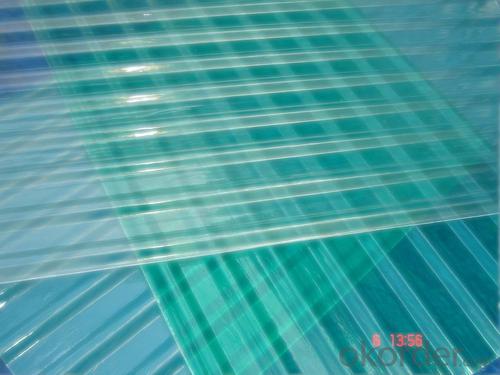

Translucent Polyethylene FRP Plastic Sheet Roof Skylight Panel Soundproof Steel Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

COMPANY INFORMATION

CNBM, China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china buiding materials industry. Established in 1984,CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products, professional service and complete solution to our customers. Strong delivery capacity, advanced technology & management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

INTRODUCTION

A roof is part of a building envelope. It is the covering on the uppermost part of a building or shelter which provides protection from animals and weather, notably rain or snow, but also heat, wind and sunlight. The word also denotes the framing or structure which supports that covering.

The characteristics of a roof are dependent upon the purpose of the building that it covers, the available roofing materials and the local traditions of construction and wider concepts of architectural design and practice and may also be governed by local or national legislation. In most countries a roof protects primarily against rain. A verandah may be roofed with material that protects against sunlight but admits the other elements. The roof of a garden conservatoryprotects plants from cold, wind, and rain, but admits light.

A roof may also provide additional living space, for example a roof garden.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATION

| Place of Origin: | Hebei, China(Mainland) | Brand Name: | CMAX |

| Model Number: | 2.5 mm | Material: | Synthetic Resin, Synthetic resin & ASA |

| Type: | Double Roman Tiles | Thickness: | 3 mm, 2.5mm, 2.3mm |

| Color: | Red or as customer require | Length: | as customer require |

| Width: | 1 meter | Density: | 1.685 g/CuNaN |

| Fire prevention: | B1 grade | Wave height: | 87.5px |

| Wave spacing: | 500px | Effecitve width: | 0.9m |

PICTURES

- Q: Can FRP roofing panels be recycled at the end of their lifespan?

- FRP roofing panels can indeed be recycled once they reach the end of their lifespan. FRP, a composite material composed of plastic resin reinforced with fibers like fiberglass, can be processed for recycling depending on the availability of recycling facilities in a given region. Recycling FRP panels involves grinding or shredding them into smaller pieces to separate the plastic resin from the fibers. These separated components can then be reused or repurposed for various applications. The plastic resin can be melted down and utilized in the production of new plastic products, while the fibers can be employed as reinforcements for concrete or other composite materials. It is important to note that not all recycling facilities are capable of handling FRP panels due to their composite nature and the difficulties involved in separating the plastic resin from the fibers. However, as the demand for sustainable practices and recycling of composite materials continues to rise, specialized recycling facilities dedicated to handling FRP and other composites are emerging. To ensure the proper disposal and recycling of FRP roofing panels, it is advisable to reach out to local recycling facilities or waste management companies to inquire about their capabilities and procedures for recycling FRP. Additionally, manufacturers and suppliers of FRP roofing panels may have specific recycling programs or partnerships in place to facilitate the recycling process.

- Q: Can FRP roofing panels be curved or molded?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be curved or molded to fit different architectural designs and shapes. The flexibility of FRP allows for customization and versatility in roofing applications, enabling the creation of curved or molded panels to meet specific project requirements.

- Q: Can FRP roofing panels be cut to fit specific dimensions?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be cut to fit specific dimensions. FRP panels are known for their flexibility and can easily be cut to the desired size using basic cutting tools such as a circular saw or a jigsaw. It is important to take appropriate safety precautions while cutting FRP panels, such as wearing protective eyewear and gloves. Additionally, it is recommended to measure and mark the dimensions accurately before cutting to ensure a precise fit. Overall, FRP roofing panels offer the convenience of customization, allowing them to be easily cut to fit specific dimensions as required.

- Q: Are FRP roofing panels resistant to high-pressure washing or cleaning?

- Yes, FRP roofing panels are generally resistant to high-pressure washing or cleaning. The durable and weather-resistant nature of FRP (Fiberglass Reinforced Plastic) makes it capable of withstanding high-pressure cleaning without sustaining damage or structural integrity issues. However, it is recommended to follow the manufacturer's guidelines and use appropriate cleaning techniques to ensure the longevity and optimal performance of FRP roofing panels.

- Q: Can FRP roofing panels be installed over existing roofs?

- In certain cases, it is feasible to install FRP roofing panels over pre-existing roofs. However, there are several factors that need careful consideration prior to proceeding with the installation. First and foremost, the condition of the current roof must be evaluated. If the roof is extensively damaged or has structural problems, it may not be suitable for the installation of FRP panels. It is advisable to engage the services of a professional roofer to conduct a thorough inspection and determine the roof's suitability for the installation. Secondly, the weight of the FRP panels should be taken into account. If the existing roof is incapable of supporting the additional weight, it could result in further damage or even collapse. Once again, it is essential to consult with a professional to assess the load-bearing capacity of the current roof. Furthermore, it is imperative to check the compatibility of the FRP panels with the existing roof. Different roofing materials may have varying rates of expansion and contraction, which could cause problems if the panels are not installed correctly or if they do not align properly with the existing roof structure. Lastly, local building codes and regulations must be considered. Certain jurisdictions may have specific requirements or limitations when it comes to installing new roofing materials over existing roofs. Complying with these regulations is crucial to ensure the safety and integrity of the roof. In conclusion, while the installation of FRP roofing panels over existing roofs is possible, it is vital to assess the condition of the current roof, evaluate its weight-bearing capacity, check compatibility, and adhere to local regulations. Seeking the guidance of a professional roofer is highly recommended to achieve a successful and secure installation.

- Q: Are FRP roofing panels suitable for parking structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for parking structures. They are lightweight, durable, and resistant to corrosion, making them ideal for withstanding the constant exposure to various weather conditions in open parking areas. Additionally, FRP panels offer excellent UV resistance, ensuring long-term performance and minimal maintenance requirements. Their versatility and ease of installation also make them a cost-effective choice for parking structures.

- Q: Can FRP roofing panels be walked on?

- To prevent damage, it is crucial to take certain precautions when walking on FRP (Fiberglass Reinforced Plastic) roofing panels. While these panels are designed to be sturdy and durable, cracking or breaking can occur due to excessive weight or improper handling. When walking on FRP roofing panels, it is essential to distribute your weight evenly by stepping on the supporting purlins or structural elements beneath the panels. Stepping directly on the unsupported areas should be avoided to minimize the risk of damage. Furthermore, wearing soft-soled shoes or boots is advisable to reduce the impact on the panels. It should be noted that FRP panels can become slippery in wet or debris-covered conditions, so extra caution should be exercised. Using safety equipment like harnesses or non-slip shoes can further enhance safety while walking on FRP roofing panels. Before attempting to walk on FRP roofing panels, it is recommended to refer to the manufacturer's guidelines or seek professional advice. This ensures that the specific type of FRP panel being used can withstand the intended weight and foot traffic. By following these precautions, the integrity of the panels can be maintained, and potential damage can be prevented.

- Q: Can FRP roofing panels be used for both indoor and outdoor applications?

- Yes, FRP roofing panels can be used for both indoor and outdoor applications. FRP panels are known for their durability, weather resistance, and versatility, making them suitable for various environments and applications, including both indoor and outdoor settings.

- Q: Are FRP roofing panels suitable for historical restoration projects?

- FRP roofing panels may not be the most suitable choice for historical restoration projects as they do not typically match the aesthetic and architectural characteristics of historic buildings. Traditional roofing materials such as slate, clay tiles, or wood are often preferred to maintain the historical integrity and authenticity of the structure.

- Q: Can FRP roofing panels be used in mobile homes?

- Indeed, mobile homes can utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess the qualities of being lightweight, durable, and highly resistant to weathering and UV radiation, rendering them appropriate for various applications, including roofing. They present a cost-effective alternative to conventional roofing materials and offer commendable insulation properties. Moreover, the installation of FRP panels is trouble-free, and their maintenance requirements are minimal, making them an optimal choice for mobile homes that prioritize mobility and convenience. Nevertheless, it is crucial to verify that the mobile home's structure is compatible with the installation of FRP roofing panels and to take all necessary precautions during installation to ensure adequate sealing and waterproofing.

Send your message to us

Translucent Polyethylene FRP Plastic Sheet Roof Skylight Panel Soundproof Steel Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords