Lightgage Steel Joist Automatic Cold Roll Forming Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Brief Introduction of Our Company

Our company specializes in manufacturing cold-pressing steel profile mechanical equipment, cold-pressing structural section, high- frequency welding machine set, inert gas arc welding machine set, pipe bending machine, metal pipe circular saw machine, chamfering machine, pipe end forming machine, conveying appliance, elevator guide rail assistant processing equipment, dust-removing equipment, all kinds of conveying equipment parts and non-standard machinery products.

Fundamental functions of cold roll forming machine

The adjustable and speed changeable equipment is used to roll various kinds of profile materials. It uses decelerator to transmit each gear case in the main machine. The upper and lower two universal rotational axes on each channel drive each roller in arch frame to roll shaping. The number of forming lines is decided on the demand of sectional design or clients'. The line is equipped with automatic feeder and guide feeder. Adopting hydraulic pressure or pneumatic to realize automatic tracking cutting and unloading. It also adopted arbitrarily scale structural section of material receiving station and electric control system with synchronized movement.

Above-mentioned is our factory’s cold roll forming machine which has been manufactured. In this field, our factory has accumulated a great quality of equipments and mould materials. In no exceptional circumstances, our company can give you one package service including comprehensive technology, quality assurance, and reasonable price, finishing designing, creating, debugging and after-sale service. We are willing to deliberative discuss and cooperate with you about the exploitation of the varieties of profile steel. We are earnestly welcome you to our factory to have a field trip, we can offer you all kinds of product introduction and equipments technical reference.

Thickness: 0.15mm - 4.00mm

coil Width: 11mm-1500mm

Zinc coating: Z80 - Z275/m2

CID: 508 or 610mm

Standard: EN, JIS, GB

Grade: DX51D, SGCC, Cs-B, S280, S320, S350, S380, DQ, DDQ, Q195

Skinpassed: If required

Surface processing: Regular spangle, Minimized spangle, Zero spangle, bright spangle

Surface chemical processing: Chromate, un-chromate passivation and fingerprint resistant treatment;

slight oiled or non-oiled

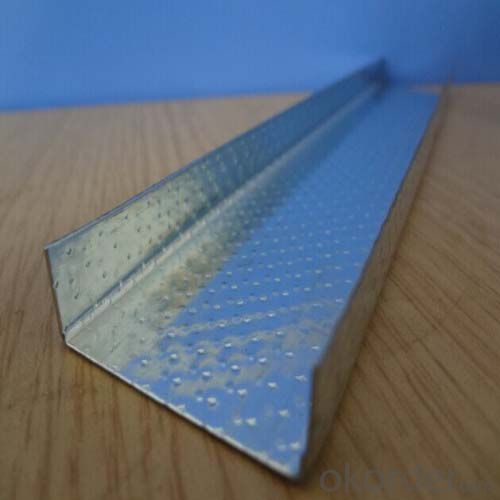

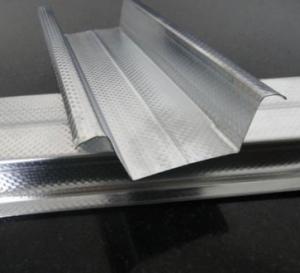

3.Image

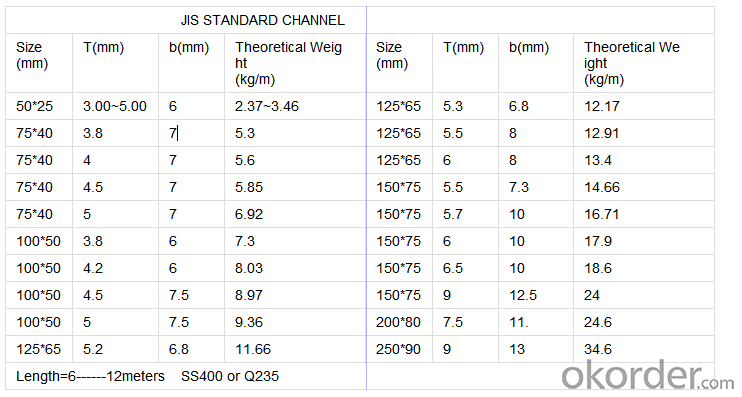

4.Detailed Specification

5.FAQ

Package: Standard seaworthy export packing.4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection. Outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection.

Usage: Galvanized steel coil products are mainly applied to building, light industry, automobile, agriculture and animal husbandry fishery . In construction industry, it is mainly used to produce anti-corrosion of industrial and civil building roof, roof grille. In light industries it can be used as appliances shell, civil chimney, kitchenware, etc Farming fisheries mainly used as food storage, the seafood frozen processing equipment of meat, Business mainly used as materials of storage, packing equipment etc..

- Q: Tectonic hierarchy of light steel keel

- Main machine The main equipment includes: saws, toothless saws, nail guns, hand saws, hand plane, pliers, screwdrivers, moving, square feet, steel ruler, steel level and so on.

- Q: Master ceiling should choose what specifications of light steel keel

- The main bone C60 is shown on the chart

- Q: Construction schedule of light steel keel ceiling

- 2 people, about 3 days. Good workers are faster

- Q: 140 square meters light steel keel double gypsum board ceiling fee, material costs about how much money

- That depends on whether you are hanging flat or modeling top friends. See you want to hang double gypsum board, then I will tell you according to the price of flat top, package package material monolithic gypsum board ceiling 80 yuan / square or so, the wages of each place is different, plus a layer of plaster Board 20 dollars / square to the top, because a gypsum board is 2.88 square feet, the price is twenty or thirty dollars, the other to send you a little advice: ceiling with a screw must use 8-10mm, can not use 6mm

- Q: Ceiling twenty square meters need light steel keel how many roots

- Light steel keel ceiling material ratio does not have a standard number, generally according to the shape of the room, height related.

- Q: Light steel keel ceiling material calculation method?

- Plate in square meters, gypsum board for 3 m * 1.2 m / per, ceiling area divided by the area of each gypsum board is the number of gypsum board used, the appropriate put some loss. The main keel per square meter with one meter can be calculated, pay keel per square meter with 3 meters, the boom calculated by two per square meter, the length of the floor height in accordance with the height of the ceiling can be reduced. Suspension fixed parts according to the number of boom configuration, hanging pieces of each square meter 2 calculation, with the number of boom. Hanging by 3-4 per square meter can be. The total number multiplied by the total area can be summed up, plus wealth can be

- Q: PVC plastic buckle plate ceiling with what keel ah?

- Local cracking Gong Guan folder pull the locust control Weihai even reason is the gypsum board between the seam is not handled well, no slot, no seam, seal gypsum is not dense, not paste the zipper and so will lead to cracking, when the hanging bar Not vertical, or hanging length of more than 1.5 meters and no anti-support, it will lead to local cracking. The quality of the main bone bones with the specifications of the construction are the factors that affect the cracking of gypsum board or not. Plaster layer off for many reasons, there are common plaster layer of the thickness of each layer is too thick, the grass is not dealt with the beginning of the batch of ash, the space is too large, the former plaster layer is not dry on the next wipe Gray, are the cause of the plaster layer off.

- Q: Light steel keel ceiling ,,, Commonly used is 50 to 50 system ,,, Light steel keel, the surface after the heat crossing zinc treatment, and long no rust, no deformation ,,, State regulations installed on the light steel keel on the gypsum board, as a class A fireproof material Wood keel because the water is too large, and love deformation ,,, no fire, so you can see Large place, no one is covered with wooden keel. The There are two real problems: 1 "with wood keel, the effect is not bad, and the cost is not cheap ,,, now light steel 50 keel and 3 * 5 wooden cost

- Light steel keel can be down from the roof down 1-2 meters, for the air conditioning, fire, communication, weak left there are maintenance mouth ,,, people can stand on the light steel keel repair equipment (at this time, the main keel must be 60 main dragon 60 * 27 * 1.2MM), This is the wood keel will never be able to do Before ,,, home decoration because the construction is relatively small ,,, hanging under the back and very small, so the carpenter with the wooden side . But the improvement of living standards ,,,, the use of light steel keel is a big trend ,,,,, in foreign countries are doing so Domestic, many of the current decoration company, also used the light steel keel ,,, I know that OKorder is the East Yi Sheng, ,, Long hair ,,,,, 3> light steel keel can make a variety of modeling roof, wood keel can not do ,,, is done, the effect is very bad ,,, 4> light steel keel construction fast ,,, good maintenance ,,,,

- Q: Light steel keel gypsum board ceiling artificial materials about how much money a square meter

- Light steel keel ceiling material costs about 40. Keel 'gypsum board GB and non-standard price gap, depending on your choice. Labor costs flat about 35, modeling top 50-60 a square, depending on the specific complexity.

- Q: Which is more cost-effective, want to get a professional answer Oh, anxious decoration it

- Certainly light steel keel wood keel is not fire waterproof

Send your message to us

Lightgage Steel Joist Automatic Cold Roll Forming Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords