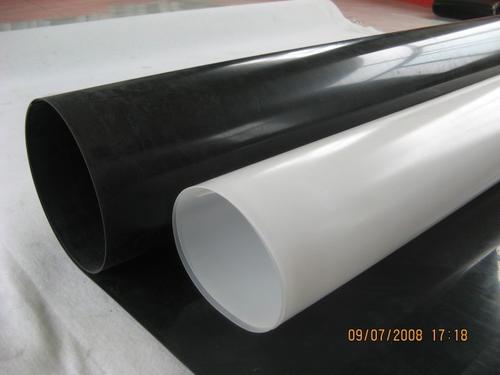

Solmax HDPE Geomembrane for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Geomembrane for Road Railway Highway Tunnel

Made of polyolefin based on the Xavan® Product.

Specification of HDPE Geomembrane for Road Railway Highway Tunnel

I. Thickness: 0.5mm

2.2m - 4m in roll width, the length as client ' s request

Property of Tpo Geomembrane for Road Railway Highway Tunnel

I. Light weight

2. Anti-aging, high strength and easy for construction

3. Good flexibility under temperature of -450C-950C

4. Excellent peel strength under low temperature

Application of HDPE Geomembrane for Road Railway Highway Tunnel

I. Fish pond, stream, swimming pool

2. Aquiculture

3. Golf course, ski field, artificial la ke

4. Landfill, waste water treatment

5. Artificial wetland

6. Water conservancy project

7. M u nicipal p roject

8. Agricultu re (channel, irrigation la ke, methane to n k)

9. Reclaim land from the sea and Saline alkali soil improvement

- Q: how to brush wallpaper basilemma

- First diluted the basilemma with pure water, and then follow the basilemma: Water =1: brushing for 1.5 or two times, the main processing steps of wallpaper base layer: 1, ensure the moisture content of the wall base layer should below the 8%----10%. 2, the wall before putty fumbling in a level should be firm, having no saltpetering, empty and loose. 3, after clearing the wall attachments, on the base level scrape putty 2-3 times, after abrasive?paper polished, clean the surface with gauze. 4, painted wallpaper basilemma, the wallpaper basilemma brushing the wall to dry after construction again. 5, construct on the surface of the wall which has been painted with wall paint, and you can not paste wallpaper directly on the wall, and then stripped off the original base layer putty, painted wallpaper basilemma, pasting after the paint drying. 6, old building has construction on the old wall, and the wall is not flat, not very nice to post wallpaper and it needs another special treatment before pasting.

- Q: Can geomembranes be used for decorative ponds?

- Yes, geomembranes can be used for decorative ponds. They are often used as liners to prevent water leakage and maintain the shape and integrity of the pond. Additionally, geomembranes come in various colors and textures, allowing them to blend seamlessly with the surrounding landscape, enhancing the aesthetic appeal of the pond.

- Q: How thick is the film for furniture? how to differentiate the home film from other films.

- Probably 200 microns thick Ha. Nano-ceramic furniture protective film, referred to as furniture foil, translucent, repairing minor scratches, fire high temperature (225 degrees), radiation (stone furniture), easy to clean, long life, in line with modern green healthy fashion requirements and so on. Applies to: Homes, offices, restaurants, hotels, large and small restaurants, furniture and other ancillary companies. Nano-ceramic film of high transparency furniture, furniture can fully reflect the desktop pattern and color, permanent protection as new. Nano-ceramic furniture foil insulation and ultra-high wear-resistant, so that when you use the desktop will not worry about the furniture scratches and scorch the paint. Nano-ceramic film good decontamination furniture, non-stick oil, smooth surface, do not move, easy to clean. Nano ceramic furniture film does not affect the character of furniture and furniture performance of the premise, to provide protection to the furniture. Nano furniture foil, is the use of high-grade super-transparent polymer with a number of precious metals (such as silver) joint action by sputtering indium oxide, the outer layer of an acrylic-based transparent, very tough. This produced a film with high transparency and heat insulation effect, the surface is very wearable. Nano-ceramic film of high transparency furniture, furniture can fully reflect the desktop pattern and color, permanent protection as new. Nano-ceramic furniture foil insulation and ultra-high wear-resistant, so that when you use the desktop will not worry about the furniture scratches and scorch the paint. Nano-ceramic film good decontamination furniture, non-stick oil, smooth surface, do not move, easy to clean. Nano furniture foil under furniture without affecting the character and performance of the premise of furniture, furniture protection, is the best protector of furniture.

- Q: What are the considerations for geomembrane selection in industrial storage facilities?

- When selecting a geomembrane for industrial storage facilities, several considerations should be taken into account. Firstly, the chemical compatibility of the geomembrane with the stored materials is crucial to prevent any potential leakage or contamination. The desired strength and durability of the geomembrane must also be considered to ensure it can withstand the environmental conditions and potential mechanical stresses in the facility. Another important factor is the installation ease and efficiency, as well as the geomembrane's ability to be inspected, maintained, and repaired if necessary. Additionally, cost-effectiveness and long-term performance should be evaluated to make an informed decision on the most suitable geomembrane for the specific storage facility.

- Q: What are the differences between reflective paint and reflective membranes?

- Reflecting paint is a novel reflective coating with acrylic acid resin as basic material, which is compounded with retro-reflective materials in the solvent in a certain proportion. The reflection principle is that the light is reflected back to people's sight through the reflective beads, and the reflection is more obvious at night. Reflective membrane is a new reflective material which is a combination of the reflection layer formed by glass beads with special techniques, and PVC, PU and other polymer materials.

- Q: Are geomembranes resistant to animal and insect damage?

- Yes, geomembranes are generally resistant to animal and insect damage due to their durable and impermeable nature.

- Q: What are the standards of geotechnical test methods?

- 1, drying method: Measuring the water content. 2, cutting-ring method, sand cone method: Measuring its density. 3, Pycnometer method: Measuring specific gravity of soil particle 4, statocone tyoe liquid limit device method, method of liquid-plasitc combined tester: Test of marginal moisture content 5, compaction test: Measuring the optimum water content 6, infiltration test: Test of permeability coefficient 7, direct shear test: Test of shear strength 8, triaxial?test, unconfined compression strength test: Measuring mechanical strength of the soil sample 9, consolidation test: Test of properties of soil consolidation

- Q: How do geomembranes contribute to lining of industrial ponds?

- Geomembranes contribute to the lining of industrial ponds by providing a strong and impermeable barrier that prevents leakage and contamination of surrounding soil and groundwater. They enhance the integrity and durability of the pond lining, ensuring efficient storage and containment of hazardous or toxic materials, wastewater, or any other industrial liquids. Additionally, geomembranes help regulate the evaporation rate of the pond, reducing water loss and maintaining proper liquid levels.

- Q: What is the difference between the primer and the basilemma?

- Compared with the common primer, basilemma has the feature of perfect transparency and no hiding power. You don't have to worry about the workability and finishing effect. In brief, good latex?paint primer is equivalent with basilemma (wallpaper primer). But it is of high price. So it is not recommended. But if the price of your basilemma is much higher than latex?paint primer, it's better to choose the transparent sealing latex?paint primer with better quality as the wallpaper sealing primer. But in contrary, perfectly transparent wallpaper primer (wallpaper basilemma) can't take the place of the latex paint primer.

- Q: Geomembrane anti-corrosion?

- Geomembrane has a variety of materials made of high quality PE made of geomembrane corrosion resistance of the best, the general strong acid and alkali and salt have a good resistance, the essence of PE chemical inertia. Hazardous waste landfills require the use of PE geomembrane for impermeability. If the production of geomembrane PE material is poor or doped with other materials, this performance is greatly discounted.

Send your message to us

Solmax HDPE Geomembrane for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords