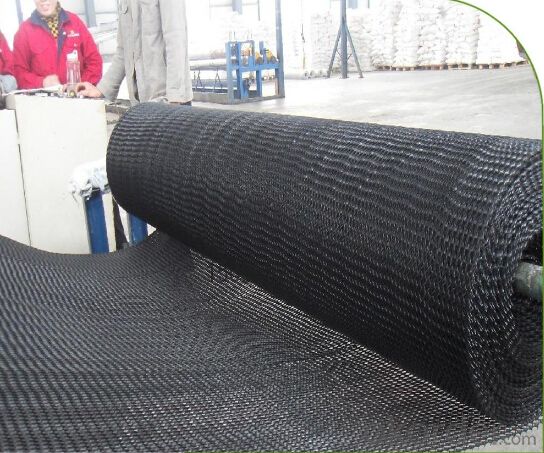

Tr-dimension Composite Geonet ;Drainage Geocomposites

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Drainage Geocomposite / Composite drainage geonet

Description :

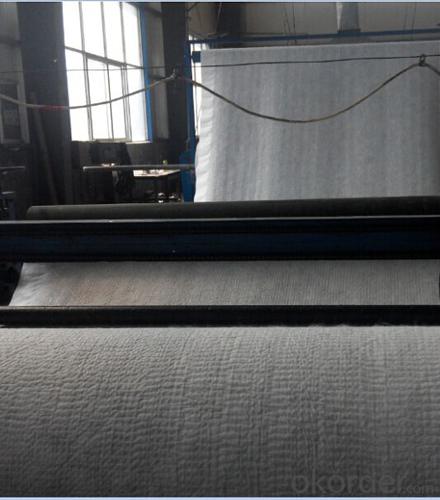

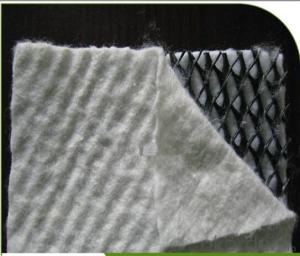

Drainage Geocomposites are engineered to replace costly, conventional open graded aggregate and/or perforated- pipe subsurface drainage systems. The Geocomposite Drainage is created by laminating a filtration geotextile on one or both sides of a Geonet. Geocomposite Drainages have reached acceptance as state-of-the-practice because they provide sufficient in-place drainage and offer reduced material cost, installation time and design complexity over conventional systems.

Application:

1) Landfill drainage;

2) roadbed and road drainage;

3) railway drainage;

4) tunnel drainage,

5) underground structure drainage,

6) the retaining back wall drainage;

7) gardens and sports ground drainage

Features:

1)Excellent drainage function, can bear long time hige press load

2)High tensile and shear strength

3Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

4)Tri-dimension composite geonet for drainage can bear more than 2000kpa compression load

5)Its anti-compression capacity is much larger than common geonet for drainage

6) Certificate :ISO14001:2004, ISO9001:2008

Specifications and technical parameters:

Drainage network core | units | Specification | ||||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 | |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 | |

Elongation | % | 50 | 50 | 50 | 50 | |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 | |

Geotextile | g/m2 | Heavier grades of geotextiles can be bonded to geonet on request | ||||

Usages:

In the railway, highway and other transportation infrastructure, drainage system safety and the service life

of the project and its have inseparable relationship, in which the geotextile material is an important part

of drainage system, the drainage effect of 3D composite drainage net is particularly notable. mainly

used for tunnels, municipal engineering, reservoir, revetment in drainage engineering.

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: What are the different types of earthwork products available in the market?

- There are several types of earthwork products available in the market, including topsoil, fill dirt, gravel, sand, and mulch. Each product serves a specific purpose in construction, landscaping, or gardening projects. Topsoil is used for creating a fertile layer for planting, while fill dirt is used to level or raise the ground. Gravel is commonly used for driveways, paths, and drainage systems, while sand is used for various purposes such as mixing concrete or bedding for pavers. Mulch is primarily used for landscaping to retain moisture, control weeds, and enhance the aesthetics of gardens and flower beds.

- Q: How do earthwork products contribute to habitat creation in urban areas?

- Earthwork products, such as soil and rocks, play a vital role in habitat creation in urban areas. They provide the necessary materials for constructing features like berms, terraces, and retaining walls, which can create diverse microhabitats. These structures not only offer shelter and protection for plants and animals but also serve as a foundation for the establishment of green spaces, including parks and gardens. Additionally, earthwork products help in the formation of ponds, wetlands, and other water features, which further enhance biodiversity and provide habitats for aquatic species. Overall, these products enable the transformation of urban landscapes into thriving ecosystems, supporting a wide range of plants and animals and promoting a healthier and more sustainable urban environment.

- Q: How do geotextile tubes aid in sediment dewatering in earthwork applications?

- Geotextile tubes aid in sediment dewatering in earthwork applications by effectively separating water from the sediment through the permeable geotextile fabric. As the sediment-filled tube is filled with water, the geotextile fabric allows water to pass through while retaining the sediment inside. Gravity and natural dewatering processes cause the water to drain out of the tubes, leaving behind dewatered sediment that can be easily managed and disposed of. This process significantly reduces the volume and weight of sediment, making it more cost-effective and environmentally friendly for earthwork projects.

- Q: What are the advantages of using geonets in geothermal energy systems?

- One advantage of using geonets in geothermal energy systems is their ability to enhance heat transfer. Geonets can be embedded in the ground to create a network of channels that efficiently distribute heat from the geothermal source. This increases the overall effectiveness and efficiency of the system, allowing for better utilization of the available geothermal energy. Additionally, geonets help to stabilize the ground, preventing subsidence and other ground movement issues commonly associated with geothermal energy extraction.

- Q: Are building materials the same as civil engineering materials?

- Civil engineering includes a wide range of materials, except for buildings, roads, bridges, tunnels and geotechnical materials that are related to civil engineering materials, but many of these materials are not used in industrial and civil construction.

- Q: What are the benefits of using geotextile tubes for shoreline restoration?

- Geotextile tubes offer numerous benefits for shoreline restoration projects. Firstly, they provide an effective and durable solution for erosion control, helping to stabilize the shoreline and prevent further degradation. Additionally, geotextile tubes are versatile and can be customized to suit specific project requirements, enabling flexibility in design and implementation. They are also cost-effective compared to traditional methods, as they require less labor and materials. Furthermore, these tubes are environmentally friendly, as they can be filled with locally sourced sediment, reducing the need for long-distance transportation and minimizing ecological disturbances. Overall, geotextile tubes are a reliable and sustainable option for shoreline restoration, offering long-term protection and preservation of coastal areas.

- Q: How do geopipes help in stormwater infiltration systems?

- Geopipes help in stormwater infiltration systems by effectively capturing and transporting stormwater runoff to designated infiltration areas. Their perforated design allows for efficient water drainage and prevents clogging, ensuring the smooth infiltration of stormwater into the ground. Geopipes also help distribute the water evenly across the infiltration area, minimizing the risk of localized flooding or erosion. Overall, geopipes play a crucial role in enhancing the functionality and effectiveness of stormwater infiltration systems.

- Q: What are the different thickness options available in earthwork products?

- The different thickness options available in earthwork products typically range from 2 inches to 12 inches, depending on the specific product and its intended use.

- Q: Are there any specific earthwork products available for wastewater treatment systems?

- Yes, there are specific earthwork products available for wastewater treatment systems. These include products such as geotextiles, geosynthetics, geomembranes, and geocomposites that are used for various purposes in wastewater treatment systems, such as filtration, erosion control, and containment.

- Q: How do segmental retaining walls provide stability?

- Segmental retaining walls provide stability through their unique design and construction. These walls are built using interlocking concrete blocks or stones that are stacked together in a specific pattern. This design allows for the transfer of lateral earth pressure from the backfill to the wall structure, preventing soil movement and maintaining stability. Additionally, these walls are reinforced with geogrids or steel reinforcements, which further enhance their strength and resistance to external forces. Overall, the combination of interlocking blocks and additional reinforcements ensures that segmental retaining walls can effectively retain soil and provide long-term stability.

Send your message to us

Tr-dimension Composite Geonet ;Drainage Geocomposites

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords