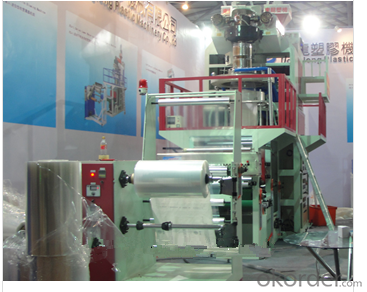

Two-layer Co-extrusion Down-ward Water-cooled Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy Wooden Pallet |

| Delivery Detail: | 60 days after receiving the deposit |

Specifications

PP film blowing machine`s product features with good insulation,hot-sealing,low temperature resistance, mechanical performance

FEATURES:

1) This Water-cooled PP Film Blowing Machine Combined machine head with two-layer extrusion, lower blowing water (rapid) cooling, rotation of mould head

2) Good insulation, sealing, transparency, cooking, fresh-keeping, hot-sealing, and printing and other performance

3) The product produced by the machine features with good insulation, hot-sealing, low temperature resistance and mechanical performance.

Model | 2G-XSJ45/45-FMJ800 | 2G-XSJ55/55-FMJ1000 | 2G-XSJ65/65-FMJ1200 |

Max. Folded Film Width | 700mm | 800mm | 1000mm |

Film Thickness | 0.02~0.12mm | 0.02~0.12mm | 0.02~0.12mm |

Output | 60kg/h | 80kg/h | 100kg/h |

Raw Material | PP,LDPE,LLDPE | ||

Screw Diameter | 2XΦ45mm | 2XΦ55mm | 2XΦ65mm |

Screw L/D | 228:1 | 228:1 | 228:1 |

Total Power of the Machine |

~73kw |

~88kw |

~103kw |

Shape Size(LxWxH) | 6.0x1.8x4.0m | 6.7x2.5x4.5m | 7.2x3.0x5.0m |

Weight | ~4500kg | ~5700kg | ~6500kg |

Correct specifications depend on the actual model all spcifications are subject to change without prior notice | |||

- Q: What is the working vacuum in the oil filter?

- The existing vacuum oil filter machine technical indicators only vacuum oil filter and coalescence vacuum oil filter two, so to answer this question, you need to understand the principle of vacuum oil filter, vacuum oil filter machine work, need to vacuum oil filter in the outside atmospheric pressure and oil filter in the vacuum pump under the action of the suction filter, large particle impurities are removed by the oil heater into the precision filter, filter the impurity particles fine before entering the water filter, separated out from the oil droplet, the precipitation in the water reservoir. The oil solution for removing impurities and large water drops enters a three-dimensional vacuum flash tower for further treatment of micro water.

- Q: Which filter is the best for peanut oil filter?

- The peanut oil filter is divided into centrifugal oil filter, plate and frame oil filter and vacuum oil filter

- Q: Seeking a set of oil filter drawings, the effect of good points, thank you, you can discuss

- Oil filter related drawings are numerous, there are structural schematics, technical principles, flow charts, electrical control charts, electrical schematics, etc., you do not say clearly what you need.If you need an inquiry oil filter, you can look for the relevant enterprise and let them send it to you

- Q: What is the optimum oil temperature of vacuum oil filter?

- 3. when the vacuum reaches -0.08Mpa, open the intake valve 15 to make it into the oil.

- Q: Can centrifugal oil filters filter sesame oil? What's the filtration effect?

- Filter effect is to see what you use the filter, and see you want to filter to what extent, generally need to consult with suppliers ah

- Q: Vacuum dewatering oil filter and coalescence separation dehydration, which dehydration effect is strong?

- Vacuum dehydration oil filter, this is not clear what you say is dehydration, and if it is coalescence separation, then the same effect as coalescence dehydration. If it is centrifugal, heating, sedimentation and other dehydration methods, there will be different effects.Vacuum dehydration oil filters are in fact a general term for negative pressure power supply. What you should know is what method of dehydration is used If it is the coalescing filter, then it is the poly series dehydration product, but the direction of the power is different.

- Q: Why does the oil filter run out of vacuum? How can we solve it?

- The oil filter in the operation process, occurring commonly used vacuum pump oil phenomenon, this is because the oil in the water too much, vacuum pumping, lead to a bubble too much, and some manufacturers of vacuum oil filter machine is not installed on the oil filter with automatic defoaming device, resulting in excessive foaming due to vacuum separator. The oil ejected from the exhaust of the vacuum pump in the mouth

- Q: The function of filter paper for plate oil filter

- There is no oil filter to intercept the impurities like a sieve, and the plate and frame oil filter is a pile of scrap metal

- Q: What's the function of a centrifugal oil filter?

- Because the use of mixed liquid (cloudy) with light and heavy liquid and solid density and immiscible, in centrifugal force field or different settling velocity in the gravity field principle of the separation layer or the precipitation of solid particles in liquid purpose.

- Q: The difference between plate type oil filter and automatic slag filter

- The plate and frame need to change the filter paper and filter cloth manually, but there is no residual oil, and the filter area of the same type is larger than that of the automatic slag can! Automatic discharge does not need filter paper, filter, automatic slag discharge, but more than oil, high oil yield no more than 80KG large frame.

Send your message to us

Two-layer Co-extrusion Down-ward Water-cooled Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords