Jual Self Adhesive HDPE Geomembrane Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

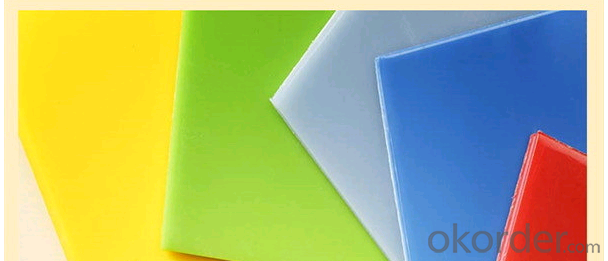

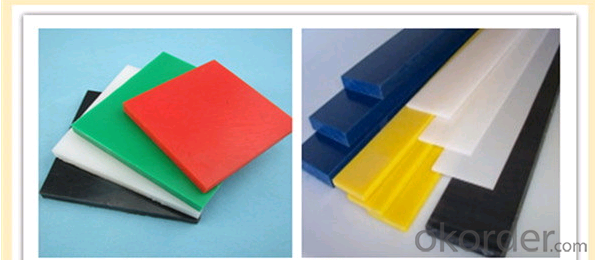

Description of self adhesive hdpe geomembrane sheet:

HDPE is a non polar thermoplastic plastic with high crystallinity and perfect electrical properties,especially the high insulation dielectric strengh.This polymer is non-hygroscopic which can be used to packing with good waterproof steam.HDPE with Middle to high molecure weight have good impact resistance at normal temperature even in the zero 40 degree Celisius.

Its surface won't wrinkle and is weather resistant.Because it is durable it has a long service life and acts as a flexible hinge that won't break.Our HDPE sheets can be customes produce to match specific colors,thickness,size and finish.

Advantages of self adhesive hdpe geomembrane sheet:

high insulation dielectric strength

perfect impact resistance

good heat /cold endurance

no toxic

excellent chemical resistance

low water absorption

good temperature properties

great chemical stability

Parameter of HDPE

| density(g/cm3) | 0.91-0.95 | Brittle Temperature(°c) | <-120< span=""> |

| water absorption(%) | <0.01< span=""> | Linear expanding coefficient | 1213 |

| in-process shrinkage(%) | 1.55.5- | Thermal conductivity(W/(m.k)) | 0.44 |

| tensile strength(Mpa) | 21-37 | Volume resistivity(Ω.cm) | 61015 |

| breaking extension(%) | >880 | Dielectric constant(106HZ) | 2.34-2.35 |

| Bending strength(Mpa) | 11 | Dielectric dissipation factor | 0.0003 |

| compressive strength(Mpa) | 10 | Dieletcric strength/(Kv/mm) | >20 |

| impact strength(KJ/m²) | 4070 | Arc resistant/s | 115 |

| Rockwell Hardness | R70 | Oxygen index(%) | 20 |

| Heat formation temperature(°c) | 75 |

Packing and Delivery

| Packaging Details: | self adhesive hdpe geomembrane sheet packing: By pallets or according to your request |

| Delivery Detail: | 10-15days after your deposite |

Why Choose US

1 More than 10 years professional manufacturing experiences with own factory

2 Perfect quality with 100% virgin material

3 Any color and size can be provided with your request

4Competitive price,fast delivery,excellent service

FAQ

1Why use HDPE sheet?

HDPE Sheet has an almost waxy feel to it and is pretty good at being a low friction wear strip material and is used probably more than any other plastic as a wear strip on conveyors or production lines of huge companies.

2When can I get the HDPE price?

After getting your inquiry,the reply will be send to you in 8 hours at most.If you are urgent to get the price,pls call us or tell us in the email so that we will regard your inquiry priority.

3.How long can I expect to get the sample?

After learning all the requirments of the sample clearly,those itmes will be send to you via express which will take 3-5working days.You can use your own express account or prepay us if you do not have an account.

- Q: how is the effect decoration color film.

- Very good! Color film is a new reinforced glass decorative materials, color film broke the previous traditional process that uses major pictorial material to strengthen the glass as decorative materials, replacing an enhanced pictorial material that dominated the glass sliding doors, glass cabinets, glass and other glass decorative backdrop materials. Glass color film with enhanced pictorial material no advantage: 1, color film made of tempered glass finished glass has high safety, after such a color film glass glass products, when the product was crushed, no glass fragments It will be like the usual glass littered, but all the pieces are glued to the glass color film, so you can ensure the safety of users guarantee the broken glass. 2, tempered glass color film having a high environmental protection. In the past pictorial material reinforced with glass, many of which are reinforced by a number of pictorial material volatile substances and toxic substances to be made, the finished product is made with an very strong toxic, not only to the workers this long accumulated in the processing of glass easy poisoning, after which the user in such a room to stay for a long time are likely to be poisoned at varying degrees , while the glass color film is the application of advanced inks and more environmentally friendly material, and has no toxicity.

- Q: Is silicon crystal electrothermal?film heater good?

- It has heating speed, not dry, but the speed is slower than ordinary electrothermal film. The biggest advantages of silicon crystal electric heating plate or tube is that infrared?ray radiation is stronger than heating?wire and electric heating quartz tube, so it has rapid heating rate without any pollution. On the market, however, there are silicon plates that are heated indirectly by heating?wire instead of electrifing, which are similar to electrical heating quartz tube. The main drawback of silicon crystal heating plate is that the electrifying port is prone to oxidize, causing poor contact. It is more appropriate to use 20 square metres and above 2000 watts silicon crystal. If the power is too low, heating effect is not very good and it is demanding.

- Q: Are geomembranes resistant to chemical spills?

- Yes, geomembranes are designed to be resistant to chemical spills. They are typically made of materials like high-density polyethylene (HDPE), which have excellent chemical resistance properties. This allows geomembranes to effectively contain and prevent the penetration of various chemicals, ensuring their durability and effectiveness in protecting the environment.

- Q: What are the design considerations for geomembranes in landfill construction?

- There are several important design considerations for geomembranes in landfill construction. Firstly, the geomembrane material should be chosen carefully, considering factors such as chemical resistance, durability, and flexibility. It should be able to withstand the harsh conditions of a landfill, including exposure to chemicals, gases, and punctures from waste materials. The thickness of the geomembrane is also a crucial consideration. It should be thick enough to provide sufficient barrier properties and prevent leakage of contaminants into the surrounding environment. The thickness should be determined based on the specific requirements of the landfill, including the type and quantity of waste being deposited. Additionally, the design should include proper anchorage and sealing methods to ensure the geomembrane remains securely in place and maintains its integrity. This may involve using anchor trenches, batten strips, or other techniques to prevent uplift and lateral movement. Furthermore, proper installation techniques and quality control measures are essential to ensure the geomembrane is installed correctly and without any defects. This includes proper surface preparation, seam welding or bonding, and regular inspection during and after installation to identify and address any issues. Lastly, the design should incorporate considerations for slope stability, settlement, and erosion control. The geomembrane should be designed to withstand the potential pressures and movements associated with the landfill slopes, as well as prevent erosion from stormwater runoff. Overall, the design considerations for geomembranes in landfill construction revolve around selecting the right material, determining the appropriate thickness, ensuring proper installation and maintenance, and addressing factors related to stability and erosion control. These considerations are crucial to ensure the effectiveness and long-term performance of the geomembrane liner system in landfill construction.

- Q: What are the considerations for geomembrane selection in oil and gas pipeline corrosion protection?

- When selecting a geomembrane for corrosion protection in oil and gas pipelines, several key considerations should be taken into account. Firstly, the geomembrane material should be resistant to the specific chemicals and substances present in the oil and gas industry, such as hydrocarbons and corrosive gases. It should also have excellent resistance to UV radiation, as pipelines are often exposed to sunlight. Additionally, the geomembrane should have high puncture resistance to protect against potential damage during installation or operation. The geomembrane's flexibility is another important factor, as it should be able to accommodate any movement or settlement in the pipeline without tearing or cracking. Finally, the geomembrane's longevity and durability should be assessed to ensure it can provide long-term protection against corrosion.

- Q: Which one has lower cost between geomembrane and composite geomembrane?

- The cost of geomembrane of equal weight is higher than that of composite geomembrane, geomembrane texture HDPE, composite geomembrane texture LDPE+PET, the current market price HDPElDPE difference, PET is cheaper than HDPE

- Q: Are geomembranes suitable for decorative purposes?

- No, geomembranes are not typically suitable for decorative purposes as they are primarily used for functional purposes such as containment, lining, and protection in various engineering and environmental applications.

- Q: How do geomembranes prevent water ingress in tunnels?

- Geomembranes prevent water ingress in tunnels by serving as a waterproof barrier. These synthetic liners, made from materials like HDPE or PVC, are installed along the tunnel walls and floor, effectively sealing off the tunnel from any groundwater or surface water. This prevents water from seeping into the tunnel, protecting the structural integrity of the tunnel and its surrounding environment.

- Q: What are the considerations for geomembrane selection in agricultural waste storage?

- Some considerations for geomembrane selection in agricultural waste storage include the type and composition of the waste being stored, the potential for chemical interactions between the waste and the geomembrane material, the desired lifespan and durability of the geomembrane, the presence of any potential hazards or contaminants in the waste, the installation and maintenance requirements of the geomembrane, and the cost-effectiveness of the chosen material.

- Q: Can geomembranes be used for landfill capping?

- Yes, geomembranes can be used for landfill capping. They are often used as a barrier to prevent the infiltration of rainwater and the escape of gases from the landfill, providing a reliable and effective solution for capping landfills.

Send your message to us

Jual Self Adhesive HDPE Geomembrane Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords