Transparent Aluminum Sheets Size - Aluminium Checkered and Mirror Sheet in Our Warehouse with Better Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

CNB, INTERNATIONAL CORPORATION's aluminum sheet and chekcered sheet and chekcered plate are all widely used in the field of Aluminum checkered sheet and mirror sheet and best-selling price with shortest delivery time, sheet is widely used in the field of industrial construction field and other details of decoration field, etc.

There are alloy nubmer: 6000 series,7000series, 8000 series, etc. The detailed grade are as 3003, 5052,5754,6061,6063,8011, etc.

The temper is include O, F,H12,H14,H24,H111, H44,H112, H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

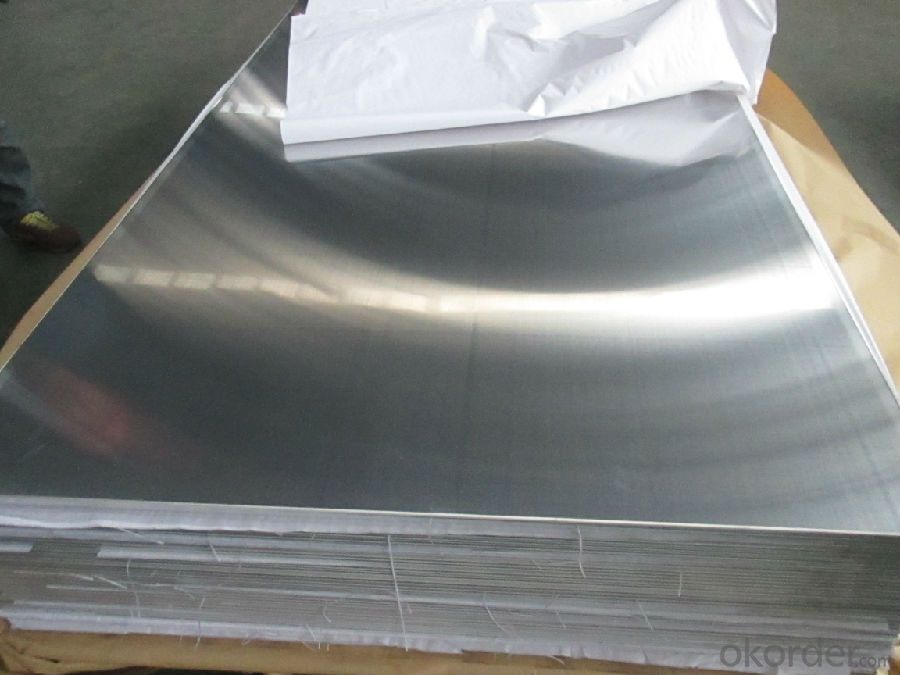

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1219mm*500MM,1000*1000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 500mm to 2500mm, etc.

What is the length range:

---It is from ur products yet?

---Normally it is around 2 tons/each size.

How many tons did you export in one year?

---totally.Where is your client from?

---Normally it is from Pakistan,Saudi Arabia, BANGLADESH,PAKISTAN,FIJI, England,Tu,etc.

What is big-5-bar aluminium checkered sheet,small-5-bar aluminium checkered sheet,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What are the special coatings or treatments available for enhancing the properties of aluminum sheets?

- <p>Yes, there are several special coatings and treatments that can be applied to aluminum sheets to enhance their properties. These include anodizing, which creates a protective oxide layer, powder coating for a durable and colorful finish, and thermal spraying for improved wear resistance. Other treatments involve chemical conversion coatings, such as chromate conversion, which provides corrosion resistance, and various types of plating like electroplating or hot-dip galvanizing for added strength and protection. These treatments can significantly improve the appearance, durability, and performance of aluminum sheets in various applications.</p>

- Q: What specific conditions or criteria need to be met when installing aluminum windows to ensure they are properly fitted and functional?

- <p>When installing aluminum windows, there are several special requirements to consider: ensuring the frames are level and square, using the correct size and type of fasteners, applying a proper sealant to prevent air and water infiltration, and adhering to local building codes. Additionally, it's crucial to check for thermal insulation properties, especially in areas with extreme weather conditions. The installation should also allow for proper drainage to prevent water damage. Professional installation is often recommended to meet these requirements and ensure the windows function correctly and last longer.</p>

- Q: i need to know these things please....can aluminium withstand the forces of being in a cargo hold on a air freight, can it withstand extreme temps and to what extent an is it microwavable?? please help me

- No metals are microwavable, they will ruin any microwave oven by producing sparks. Even ceramic plates with a little metallic paint eg of silver will spark. Aluminium on its own has little strength but when mixed with small amounts of eg copper or manganese it aquires great strength while remaining light. In addition it has the advantage of being very resistant to oxidation and corrosion. It is certainly used extensively in aircraft construction. Due to being non toxic it used to make cans for beers, soft drinks (sodas) etc However it doesn't stand up well to high temperatures, its melting point is just at 660 degrees celsius, by comparison for iron it is 1540 and tungsten 3420.

- Q: How do aluminum sheets perform in extreme weather conditions?

- Aluminum sheets are known for their exceptional performance in extreme weather conditions. Due to their inherent properties, aluminum sheets are highly resistant to corrosion and can withstand harsh environmental elements such as rain, snow, and extreme temperature fluctuations. In hot weather, aluminum sheets have the ability to reflect sunlight and dissipate heat, preventing them from warping or deforming. This makes them well-suited for use in areas with high temperatures or direct exposure to sunlight. Similarly, in cold weather, aluminum sheets do not become brittle or lose their strength, making them reliable in freezing temperatures or areas prone to heavy snowfall. They have a low coefficient of thermal expansion, meaning they can withstand contraction and expansion without cracking or becoming damaged. Furthermore, aluminum sheets have excellent resistance to moisture, preventing them from rusting or corroding when exposed to rain or high humidity levels. This makes them ideal for use in coastal areas or regions with heavy rainfall. Aluminum sheets are also lightweight, yet durable, which allows them to withstand high winds and severe storms without compromising their structural integrity. This makes them a preferred choice for applications such as roofing, siding, and outdoor signage in areas prone to hurricanes or strong winds. Overall, aluminum sheets demonstrate remarkable performance in extreme weather conditions, making them a reliable and versatile material for various outdoor applications.

- Q: im wondering what happens if you MIG weld aluminum with the correct wire but without using a shielding gas? Would it just be extremely messy or does there HAVE to be an inert gas flowing for it to bond?thanks

- Mig Welding Aluminum Without Gas

- Q: I have some carbon arrows for my bow but I was wondering if aluminum arrows penetrate farther into a deer because they weigh more. I read somewhere that they do but I just wanted to confirm that.

- Aluminum arrows do not penetrate nearly as well as the carbon arrows do. The carbon arrows penetrate better due to the carbon arrow generating more speed then the aluminum arrow and the stiffness of the carbon arrow plays a factor in it's superior penetration. If you watch a slow motion video of an aluminum arrow striking a target, the arrow flexes several times upon impact. This absorbs some of the force of the arrow. Carbon on the other hand has almost zero flex when hitting the target, therefore all the power goes into Penetration. Another fact I found out when I made the switch to carbon arrows.They are actually cheaper to use then the aluminum.A dozen carbon arrows will last much longer then a dozen aluminum ones will.You can make an aluminum arrow worthless as a hunting shaft with a broad head on it by merely dinging it a little while target practicing.Or if it becomes bent even if unable to see with the naked eye will ruin it for use with a broad head. Carbon on the other hand will never bend or ding.They last forever unless a deer rolls over on it and breaks it. It took me forever to make the switch to carbon arrows, but once I did I will never go back to aluminum again.In the old days everyone thought that weight alone was the contributing factor to penetration. But now it has been discovered that speed and stiffness are even greater factors that contribute to penetration. Stick with the carbons.

- Q: Calculate the mass in grams of Iodine (I2) that will react completely with 20.4 g of aluminum to form aluminum oxide (AlL3)

- Aluminium oxide? Shouldn't it be Aluminium iodide? 1. Form a balanced equation 3I2 + 4Al - 2Al2I3 2. Number of moles of Al 20.4/(Mr of Al) = 20.4/27 = 0.7555mol 3. Number of moles of I2 0.7555/4 x 3 = 0.5666mol 4. Mass of I2 required = 0.5666 x Mr of I2 = 0.5666 x (127x2) Ans: 143.9164g

- Q: Can 101 aluminum sheets be used in electrical or electronic components?

- Yes, 101 aluminum sheets can be used in electrical or electronic components.

- Q: It seemed in my experiment that aluminum wasn't reactive at all in the displacement reactions, except with copper sulfate. Is there a reason? or did I make a mistake? aluminum is more reactive than e.g silver nitrate, why didn't it react with it?

- Aluminium has a protective coating of Aluminium Oxide, this prevents many chemicals reaching the surface. This is because aluminium has a very strong affinity for oxygen and bonds to it with extremely strong bonds. It can be removed by dipping it carefully into a solution of Mercury (II) Chloride.

- Q: Can aluminum sheets be plasma cut?

- Yes, aluminum sheets can be plasma cut. Plasma cutting is an effective method for cutting aluminum sheets as it utilizes a high-temperature plasma arc to melt and remove the metal, resulting in clean and precise cuts.

Send your message to us

Transparent Aluminum Sheets Size - Aluminium Checkered and Mirror Sheet in Our Warehouse with Better Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords