Ceiling Profile Metal Partition System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

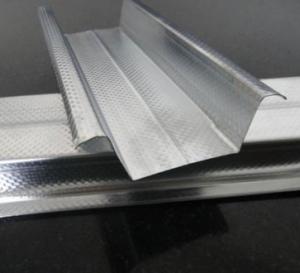

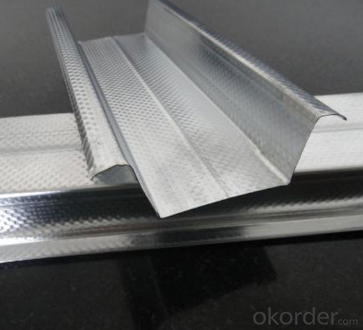

Steel Profile for Ceiling and Partition System

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q: Light steel keel ceiling hanging bar spacing how much?

- 30 cm to 40 cm between

- Q: Toilet integrated ceiling with good or good light steel keel good

- Of course the light steel keel is good. Wood keel gradually not used in the bathroom, the ceiling is not ventilated, a long time will be wet moldy. Reminded one, many brands of multi-grade ceiling, to their own to compare the choice of different stores.

- Q: Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- Light steel keel is above the keel, the ceiling should use keel, gypsum board ceiling also use keel, generally with wood keel, of course, can also use light steel keel friends, to say that the price is light steel keel expensive.

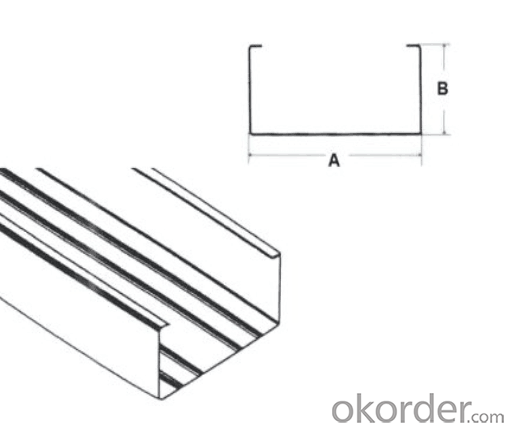

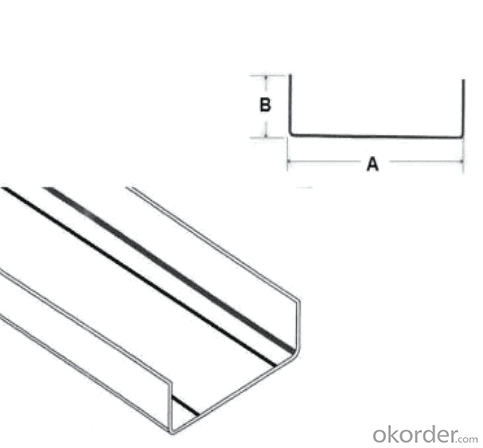

- Q: Ceiling light steel keel specifications are models which several

- Wall keel main specifications are divided into Q50, Q75, Q100 and Q150. Ceiling keel main specifications are divided into D38, D50 and D60 and so on. According to their cross-sectional shape is divided into U-type, C-type, T-type, H-type, V-type, L-type, CH-type seven, light steel keel mark the order: product name, code, cross-sectional shape of the width, Thickness and standard number. Customers should be based on process and decoration requirements, decided to use the wall keel, ceiling keel and specifications and cross-sectional shape.

- Q: What is the yellow water to the keel brush before making the light steel keel ceiling?

- To prevent corrosion of light steel keel rust ah.

- Q: I help people pull the line, to climb the ceiling, but the ceiling of the light steel looks thin, you can climb up? Afraid! I am now 120 pounds.

- No, gypsum board is too brittle easy to rotten

- Q: Light steel keel ceiling price 60 level probably need much money

- Gypsum board or aluminum plate or mineral wool board. The Up to 7000 or less. Minimum of 4000 or less

- Q: Light steel keel is a flat ceiling or integrated ceiling?

- Light steel keel skeleton is widely used in the decoration of the ceiling can use light steel keel skeleton But in order to facilitate the construction, often the ceiling keel will be used to other materials or the use of other materials and light steel keel construction

- Q: For example, the original requirement is 0.9 to 1.0 But actually made a 0.7, Is there any harm?

- Ceiling in the wood keel spacing: 1, light steel keel: keel for the edge of the dragon, the lamp slot position with keel or woodworking board production, there are wood production office to brush fire paint, keel at least 50, spacing 30cm is appropriate, hanging spacing 60-80cm is appropriate, gypsum Between the board and the board to be reserved for 5-8 mm gap, gypsum board self-tapping screws 1-2mm and do anti-embroidered treatment, to be smooth and solid, shaped to be smooth lines; 2, keel: keel at least 3 × 4 or more, spacing 30cm is appropriate, hanging spacing 60-80cm is appropriate, hanging bar is strictly prohibited direct use of wood wedge nail to the top, brush tight fire paint until the keel color can not see the dragon A layer of full-legged rice eucalyptus core after nine on the gypsum board, gypsum board and the board between the people to set aside 5-8mm gap, gypsum board self-tapping screws 1-2mm and do anti-embroidered treatment, to do To the formation of solid, shaped to do smooth lines; 3, aluminum buckle board: strict requirements level, light steel keel bayonet to be aligned, keel spacing of 50 or less, hanging spacing 60-80 cm is appropriate, the board when the hand to light, so as not to press the board, And the contact with the tile is not tight to use the sealant to play tight; 4, aluminum-plastic plate: keel at least 3 × 4 or more, spacing 30 cm is appropriate, hanging spacing 60-80cm is appropriate, brush tight fire paint, keel on a layer of full-legged rice eucalyptus core 9% Adhesive paste aluminum-plastic plate, aluminum-plastic plate between the board to be reserved for 3-4mm gap, prepared to fill other colors play the effect of sub-grid, to be smooth and solid, shaped to do smooth lines, folding The angle can not be broken.

- Q: Light steel keel paper gypsum board ceiling construction process

- Operating conditions 1. Construction of the structure should be in the cast-in-place concrete floor or prefabricated concrete floor slab, according to the requirements of the radio, according to the embedded φ6 ~ φ10 reinforced mixed boom, shot without the requirements of the arrangement of large keel location embedded steel hanging Rod, the general spacing of why 900 ~ 1200mm. 2. When the wall of the ceiling room for the brick masonry, the elevation should be in the ceiling along the walls and columns around the masonry embedded wood preservative, along the wall spacing 900 ~ 1200mm, the column should not be buried on each side More than two pieces of wood. 3. Install the roof of the various pipelines and ventilation ducts, to determine the light, ventilation and a variety of exposed mouth position. 4. All kinds of materials all ready to prepare. 5. Ceiling cover panel should be installed before the wall, wet operation project. 6. Take the roof construction platform. 7. Light steel skeleton roof in a large area before the construction, should do the model between the roof of the crown, lamp, vents of the tectonic treatment, block and fixed method should be tested and approved by the approved before the big Area construction.

Send your message to us

Ceiling Profile Metal Partition System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches