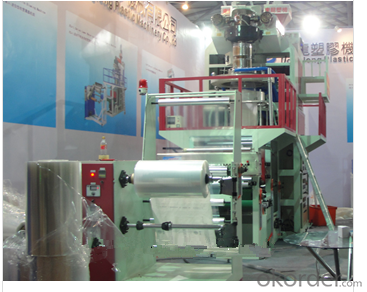

Two-layer Co-extrusion Down-ward Water-cooled PP Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy Wooden Pallet |

| Delivery Detail: | 60 days after receiving the deposit |

Specifications

PP film blowing machine`s product features with good insulation,hot-sealing,low temperature resistance, mechanical performance

FEATURES:

1) This Water-cooled PP Film Blowing Machine Combined machine head with two-layer extrusion, lower blowing water (rapid) cooling, rotation of mould head

2) Good insulation, sealing, transparency, cooking, fresh-keeping, hot-sealing, and printing and other performance

3) The product produced by the machine features with good insulation, hot-sealing, low temperature resistance and mechanical performance.

Model | 2G-XSJ45/45-FMJ800 | 2G-XSJ55/55-FMJ1000 | 2G-XSJ65/65-FMJ1200 |

Max. Folded Film Width | 700mm | 800mm | 1000mm |

Film Thickness | 0.02~0.12mm | 0.02~0.12mm | 0.02~0.12mm |

Output | 60kg/h | 80kg/h | 100kg/h |

Raw Material | PP,LDPE,LLDPE | ||

Screw Diameter | 2XΦ45mm | 2XΦ55mm | 2XΦ65mm |

Screw L/D | 228:1 | 228:1 | 228:1 |

Total Power of the Machine |

~73kw |

~88kw |

~103kw |

Shape Size(LxWxH) | 6.0x1.8x4.0m | 6.7x2.5x4.5m | 7.2x3.0x5.0m |

Weight | ~4500kg | ~5700kg | ~6500kg |

Correct specifications depend on the actual model all spcifications are subject to change without prior notice | |||

- Q: I would like to ask the following prawns, oil filters to do the sale, which customers should be running or units?

- Don't tell me can vacuum oil filter with high precision deimpurity ah, the wire net can be useful not pull, and now the electrostatic oil filter, high precision oil filter, membrane filtration, centrifugal oil filter, too much, which each have a lot of technology, too much,

- Q: How to assemble and disassemble the vacuum pump for power generation oil filter?

- After the warranty period if you can point out the money and allow them to install, if they don't want to come, let them call instruction, could not provide service, customer service, customer service service are not even, such companies also want to do

- Q: What is the optimum oil temperature of vacuum oil filter?

- 3. when the vacuum reaches -0.08Mpa, open the intake valve 15 to make it into the oil.

- Q: The working principle of vacuum oil filter and centrifugal oil filter in oil filter and the difference between them

- 1., the filter oil function at the same time to complete high content dehydration and deep dehydration, in addition to impurities, de gum, demulsification, acid removal, decolorization, oil refining function;2., it has the combined functions of molecular filtration, condensation dehydration, box filtration, pressure filtration, vacuum deep drying and so on;3. oil filter adopts fuzzy control technology. It runs reliably and has long service life. It has the functions of pressure overload protection, automatic anti dry burning, automatic defoaming and automatic oil level control;4. oil filter with cooling water tank, self cooling cycle;5., oil filter function and unit synchronous online purification, on-line (do not have to destroy the vacuum) discharge separate water;

- Q: Can oil filter oil filter oil still be used?

- It depends on the performance of the oil filter. If it can be standardized to filter dehydration, it can be used in an industrial environment.

- Q: Why does the oil filter run out of vacuum? How can we solve it?

- So, how to solve the phenomenon of traditional injection vacuum pump oil filter, please refer to the following solutions: 1.) the cause of the accident to be treated in the oil liquid, containing dissolved gas and air solution) to high vacuum oil filter equipment operating in the semi vacuum, until the gas content decreased until 2. the cause of the accident) required for processing and solve the oil temperature too low foaming method) oil to improve the operation of the equipment accident causes oil 3. part cycle) due to oil pump failure or blockage of the vacuum separator is not discharged oil solution) to check the pump and vacuum pump, depending on the need for cleaning or repair the cause of the accident 4.)

- Q: Zjcq-4 vacuum oil purifier starts several seconds later, how to deal with unbalanced three-phase current and broken phase?

- Oil filter is not cabbage, sold regardless of ah, if you encounter, indicating that you buy small manufacturers! In the past, our company bought the Chongqing Ashton, when the motor burned, a phone call to them, is not coming, dare not come?

- Q: How many kinds of transformer oil vacuum oil filters are available?

- These four kinds of vacuum oil filter models of each manufacturer have different definitions, here can give some models according to the national standard, high vacuum oil filter - ZJB; double stage vacuum oil filter and oil processing UHV vacuum oil filter called ZJA, regeneration type vacuum oil filter are called ZYB. In these models are based on the vacuum oil filter size and the size of the flow according to distinguish, there are two kinds of common, and how many liters per minute per hour cubic, such as 30L/min, /1H and so on 0.5 square meters

- Q: How does the 25 litre oil purifier determine flow?

- 3., oil precision (this also takes into account the specific requirements of the company's oil) 4. price and quality (which is each purchaser should consider) 5. aftermarket now oil filter, one can filter a variety of oil

- Q: Comparison of performances of several oil filters

- Features: good effect of oil - containing water on the separation effect of the separation of impurities; the oil is poor; it needs to be equipped with precision filter to filter out impurities; the installation and maintenance is troublesome,.4 ionization type oil filter is using the electric field intensity of water droplets, to weaken the strength of interfacial film. The water droplets collision coalesce into large particles, sedimentation and separation. Features: good - containing water on the separation of oil - water separation effect; the oil rate is low when the effect is poor; the demulsifying ability is not very strong,.5 coalescence type oil filter is based on the latest oil coalescence and separation principle as the basis liquid filtration and dewatering equipment. It has the features: high precision filtration, high efficient dewatering, good filtering effect; the demulsifying ability is very strong; the impurity removal effect is very good, and is suitable for high oil content in the purification of large and small flow system; the flexible movement, operation Quick and easy (one button start), free of maintenance

Send your message to us

Two-layer Co-extrusion Down-ward Water-cooled PP Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches