better, the price difference is different! Ask everyone!

- Home decoration on the process requirements are higher.With the wooden keel to make the framework easy to correct .. so that the ceiling is not easy to deformation in the installation, after all, is the wood due to changes in the weather season, there will be hot up cold shrinkage. When the decoration is generally required for the wooden keel frame fixed. Fixed in the ceiling keel should be every 60 cm should play an expansion screw. The next well-shaped frame should be bayonet handle, gun nail fixed. Well shape frame every 30 cm The wood keel is a flammable material, no fire .. at the price of wood keel than light steel keel is higher .. now wood keel one meter at least 2 yuan. , Light steel keel need to be placed side by side .. Light steel keel because the specifications are too long, not suitable for use in the family, because the home decoration is not like a tooling decoration ceiling is a large area with light steel keel is drawn, The family can not draw, but also a reason is the family ceiling because the area is only part of the use of light steel keel is not to do. Must be the wooden keel frame can be .. so in the home decoration with wood keel is the best choice.

- Q: I help people pull the line, to climb the ceiling, but the ceiling of the light steel looks thin, you can climb up? Afraid! I am now 120 pounds.

- No, gypsum board is too brittle easy to rotten

- Q: Light steel keel gypsum board ceiling construction practices?

- The following is the approximate process, the specific process recommendations or need to look at the construction site to do. Pellet to determine the location of the hanging point - and then drill holes - install the hanging bar - and then install the main hook - install the main keel - install the sub-hanging - install the vice keel - install gypsum board - After the work of the painter. Which in the packaging gypsum board to do before the concealment project acceptance. Mainly light alignment must be accurate

- Q: Light steel keel ceiling hidden information, including what ah

- Electrical wiring, electric pipe threading and other electrical professional projects have been done;

- Q: Light steel keel ceiling cracks how to deal with

- There are many reasons for the cracking of the roof, and the repair of cracks caused by different causes is not the same. Therefore, after the cracks, the first should be how the cracks are generated, to identify the problem of pipe fittings, and then develop a rest plan, should not blindly construction. Otherwise it may fall into a crack, make up the vicious cycle of the process. There are three main reasons and treatment methods: 1, the surface of the paint surface cracking repair If only the ceiling film to generate linear, multi-angle or irregular cracks, then the problem is not very serious. The reason may be due to a brushing too thick or dry re-coated, the substrate is too loose or rough, primer and paint is not matched and so on. Repair measures: to eliminate the affected film; to ensure that the film is not a very thick construction; to ensure that the front paint dry after re-coating; if necessary, with the appropriate primer to seal the substrate; for roughness of the substrate, The use of good flexibility of the product; substrate temperature below 5 ℃, not construction latex paint; primer and finish to match. 2, the temperature changes caused by the ceiling cracking If it is due to temperature changes caused by cracking, generally appear in the surface, will not affect the safety of the ceiling, the surface can be processed about. 1, the gap is not: If the surface gap is not large, it is recommended in the gap posted a layer of kraft paper, and then brush the surface coating. 2, the gap is wide: If the surface gap is wide, then it is best to cut out a piece of gypsum board, polished into the appropriate shape, fill in the gap, and then brush the finish paint. 3, improper construction caused by the ceiling cracking if it is because the ceiling frame, gypsum board finishes, etc. ...

- Q: Light steel keel gypsum board ceiling lamp how to install

- This is not the most basic process? Cutter to open the downlight to buy the LED is the external spotlight effect is kind ~

Send your message to us

U-Shape Ceiling Profile System

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords