Tower Crane 4808 40T.M New Mini Crane in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

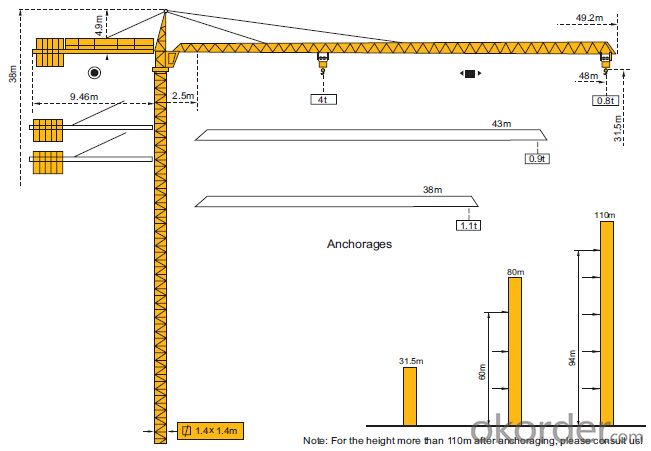

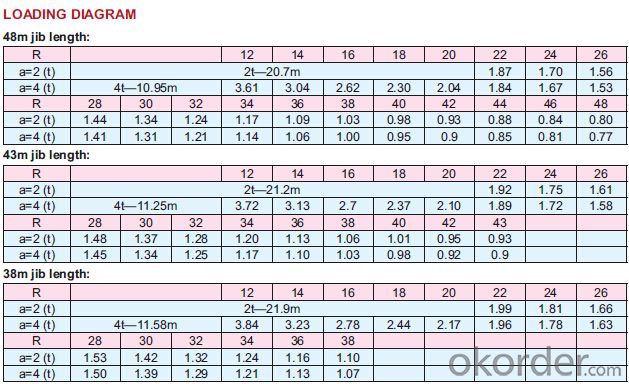

Detail of Tower Crane

Feature:Tower Crane Condition:New Model Number:TC4808(QTZ40) Place of Origin: China (Mainland) Brand Name: CMAX Certification: ISO,CE Warranty: 1 Year Application:Building,Construction,Industrial

Main Features of Tower Crane

1) This series of tower cranes, ranging from QTZ40 to QTZ400 has a horizontal jib frame, a jib-trolley radius-changing mechanism and a hydraulic self-raising mechanism. It is original in design, reliable in operation and satisfactory in shape. Equipped with all necessary safety devices, these cranes show a good speed-control capacity, satisfactory operating stability and high work efficiency. They can be widely used for the construction of high-rise hotels, residential buildings, high-rise industrial buildings, large-span factory buildings and tower-like buildings like tall chimneys.

2) It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed. 3)The range-change structure drives the trolley moving on the horizontal crang jib, with good positioning performance. Planet gear decelerator is applied in the circumgyrating structure, together with moment-limiting hydraulic coupler, which can relize high load capacity, steady starting and reliable operation.

4) The crane has complete set of safety devices, which can guarantee the safe and high efficienct operation. The crane is equipped with lifting height limiter, trolley ranging limiter, moment limiter, weight limiter etc..

5)The cranehas scientific layout and handsome appearance. The drivers cab is set independently on one side, with good vision field. It creates a good working environment for the operator.

Specification of Tower Crane

Images of Tower Crane

FAQ about Tower Crane

Q: What serice you could provide? A: Providing timely delivery, standby engineers are ready to slove any of your problem Providing all-embraced warranty of products quality, worksite installation guidance Providing ample spare parts and training of operation and maintenance Engineers have more than 20 years' experience in tower crane, ready to solve any of your problems.

Q: What kind of steel used for tower crane ? A: Normally, as for the main force bearing steel structure, Q345B is adopted; as for the assistance force bearing steel structure Q235B is adopted. All of the raw material is outsourced from qualified steel factory in China.

Q: What about our tower crane warranty? A: Usually there is one-year quality warranty including main electronic parts (not including consumable parts). There are consumable spare parts together with whole machine and normally they are enough for one year.

Q: What is 3 main mechanism of the tower crane ? A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer? A: Sure. All of these could be provided with extra cost upon the clients' requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view. | |||||

| (0) | |||||

- Q: HSE Officers can better answer this question or a qualified Crane operator it self can explain.

- each crane is so different. it depends on the rated crane load, the lifted distance from the crane and actuall load to be lifted. Each crane an envelope of angles to the horizontal, lifted load, and distance from the crane. The crane operator must insure that he is within this envelope or the crane may topple over. Also, the wind at the time of the lift must be considered. If you can picture a seesaw with loads pivoting about a fulcrum. When two people are on the seesaw, one person is the crane and the other is the load to be lifted. Only in the case of a crane, the fulcrum is at the crane itself with a large dead load counter weight behind the cab operator.

- Q: i know something is supposed to happen when you make a thousand origami cranes but i dint remember what happens. can someone please help me

- It's a story about a japanese girl who was diagnosed with leukemia. The story goes, if are diagnosed with leukemia and are able to fold a 1000 paper cranes before you die, you will live. This theory actually works the way horoscopes do. It's not that the making of paper cranes makes you healthy, it has to do with the amount of time it takes. If you survive that long, then you have passed the critical death points and will live anyway, whether you make a thousand of them or not. Plus, it gives you something to do a a healthy, short-term reason to live, which always helps the healing process anyway.

- Q: Do they have to be taken apart... if so, how are they taken apart... by another crane? - but how did that one get there etc etc

- it depends on the crane over the road mobile cranes drive them selfs to the job site and they have a dolly for the conter weights and then on the larger ones a semi brings in the conter weights. Then on a latise boom crawler crane it depends on the size of the crane if its a small one say a 150 ton crane the body and tracks can usally be moved together on a semi and the lattice boom will come on a seperate truck and is usally assembled with a all terrain fork lift. Then say on a larger crawler crane like a 500 tonner the body and tracks and carrige all come in seperate peices and are ussally put togther with a RT crane(more on the latter) and these cranes are held together with massive pins i saw a crew build a 400 ton manitowac crane with 150 feet of stick in less then a day. Now if they have to add more stick like say 200 feet of main stick and 150 feet of luffing jib they will build it all on the ground and then another crane will help lift the stick up Then there are RT cranes or rough terrain cranes they are moved on a semi to and from the job site and usally require no assebley thats all i know about i cant say how a tower crane is build iv never see one build hope this helps

- Q: I got the Fly crane TODAY and I never even flew it, but I charged it up and it wont fly. The blades spin for 5 seconds, and then stops.

- Good okorder , Funtastic Customer Service Team

- Q: I herd that there was some sort of legend that if you make a certain # of paper cranes you get a wish! Do you believe this to be true? Do you have to make 100 cranes or 1000 cranes?

- It sort of depends, maybe. And the legend says that it is indeed and unfortuantely 1,000 cranes. It also says you have to make all of these within a year, and it is a DIY project

- Q: In the case of tower crane operation, the operation should be stopped

- In case of six or more gales, heavy rain, heavy fog, heavy snow or tower crane, you should stop working

- Q: Please give a scripted answer. Funniest Denny Crane comment and action gets the 10 points

- Denny Crane. Now bring in the hookers. Did I mention I made Paula all she is..., was that just that I made Paula. Denny Crane Don't make me shoot you.

- Q: Is it through the rails? if so, then how? or is it by another method?

- Hot rails running along side the beams Hot shoes on the crane make contact with the hot rails and slide along the hot rails. Hot rails mounted to the beams by insulating bells. The hot rails can be anywhere in size from trolley wires to rails the size of railroad track rails. AC cranes are usually 3 phase so they will have 3 hot rails. DC cranes will usually have just 2 hot rails. Main disconnect/lock out feeds hot rails. It is usually fused but can also be just a disconnect switch. The same arrangement also is used on the crane's trolley. But in the case of the trolley one set of hot rails feeds the trolley motor. One set of hot rails feeds the main hook {big hook} motor: One set of hot rails feeds the auxiliary hook motor {little hook} motor. If the crane is also used as a Mag crane {Electro magnetic can be used} it will also have a set of hot rails going to the trolley for the magnetic

- Q: How do you apply for it? What are the specific requirements?

- This really did not hear, the site installed to be tested, usually installed, in accordance with the safety procedures, acceptance of the OK

- Q: The machine weight is 17500 KgEach crane capacity is 12500 KgThe lenght of beam is 4.5m and square cross section areaMaterial of beam is ASTM A 615 Gr60Machin connect to beam in 3 pointWhat is the beam cross section area dimension?

- You left out crucial information and working it out with risky assumptions takes too much work. Whatever this was supposed to mean Machin connect to beam in 3 point What is missing is whether the cranes connect to the end and the entire weight of the machine is in the middle - or is the machine attached at 3 distributed points. In addition, there has to be some condition - looking at the ASTM spec will give strength, but you have specified whether the beam is to be just at failure or 50% safety factor, etc.

Send your message to us

Tower Crane 4808 40T.M New Mini Crane in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords