Tri-dimension Compound Geonet/ 3D Composite Geonet for Drainage/ Drainage Tri-dimension Composite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

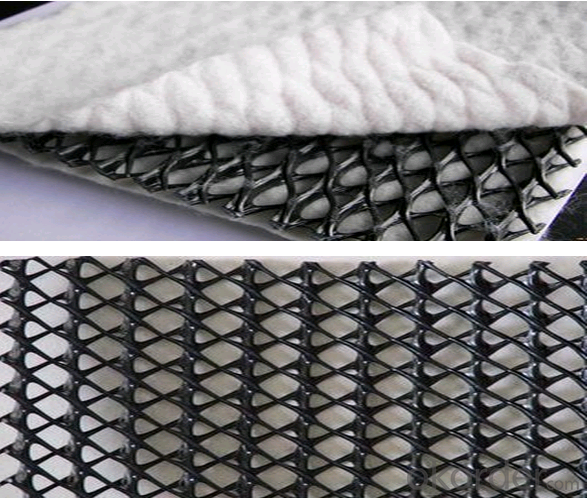

Tri-dimension composite genet for drainage is a new type of geosynthetics.

Its made of atri-dimension geonet coated with geotextile on both sides. Network core consists of a tri-dimension

thick vertical rib, and a rip on top and bottom .

It can drain underground water quickly, also there is a protection system,which can block the capillary water under high load. At the same time, it can also reinforce and isolate of foundation.

Product Uses

1,Landfill drainage;

2, Roadbed and road drainage;

3,Railway drainage, tunnel drainage, underground structure drainage.

4,The retaining back wall drainage,

5,gardens and sports grounds drainage

Functions

Excellent drainage function, can bear long time hige press load

High tensile and shear strength

Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

Tri-dimension composite geonet for drainage can bear more than kpa compression load

Its anti-compression capacity is much larger than common geonet for drainage.

Project | Index | |||

GL | GH | |||

GL-1 | GL-2 | GH-1 | GH-2 | |

Tensile strength (MPa) | ≥14 | ≥17 | ≥14 | |

Break elongation (%) | ≥400 | ≥450 | ≥400 | |

Right angle tear strength (N/mm) | ≥50 | ≥80 | ≥50 | |

Carbon black content (%) | ≥2 | |||

Water vapor permeability coefficient (g.cm/(cm.s.Pa) | ≤1.0x10-12 | |||

-70 Low temperature brittleness properties | pass | |||

Dimensional stability (%) | ±3 | |||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Is electrothermal?film safe?

- Electrothermal?film system has extremely high security, having no security risk, which is a very mature product. After testing by related departments, its insulation grade, voltage endurance capability, leakage current, flame resistance have reached the corresponding national standards.

- Q: Which one has lower cost between geomembrane and composite geomembrane?

- The cost of geomembrane of equal weight is higher than that of composite geomembrane, geomembrane texture HDPE, composite geomembrane texture LDPE+PET, the current market price HDPElDPE difference, PET is cheaper than HDPE

- Q: Are geomembranes resistant to bacterial growth?

- Yes, geomembranes are generally resistant to bacterial growth due to their impermeable and non-porous nature, which creates a barrier preventing the infiltration of bacteria.

- Q: How to fix template by pouring concrete after laying geomembrane?

- 1, start pouring room, finished room 2, mix proportion condition on the site: Cement: Sand: Stone: Water: 3, Metering conditions on the site: cement lack of KG sand lack of KG stone lack of KG water lack of KG (plus vehicle weight case) concrete step exemption 4, concrete slump casual inspection does not comply with the requirements of mix proportion 5, record the number of sets of concrete specimen and intensity of the construction unit; 6, record pouring thickness of cusion layer, elevation condition and pouring sequence (which axis)

- Q: How do geomembranes compare to traditional concrete or clay liners?

- Geomembranes are a more flexible and cost-effective alternative to traditional concrete or clay liners. They provide superior impermeability, preventing leakage of liquids or gases, and can be easily installed in various shapes and sizes. Unlike concrete or clay liners, geomembranes are lightweight, require less maintenance, and have a longer lifespan. Additionally, geomembranes are resistant to chemical degradation and can be customized to meet specific project requirements.

- Q: Which one is better, oil heater or electrothermal?film?

- The oil heater is heated slowly and will take up the space. The electrothermal?film is heated quickly and its heat range is large. The biggest advantage of it is that it does not take up any interior space as it is laid directly under the floor. It a good chioce for getting warm in winter. Meanwhile, the far-infrared carbon fiber of the electrothermal?film can as can effectively promote blood circulation. It is healthy and environmentally friendly!

- Q: What are the advantages of using geomembranes in biogas systems?

- There are several advantages of using geomembranes in biogas systems. Firstly, geomembranes act as a barrier, preventing the leakage of biogas into the surrounding environment, thus reducing the risk of greenhouse gas emissions. Secondly, they help in the retention and concentration of biogas, improving the overall efficiency of the system. Additionally, geomembranes are durable and resistant to chemical degradation, ensuring a longer lifespan and lower maintenance costs. Lastly, they provide flexibility in system design, allowing for easy installation and customization according to specific project requirements.

- Q: What are the standards and regulations governing geomembrane use?

- The standards and regulations governing geomembrane use vary by country and region. However, some common standards and regulations include ASTM D5199, ASTM D7408, and GRI-GM13. These standards provide guidance on the design, installation, and performance requirements of geomembranes, ensuring their proper use in various applications such as environmental containment, water management, and civil engineering projects. Regulatory bodies and industry organizations also play a role in establishing guidelines and enforcing compliance with these standards to ensure the safety and effectiveness of geomembranes in their respective jurisdictions.

- Q: Can geomembranes be used in aquaculture facilities?

- Yes, geomembranes can be used in aquaculture facilities. They are commonly used as liners in ponds, tanks, and raceways to prevent seepage of water and to protect the environment from potential contamination. Geomembranes provide a reliable barrier that helps maintain water quality and prevent the loss of valuable resources in aquaculture operations.

Send your message to us

Tri-dimension Compound Geonet/ 3D Composite Geonet for Drainage/ Drainage Tri-dimension Composite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords