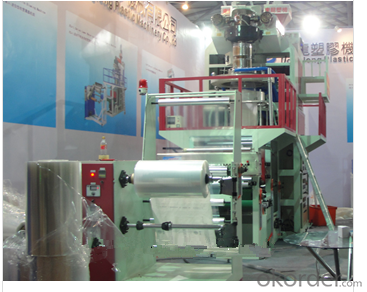

CMAX Two-layer Co-extrusion Down-ward Water-cooled PP Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy Wooden Pallet |

| Delivery Detail: | 60 days after receiving the deposit |

Specifications

PP film blowing machine`s product features with good insulation,hot-sealing,low temperature resistance, mechanical performance

FEATURES:

1) This Water-cooled PP Film Blowing Machine Combined machine head with two-layer extrusion, lower blowing water (rapid) cooling, rotation of mould head

2) Good insulation, sealing, transparency, cooking, fresh-keeping, hot-sealing, and printing and other performance

3) The product produced by the machine features with good insulation, hot-sealing, low temperature resistance and mechanical performance.

Model | 2G-XSJ45/45-FMJ800 | 2G-XSJ55/55-FMJ1000 | 2G-XSJ65/65-FMJ1200 |

Max. Folded Film Width | 700mm | 800mm | 1000mm |

Film Thickness | 0.02~0.12mm | 0.02~0.12mm | 0.02~0.12mm |

Output | 60kg/h | 80kg/h | 100kg/h |

Raw Material | PP,LDPE,LLDPE | ||

Screw Diameter | 2XΦ45mm | 2XΦ55mm | 2XΦ65mm |

Screw L/D | 228:1 | 228:1 | 228:1 |

Total Power of the Machine |

~73kw |

~88kw |

~103kw |

Shape Size(LxWxH) | 6.0x1.8x4.0m | 6.7x2.5x4.5m | 7.2x3.0x5.0m |

Weight | ~4500kg | ~5700kg | ~6500kg |

Correct specifications depend on the actual model all spcifications are subject to change without prior notice | |||

- Q: What is the working vacuum in the oil filter?

- The existing vacuum oil filter machine technical indicators only vacuum oil filter and coalescence vacuum oil filter two, so to answer this question, you need to understand the principle of vacuum oil filter, vacuum oil filter machine work, need to vacuum oil filter in the outside atmospheric pressure and oil filter in the vacuum pump under the action of the suction filter, large particle impurities are removed by the oil heater into the precision filter, filter the impurity particles fine before entering the water filter, separated out from the oil droplet, the precipitation in the water reservoir. The oil solution for removing impurities and large water drops enters a three-dimensional vacuum flash tower for further treatment of micro water.

- Q: How to solve the oil press foam?

- The reason for the foaming is that the oil contains phospholipids, so long as you filter it out

- Q: Transformer oil filter how to choose?

- Our company is also transformer oil inlet, according to our oil situation, the choice is a two stage transformer oil vacuum oil filter, after use, there is a great improvement

- Q: Plate and frame filter press VS centrifugal oil machine competition, who is better?

- High speed centrifugal oil filter is based on the principle of centrifugal force to remove pollutants in lubricating oil, the oil will effect on pump into the centrifuge rotating hub, the hub pressure reached 0.4-0.7MPA pressure inside the centrifuge through a double rotor, the instant release of pressure, driving in high speed rotation of rotor.

- Q: What are the 3 basic requirements of hydraulic system for hydraulic oil filters?

- Three is based on their own circumstances to choose the right configuration. If not clear, you can go to ask a manufacturer to know

- Q: Who knows what the vibration of the oil filter is?

- Generally, the vibration of oil filters is very harmful: vibration, noise, accelerated wear of bearings, shortening of mechanical life, and serious damage accidents.There may be four reasons:1, the anchor screws loose. Solution: just tighten it2, the uneven thickness of sludge. Solution: clean the residue

- Q: Consult an expert, power plant turbine oil vacuum filter oil machine, why use ah, seems to be useful, poly junction separation, what are the advantages and disadvantages, thank you, urgent,

- Turbine oil vacuum oil filter can remove the dissolved water in oil (about 150mg/L) and non dissolved water (more than 150mg/L will have, that is, the tiny drops of water) in oil water content reduced to below 50mg/L, but if the oil with high water content, the dehydration rate is relatively slow. Beijing instant Technology Co., Ltd. turbine oil vacuum oil filter is a new technology, new products, it is recommended concern

- Q: How many filters are there in the portable oil filter? What's the difference?

- Three is the three filter in parallel, and the four is the 4 filter, in turn, but double two start, each filter precision is different, this should be based on the filter medium to decide.

- Q: Operating principle and characteristics of electrostatic oil filter

- The impurity particles less than 0.1 M can be effectively removed, and the filtering accuracy is high. After many cycles of filtration, the cleanliness of the oil can be kept at NAS1638:5--8 level without clogging. Suitable for precision hydraulic system with servo system

- Q: How is the plate type oil filter put into operation?

- I'm not sure what you are asking. This is specific. You can ask Taizhou HUAWEI. They have been making oil filters for many years

Send your message to us

CMAX Two-layer Co-extrusion Down-ward Water-cooled PP Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches