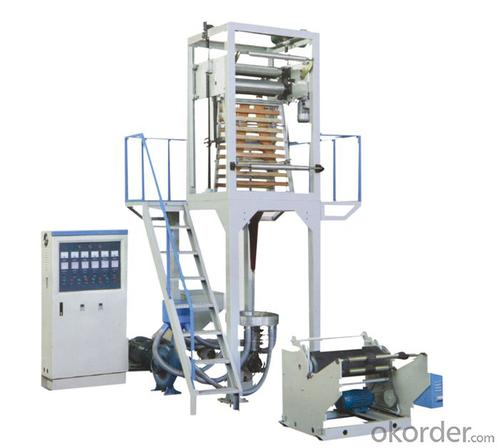

Plastic PE Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

It is suitable for blowing the plastic film as high density polyethylene

(HDPE),low density polyethylene(LDPE) and linear low density

polyethylene(LLDPE),which is widely used for packing foodstuff,

garment,textile,daily-use articles and industrial products etc.It can

produce pearl film and degradation film via making up a prescription.

Characteristics:

1.The screw stem and cylinder are made of 38CRMOALA highquality alloy steel affer fine finishing and nitrided treatment,whichhas high hardness,strong resistance to corrosion,durable service.

2.The die head is plated with hard chrome,of screw mandrel

type structure with even and smooth discharging,the blown plastic

film has fine finishing

3.The blower is of labyrinth structure with even air output.

4.The winding unit adopts friction pressure rewinding or center

rewinding, which is driven by torque motor,with even and easy roll

changing.

Main Technical Parameter

MODEL | 45 | 50 | 55 | |||

SUITABLE MATERIAL | HDPE ,LDPE, LLDPE | |||||

FILM WIDTH (mm) | 800-1300 | 800-1500 | 1200-2000 | |||

FILM THICKNESS(HD) mm | 0.028-0.18 | 0.028-0.18 | 0.028-0.18 | |||

MAX EXTRUSION OUTPUT | 80-130kg/hr | 120-190kg/hr | 150-260kg/hr | |||

EXTRUDER | ||||||

SCREWDIAMETER (mm) | 45/50/45 | 50/55/50 | 55/65/55 | |||

SCREW L/D LENGTH | 28:1 | |||||

SCREW AND CYLINDER MATERIAL | SACM-645/38 CRMOALA | |||||

CYLINDER COOLING | 370W×2 /3 | 370W×2 /3 | 550W×2/3 | |||

TEMPERATURE CONTROL | 3X3 | 3X3 | 3X3 | |||

Average power-consume | 58kw | 70kw | 90kw | |||

MAIN MOTOR(KW) | 15/18.5/15 | 18.5/22/18.5 | 22/37/22KW | |||

TYPE OF DIE | ||||||

DIE SIZE (mm) | 200/250 | 250/300 | 350/400 | |||

Temperature control | 4 | |||||

AIR RING | 1 | |||||

Air blower | 5.5kw | 7.5kw | 11kw | |||

TAKE UPUNIT | ||||||

ROLLER WIDTH(mm) | 165×1400 | 165×1600 | 190×2100 | |||

TAKE-UP SPEED | 5-60m/min | 5-60m/min | 5-60m/min | |||

Take-up motor | 1.5KW | 1.5KW | 2.2KW | |||

WINDING UNIT | ||||||

Type | Surface friction type | |||||

Winding motor | 1.5kw | 1.5kw | 2.2kw | |||

Winding speed | 5-60m/min | 5-60m/min | 5-60m/min | |||

OVERALL DIMENSION(LXWXH) | 7.5x5.5x7m | 8.2X5.8x7m | 9X6.4X8.2 m | |||

Chnical Parameter:

MODEL | CW-3HL45 | CW-3HL50 | CW-3HL55 | |||

SUITABLE MATERIAL | HDPE ,LDPE, LLDPE | |||||

FILM WIDTH (mm) | 800-1300 | 800-1500 | 1200-2000 | |||

FILM THICKNESS(HD) mm | 0.028-0.18 | 0.028-0.18 | 0.028-0.18 | |||

MAX EXTRUSION OUTPUT | 80-130kg/hr | 120-190kg/hr | 150-260kg/hr | |||

EXTRUDER | ||||||

SCREWDIAMETER (mm) | 45/50/45 | 50/55/50 | 55/65/55 | |||

SCREW L/D LENGTH | 28:1 | |||||

SCREW AND CYLINDER MATERIAL | SACM-645/38 CRMOALA | |||||

CYLINDER COOLING | 370W×2 /3 | 370W×2 /3 | 550W×2/3 | |||

TEMPERATURE CONTROL | 3X3 | 3X3 | 3X3 | |||

Average power-consume | 58kw | 70kw | 90kw | |||

MAIN MOTOR(KW) | 15/18.5/15 | 18.5/22/18.5 | 22/37/22KW | |||

TYPE OF DIE | ||||||

DIE SIZE (mm) | 200/250 | 250/300 | 350/400 | |||

Temperature control | 4 | |||||

AIR RING | 1 | |||||

Air blower | 5.5kw | 7.5kw | 11kw | |||

TAKE UPUNIT | ||||||

ROLLER WIDTH(mm) | 165×1400 | 165×1600 | 190×2100 | |||

TAKE-UP SPEED | 5-60m/min | 5-60m/min | 5-60m/min | |||

Take-up motor | 1.5KW | 1.5KW | 2.2KW | |||

WINDING UNIT | ||||||

Type | Surface friction type | |||||

Winding motor | 1.5kw | 1.5kw | 2.2kw | |||

Winding speed | 5-60m/min | 5-60m/min | 5-60m/min | |||

OVERALL DIMENSION(LXWXH) | 7.5x5.5x7m | 8.2X5.8x7m | 9X6.4X8.2 m | |||

- Q: Where is the vacuum oil purifier repaired?

- Then there is a problem with the pump, the pump needs to be repaired.Find a supplier to repair it

- Q: Pneumatic oil filter is slow, isn't it too low?

- Vacuum filter oil filter slow, there are the following reasons: excessive impurities, filter plug

- Q: Use vacuum oil filters to filter transformer oil in summer and winter temperature should be in the degree of the northern region

- Based on the increase of summer to meet a set of manual heating in winter, under the condition of different voltage levels, the design of oil filter is also different, must meet a variety of needs, when filtering, just put the oil filter of the temperature can be set in 55-60 (oil temperature in more than 60 after the temperature, every increase of 10 degrees, the oxygen speed is doubled, in the process of paying special attention to the temperature control in the process of light oil, and more attention should be paid to this), the temperature is in the factory set up, the instructions have specific instructions, only in accordance with the rules of operation manual operation OK

- Q: Where can I get a good oil filter?

- 1, to buy oil filter must first understand what is the oil filter, what is the function and effect, and the relevant background knowledge, and then query or search for information about the current oil industry some leading enterprises such as what company. Only roughly know clearly that we can roughly grasp the manufacturers of oil filter oil filter, power price, otherwise it is smoke and mirrors, puzzled, what is what others say. Especially in the current oil filter industry, the majority of small and medium enterprises, this kind of supporting industries, but also be careful. Non-standard small industry, the water is very deep, disorganized, disorderly development, it is easy to sell shoddy products.2 、 oil filter is an auxiliary type of non-standard machinery, mainly used for industrial oil or cooking oil, here mainly on industrial oil filter. Many kinds of industrial oil, most of the functions are lubrication, reduce friction and temperature, antifreeze, anti rust, insulation, hydraulic, widely used in industry, various applications, therefore, the industry developed oil filter oil filter the corresponding machine according to different application scenarios, convenient for users to choose. The oil filter from the technical angle, mainly vacuum oil filter, filter bag, trolley type oil filter oil filter, oil filter, pressure plate type centrifugal oil filter, electrostatic oil filter, ceramic filter and so on, in front of several popular on the market, after several major for special industries, cost high, most users can not touch on.

- Q: Hydraulic press to buy automatic integration of good or alone to buy the right?

- The split oil filter is an enlarged oil filter, in contrast to an integral oil filter, the split oil filter is faster.In addition, different oil filters are arranged for different press processes and press methods, not only vacuum oil filters.Therefore, stand-alone configuration is better than one configuration.

- Q: Want to produce oil filter, that is to filter the hydraulic oil machine. I don't know. Is that ok? The accuracy can reach 2 microns, 5 microns, 10 microns, 20 microns, 40 microns, please

- 4 answersForget it!! Want to do well in the oil filter, now demand plummeted, large manufacturers, like our Chongqing runneng oil filter, oil filter such enterprise development more than 10 years machine get up have labored, small factories had more bad days!

- Q: What happens when the oil heater is fired and the heater is tripped?

- With a universal watch to see the damping of the ground and heating rod damping, general leakage will trip, and there is open good and bad, useless, the naked eye to see the bad and bad probability is too small, must use table

- Q: Oil filter ZLA-20! During the test process! Foam! How can you remove the foam?! I'll vacuum it a little bit, and the bubble will be better! however

- It's the ZLA-20 filter produced by the garbage manufacturer, so you can settle for them

- Q: Working principle and operation instructions of vacuum oil filter for oil press

- Vacuum pump to vacuum tank air to form a vacuum, outside the oil under the influence of the atmospheric pressure through the entrance pipe into the primary filter, remove larger particles, and then into the heating tank, heated by 40 degrees to 75 degrees of oil through the automatic oil float valve, this valve is automatic control into the vacuum tank of oil import balance, after heating the oil whirl through the spray wing separating oil into a mist, oil and water in the rapid evaporation of water vapor into the vacuum pump and continuous inhalation of condenser.

- Q: Is the pressure type oil filter better than the vacuum oil filter?

- The pressure type oil filter doesn't have a vacuum oil filter

1. Manufacturer Overview

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic PE Film Blowing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords