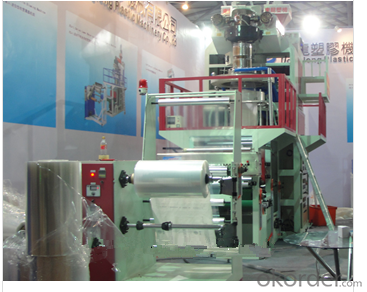

Two-layer Down-ward Water-cooled PP Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy Wooden Pallet |

| Delivery Detail: | 60 days after receiving the deposit |

Specifications

PP film blowing machine`s product features with good insulation,hot-sealing,low temperature resistance, mechanical performance

FEATURES:

1) This Water-cooled PP Film Blowing Machine Combined machine head with two-layer extrusion, lower blowing water (rapid) cooling, rotation of mould head

2) Good insulation, sealing, transparency, cooking, fresh-keeping, hot-sealing, and printing and other performance

3) The product produced by the machine features with good insulation, hot-sealing, low temperature resistance and mechanical performance.

Model | 2G-XSJ45/45-FMJ800 | 2G-XSJ55/55-FMJ1000 | 2G-XSJ65/65-FMJ1200 |

Max. Folded Film Width | 700mm | 800mm | 1000mm |

Film Thickness | 0.02~0.12mm | 0.02~0.12mm | 0.02~0.12mm |

Output | 60kg/h | 80kg/h | 100kg/h |

Raw Material | PP,LDPE,LLDPE | ||

Screw Diameter | 2XΦ45mm | 2XΦ55mm | 2XΦ65mm |

Screw L/D | 228:1 | 228:1 | 228:1 |

Total Power of the Machine |

~73kw |

~88kw |

~103kw |

Shape Size(LxWxH) | 6.0x1.8x4.0m | 6.7x2.5x4.5m | 7.2x3.0x5.0m |

Weight | ~4500kg | ~5700kg | ~6500kg |

Correct specifications depend on the actual model all spcifications are subject to change without prior notice | |||

- Q: What is the reason for the fuel injection of the turbine vacuum pump?

- 2, the vacuum tank discharge oil blocked or poor drainage, resulting in the vacuum tank oil level is too high. 3, oil filter just cast, internal accumulation of gas is too much, generally over a period of time (about 10 minutes later) just fine, so just put into the small oil pump outlet valve and vacuum pump inlet valve, and then gradually opened.

- Q: What is the difference between an oil filter and an edible oil refinery? Is it the same device? How about the price? Is it a big difference? I want to buy one useful,Good to Luhua peanut oil level. Please give me your advice. Thank you very much.

- Some impurities in the oil refining equipment used to filter the main removal generally need to go through six to reach the standard and edible oil a large edible oil refining equipment at least tens of millions of millions of expensive harmful ingredients in oil refining

- Q: How to choose insulating oil vacuum filter

- 3, the safety interlock protection system, interaction of oil inlet and heating device and infrared liquid level control system, pressure protection device, thermal protection and safety shut-off valve, to avoid the adverse effects caused by misoperation, protect the safety of the machine.4, on-site insulation treatment of insulating oil, purification of all types of degradation of insulating oil has special effects.5, environmental protection chassis structure design, reduce environmental pollution. Good mechanical strength, acid and alkali resistance, long service life. Satisfy the indoor and outdoor use environment.6, according to the needs of the design, the use of PLC automatic control, with touch-screen dynamic display, can be networked with the computer to operate, to achieve high intelligence.

- Q: How much is the 90 screw frying machine?

- The following aspects mainly determine the price of the oil press.Screw oil press diameter, diameter, the greater the speed of work, the higher the price.

- Q: Why is the oil filtered out of the oil filter cleaner?

- The oil filter can only filter the impurities and moisture in the oil

- Q: What are the 3 basic requirements of hydraulic system for hydraulic oil filters?

- We have used hydraulic oil filters, three basic requirements, one is to select the flow rate suitable for hydraulic oil filter

- Q: Application of vacuum oil filter

- The common transformer oil vacuum oil filter also has the function of vacuum oiling and live on-line operation. 4. Trinity interlock and protection device. 5. can randomly detect the value of resistance, and automatically print the test results (usually for purchase items)

- Q: How can I get rid of the cooking oil and the sediment filtered out by centrifugal oil filters?.

- An oil filter is a filter device for removing mechanical impurities, byproducts and moisture in impure oil by gravity, centrifugal, pressure, vacuum distillation, mass transfer and other techniques. Oil filter is mainly used to improve the cleanliness of machinery and electrical oil, so as to give full play to the best performance and extend the service life of equipment.

- Q: What kind of oil can the oil filter handle?

- Only 1, ordinary oil filter cleaning and removal of micro water, such as frame type oil filter, oil filter machine, portable portable oil filter, can handle the oil is usually low viscosity lubricating oil, hydraulic oil, this kind of equipment can also be used as fuel for oil.

- Q: Consult an expert, power plant turbine oil vacuum filter oil machine, why use ah, seems to be useful, poly junction separation, what are the advantages and disadvantages, thank you, urgent,

- Turbine oil vacuum oil filter can remove the dissolved water in oil (about 150mg/L) and non dissolved water (more than 150mg/L will have, that is, the tiny drops of water) in oil water content reduced to below 50mg/L, but if the oil with high water content, the dehydration rate is relatively slow. Beijing instant Technology Co., Ltd. turbine oil vacuum oil filter is a new technology, new products, it is recommended concern

Send your message to us

Two-layer Down-ward Water-cooled PP Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches