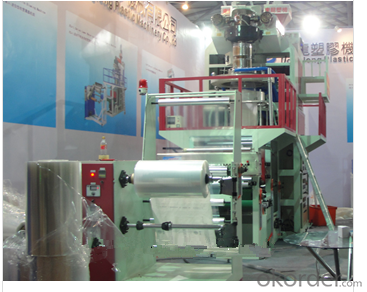

CMAX High Output Two-layer Co-extrusion Down-ward Water-cooled Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy Wooden Pallet |

| Delivery Detail: | 60 days after receiving the deposit |

Specifications

PP film blowing machine`s product features with good insulation,hot-sealing,low temperature resistance, mechanical performance

FEATURES:

1) This Water-cooled PP Film Blowing Machine Combined machine head with two-layer extrusion, lower blowing water (rapid) cooling, rotation of mould head

2) Good insulation, sealing, transparency, cooking, fresh-keeping, hot-sealing, and printing and other performance

3) The product produced by the machine features with good insulation, hot-sealing, low temperature resistance and mechanical performance.

Model | 2G-XSJ45/45-FMJ800 | 2G-XSJ55/55-FMJ1000 | 2G-XSJ65/65-FMJ1200 |

Max. Folded Film Width | 700mm | 800mm | 1000mm |

Film Thickness | 0.02~0.12mm | 0.02~0.12mm | 0.02~0.12mm |

Output | 60kg/h | 80kg/h | 100kg/h |

Raw Material | PP,LDPE,LLDPE | ||

Screw Diameter | 2XΦ45mm | 2XΦ55mm | 2XΦ65mm |

Screw L/D | 228:1 | 228:1 | 228:1 |

Total Power of the Machine |

~73kw |

~88kw |

~103kw |

Shape Size(LxWxH) | 6.0x1.8x4.0m | 6.7x2.5x4.5m | 7.2x3.0x5.0m |

Weight | ~4500kg | ~5700kg | ~6500kg |

Correct specifications depend on the actual model all spcifications are subject to change without prior notice | |||

- Q: The oil filtered by a vacuum oil filter is then placed in a centrifugal oil filter and filtered without salt water

- No, vacuum filtration only filters the sludge in the oil and does not filter out the phospholipids in the oil

- Q: What's the name of the glass tubing that filters the oil-water separation?

- Liquid level meter, you can clearly see the oil and water stratification.

- Q: What's the difference between an oil filter and an oil press?

- The main function of the oil filter is to filter the impurities in the oil and remove moisture, the higher point can also adjust the pH of the oil, etc., and the oil press usually refers to the extraction of oil from the plant through physical processes.

- Q: Is the temperature of the Kato vacuum pump casing working high and normal?

- Breaking oil solenoid valve, or coil damage or electromagnetic valve diaphragm rupture or aging, oil breaking solenoid valve generally appear in the old models;Cooling fan motor fault;The exhaust duct is not unblocked or the exhaust resistance (back pressure) is large;The ambient temperature exceeds the specified range (38 degrees C or 46 degrees C).Hope to be of help to you.

- Q: What is the selection of the oil filter for the turbine?

- In addition, you are centralized filtration (that is, putting all the steam turbine waste in one place to filter), or on-line filtering will also affect the selection of the flow rate of the oil filter. For example, you centralized filtration, large amount of oil, if you request a day after the filtering, it must be 100 liters per minute or more, if you want to waste online filtration cycle, then certainly not centralized so high, so we can choose small flow. Also, look at your filter time requirements,

- Q: Oil filter HNP021-380-50-K-Z what does that mean?

- The 021 is usually produced in the factory number or date inside the company; the 380 is that the oil filter of the power is 380V, that is to say the oil filter of the power supply is 380V; 50 generally refers to the size of the flow of 50 liters per minute per hour or 50KG; K generally refers to the oil filter, according to the meaning, should refer to the anti fuel, which means that the oil filter is to filter the anti fuel (of course, may also have a fast and efficient filter means), Z generally refers to the vacuum oil filter, filter water.

- Q: What kind of scheme is better for the oil filter except the impurity?

- 4, vacuum oil filter, the principle is to use the principle of vacuum removal of water in the oil, the use of fine filter cartridge to remove impurities in the oil. The utility model has the advantages of good water removing effect, good impurity removing effect, stable operation of the system and no need for human care. Before now, the oil filter is basically one of the best. However, the selection of such oil filter equipment, there is a great deal of attention. Because the capacity of vacuum water removal is affected by the area of the vacuum separator in the oil filter. Theoretically, the greater the area of the vacuum separator, the better the effect of water removal, but because of the limited size of the equipment, so the vacuum separator will not continue indefinitely. So the chance of high quality vacuum oil filter in the vacuum separator, vacuum separation device in the Lv of the same area, who use the high technology (equivalent to the increase of vacuum separator area), oil filter whose effect will be better. This is also the choice

- Q: Who knows what the vibration of the oil filter is?

- You are welcome. We will do our best to help you with the oil filter. We will be the manufacturer of the oil filter

- Q: Characteristics of vacuum oil filter

- 5. It can also be used in power plants, power plants, power companies, power transformation industry, metallurgy, petrochemical, machinery, transportation, railway and other industries. PSDZJ series vacuum oil filter product overview PSDZJ series vacuum oil filter is the ideal equipment for the maintenance department of the electric power field to inspect and repair all kinds of high and low voltage (500KV or less) insulation oil for power transmission and transformation equipment. The series of products, easy to move, the technical indicators reached the advanced level of domestic similar products, some of the indicators in the leading domestic level, the use of closed oil filtering methods. Can live working, can dry the moisture in the transformer and other equipment, widely used in power plants, industrial and mining enterprises and purification of transformer oil, turbine oil, hydraulic oil, transformer oil, transformer oil, water switch frozen oil in the oil, gas and impurity particles. PSGLJ series light precision filter product overview PSGLJ series light precision filter is mainly used for special types of impurity, oil fine filter solid lubricating oil, insulating oil etc., especially high viscosity oil filter to filter the ordinary oil filter. It is the replacement product of plate and frame pressure filter. The only mechanical impurity filtering occasions, compared with the vacuum oil filter is more flexible and convenient, low cost, and high accuracy, than the ordinary pressure type filter of wide application, long service life, can be heated to reduce viscosity, do not need to replace the filter paper, filtering accuracy and stability

- Q: Does the vertical centrifugal oil filter have any residue in the filtered oil?

- See what oil you want to filter, and then choose the oil filter is better

Send your message to us

CMAX High Output Two-layer Co-extrusion Down-ward Water-cooled Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords